Unidirection control combined power adjustable air inlet way and design method thereof

A combined power and air inlet technology, applied in design optimization/simulation, calculation, mechanical equipment, etc., can solve the problems of unfavorable air inlet performance improvement, difficult design of adjustment mechanism, short design cycle, etc., to reduce design difficulty, The effect of widening the working range and improving aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings. The following embodiments are only used to explain the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

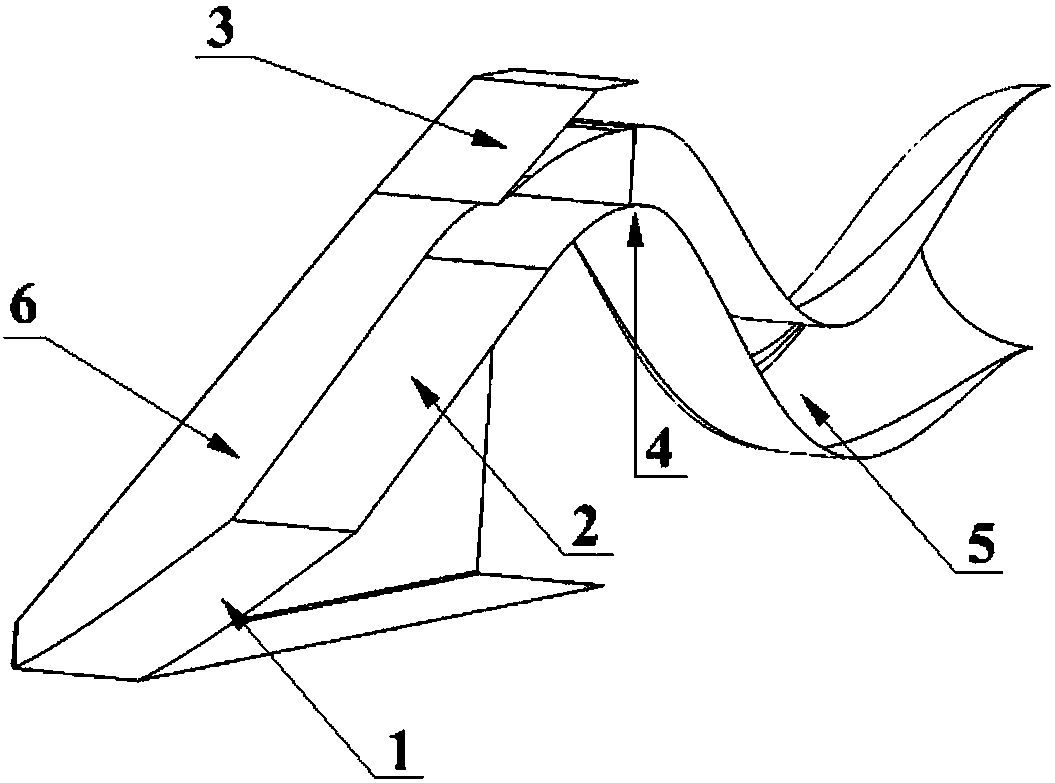

[0024] The current supersonic intake port requires the aircraft to work in a wide speed range and requires high intake port performance at each Mach number. Conventional fixed geometry intake ports are often difficult to achieve, and low Mach number starting restricts it. An important factor of development, therefore, the design of variable geometry inlet and model design with high engineering realizability has gradually become a research hotspot.

