Electric suction lock mechanism provided with three-stage lock positions

A lock mechanism and electric technology, which is applied in the field of automobile door locks, can solve the problems of large sealing force, easy opening of the tailgate, and potential safety hazards, so as to improve the accuracy and sensitivity of contact state changes, improve performance, and prevent bouncing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

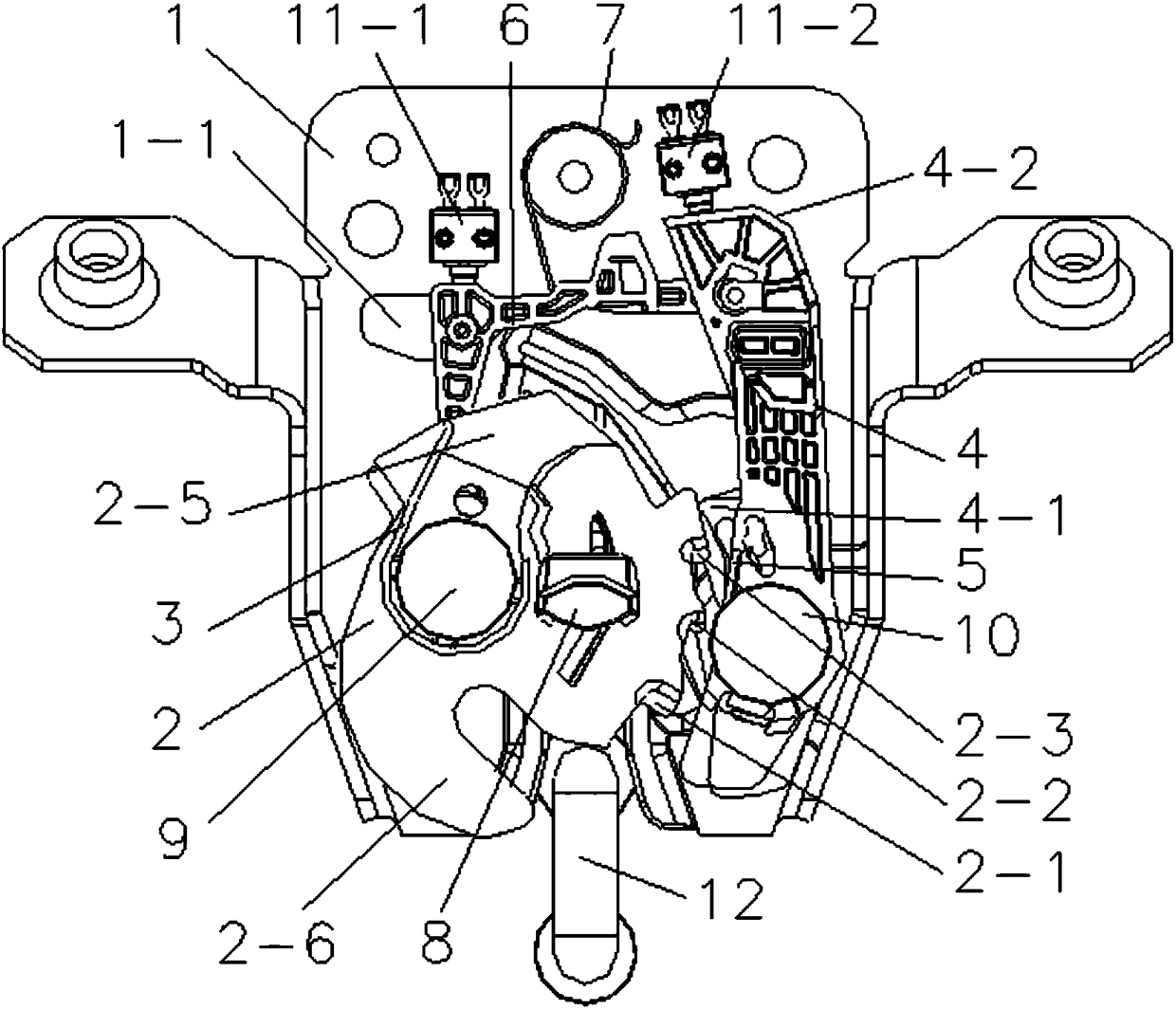

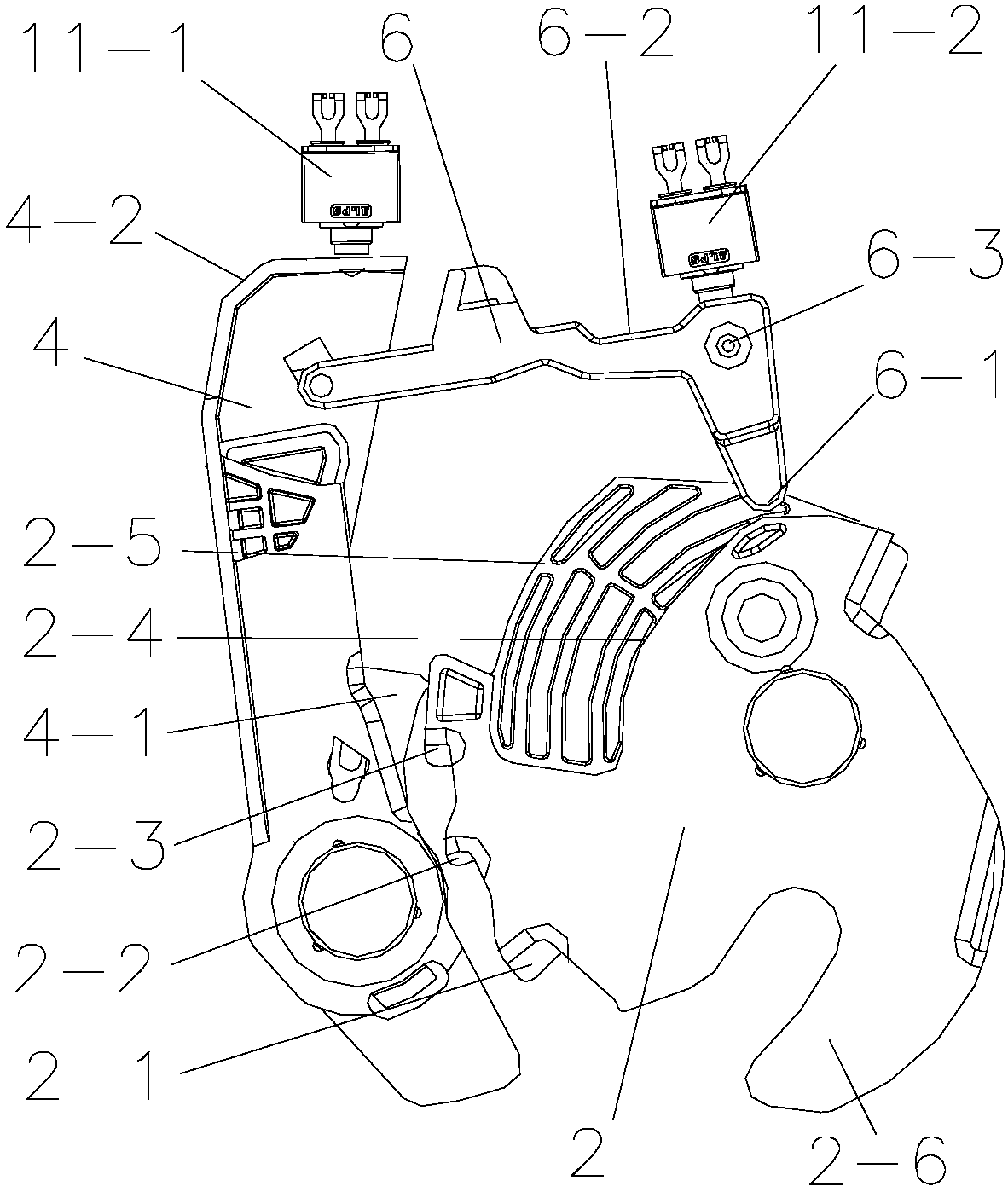

