Heavy-oil aero-engine and aircraft

A technology of aero-engine and heavy oil, applied in engine components, machines/engines, and bringing fuel into the engine through high-pressure gas. and other problems, to achieve the effect of smooth drainage, reducing the risk of knocking, and improving the impact effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

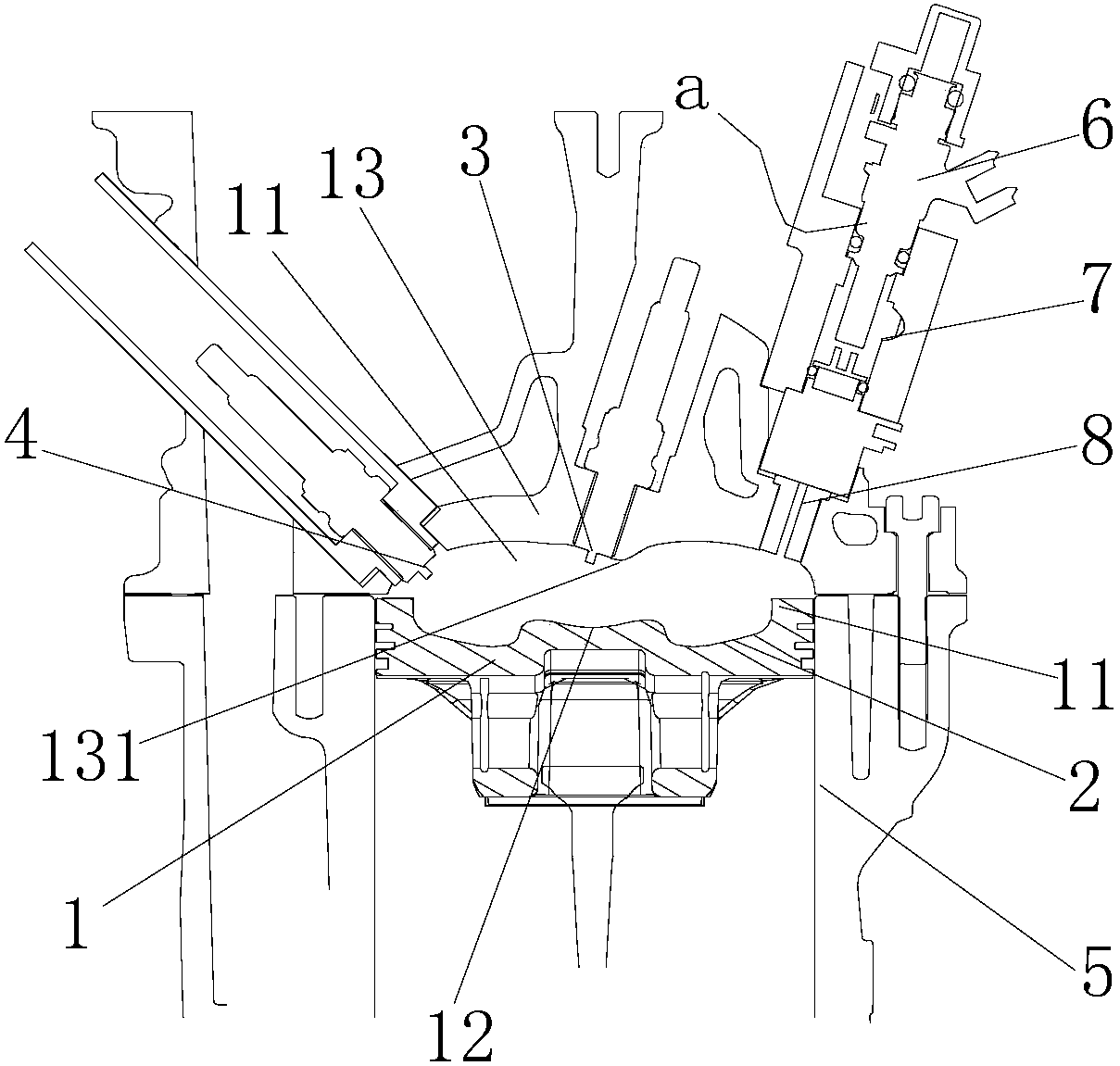

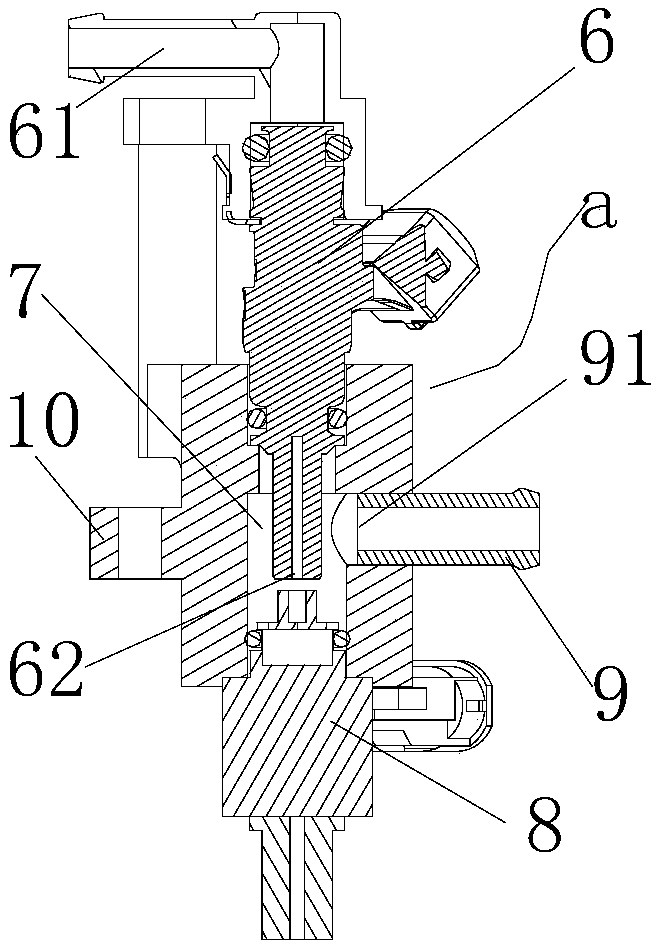

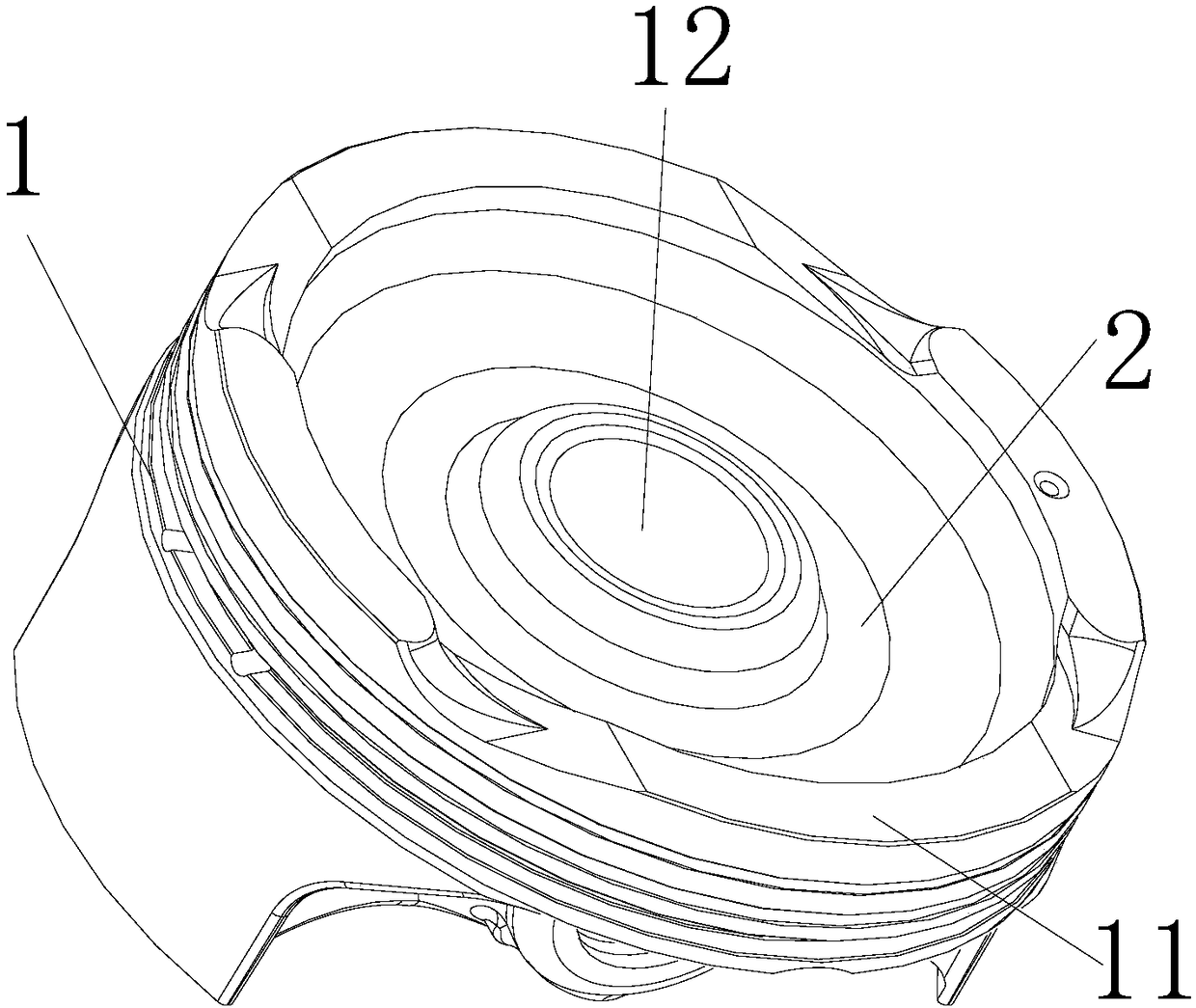

[0022] As shown in the figure: the heavy oil aircraft engine of the present embodiment includes a cylinder block 5, a cylinder head 13 and a piston assembly. As shown in the figure, the piston of the piston assembly is located in the cylinder block 1, and the cylinder head 13 is provided with a The fuel injection assembly that is sprayed into the combustion chamber 11; the top surface of the piston is provided with an annular guide portion that is annularly sunken along the circumferential direction (concentric with the piston top surface), and the annular guide portion corresponds to the injection direction of the fuel injection assembly (referring to When the fuel assembly is injected, and the position of the piston makes the outer surface of the annular guide part correspond to the injection direction), the center of the annular guide part (generally also the center of the top surface of the piston) forms a guide protrusion 12, and the guide protrusion 12 is due to the The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com