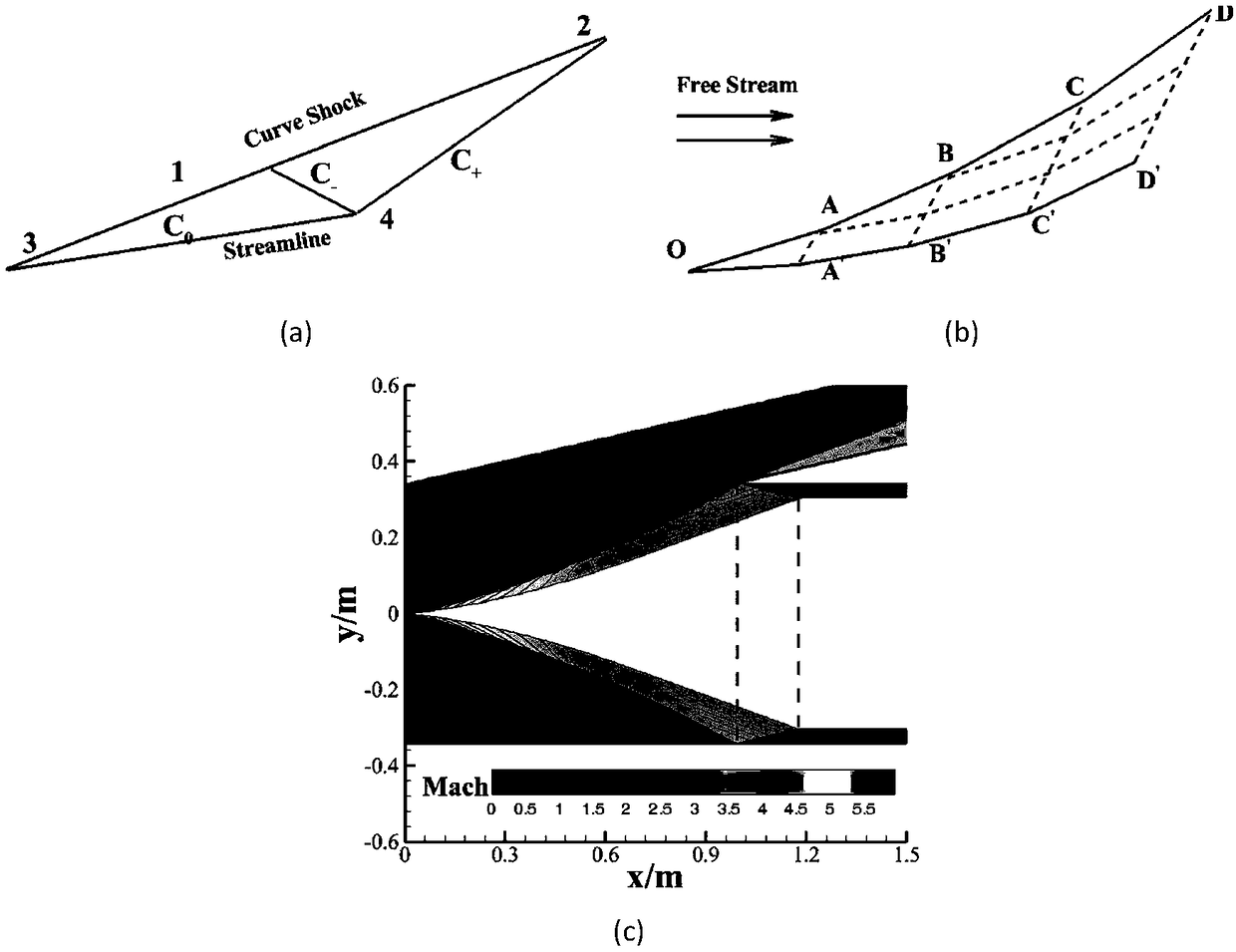

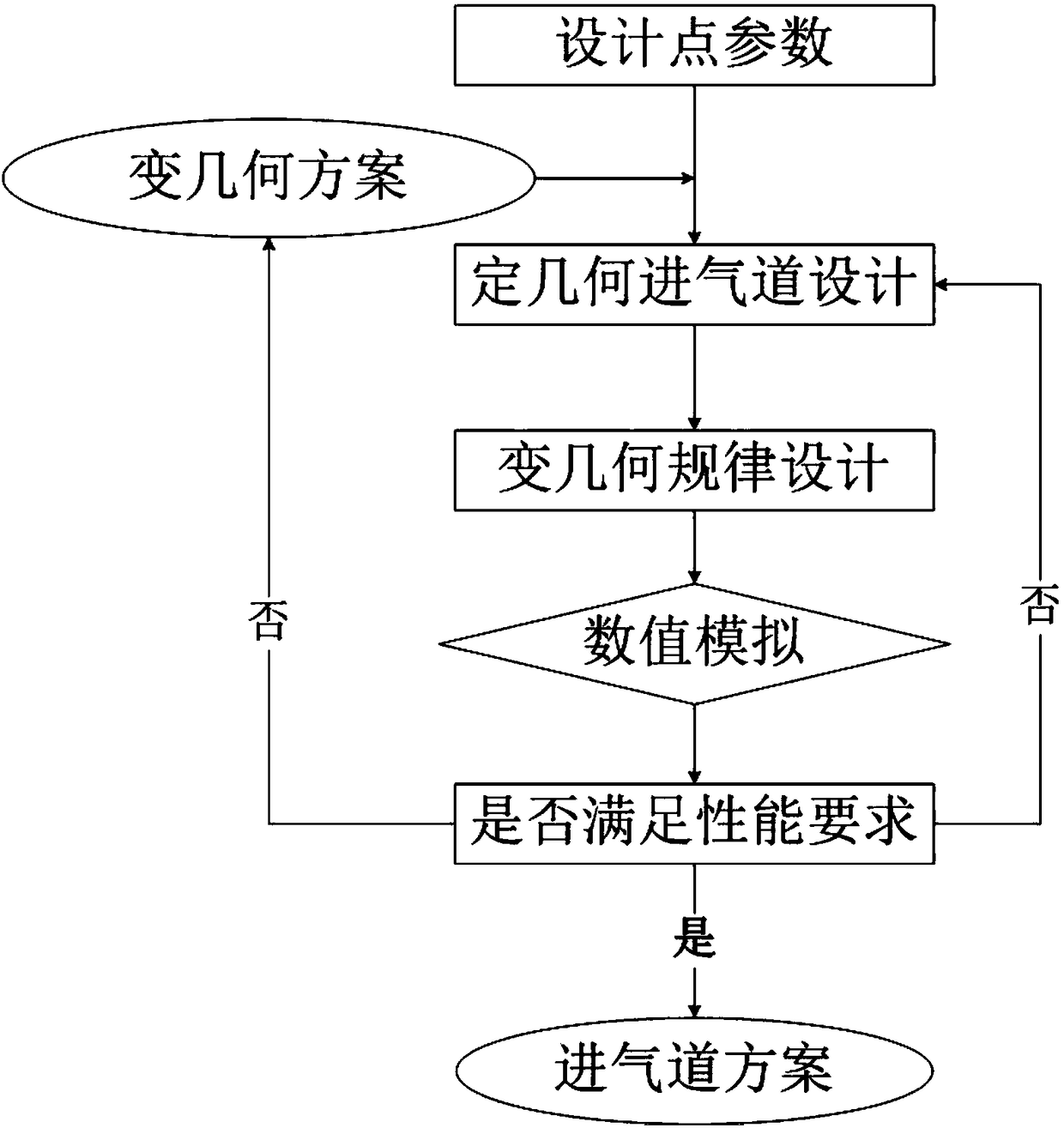

[0025] Based on this background, the present invention proposes a "curved surface + wedge surface" two-stage compression variable geometry inlet design method, in which the curved surface compression part mainly adopts the characteristic line method, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com