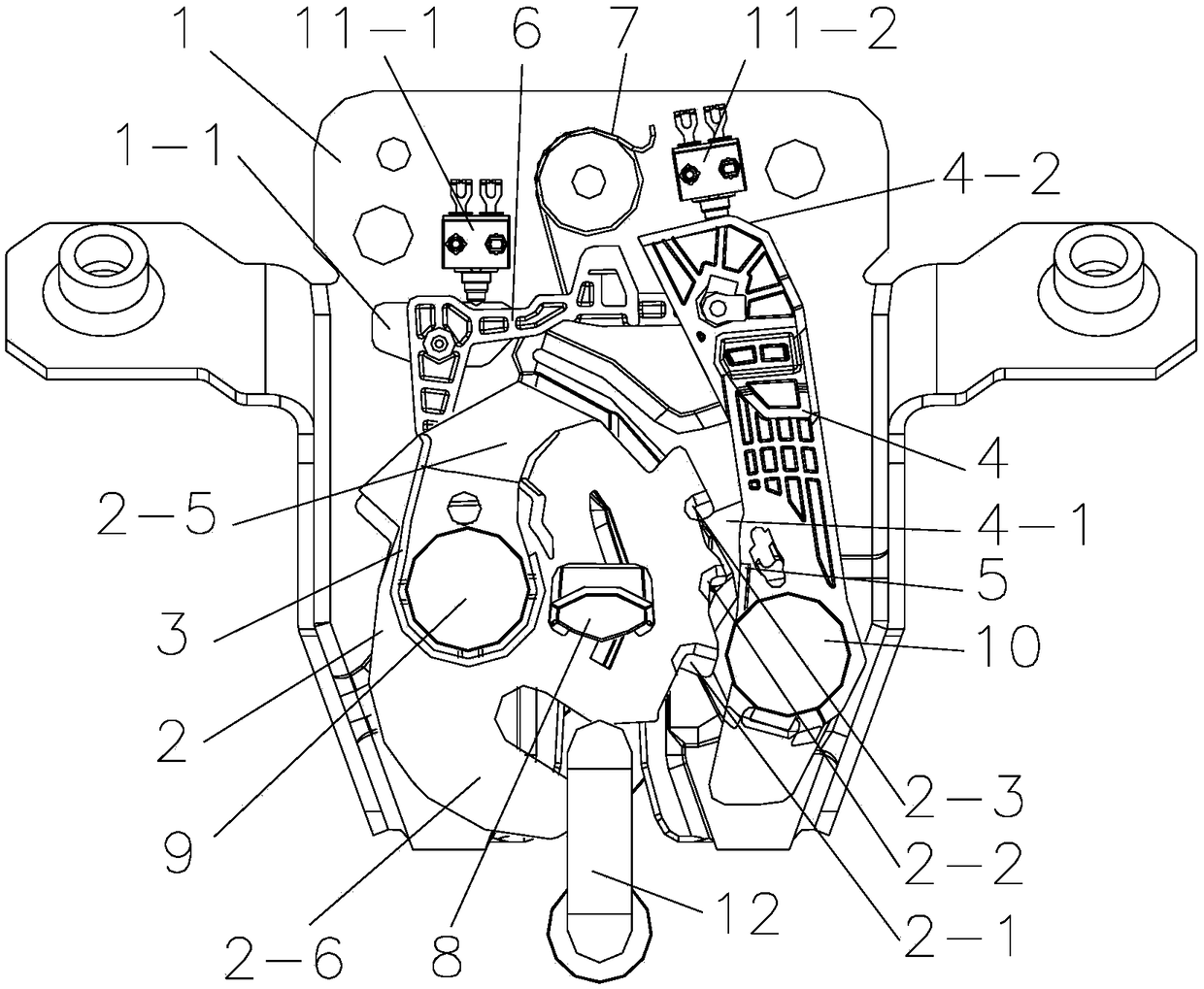

[0026] Such as Figure 1~6 As shown, an electric suction lock mechanism with a three-stage locking position includes a base plate 1 and a lock hook and pawl system arranged on the base plate 1. The base plate 1 is provided with a housing (shown in the figure), so The shell is used to cover the lock hook pawl system, the lock hook pawl system includes the lock hook 2, the lock hook elastic element 3, the pawl 4, the ratchet elastic element 5 and the detection device, the lock hook 2 and the ratchet The claws 4 are all rotatably arranged on the bottom plate 1, and the lock hook 2 is provided with three lock positions in sequence along its rotation direction, which are respectively the first-level lock position 2-1, the second-level lock position 2-2 and the third-level lock position 2- 3. There is a protrusion 4-1 extending outward on the pawl 4 that matches the locking position. When the lock hook 2 is rotated and locked, the protrusion 4-1 slides through the three-level lockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com