Four-stage type hydraulic machine stepless transmission device used for caterpillars

A hydraulic mechanical and stepless transmission technology, which is applied in the direction of transmission devices, fluid transmission devices, mechanical equipment, etc., can solve the problem of drastic changes in engine load, affecting the life and reliability of shifting control components and related mechanical structures of the whole machine, and the transmission system Problems such as unsatisfactory transmission efficiency, to achieve the effect of improving power and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

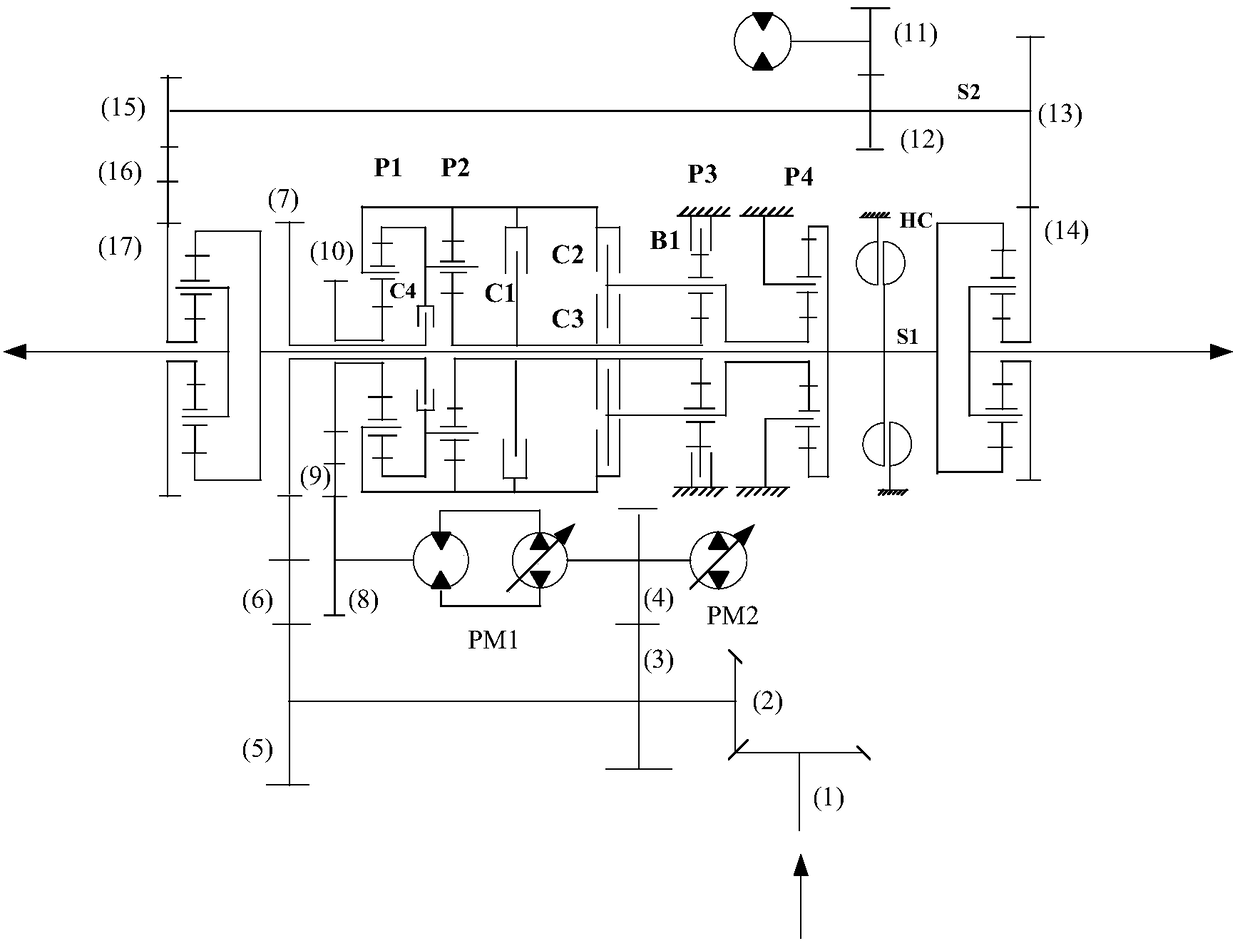

[0023] In this embodiment, the four-stage hydraulic-mechanical continuous stepless transmission device is applied to the tracked vehicle, such as figure 1As shown in the schematic diagram of the connection relationship of each component, the device includes: a planetary coupling mechanism, a hydraulic speed regulating component, a section shifting control component, a hydraulic stepless steering component, and a hydraulic deceleration component; wherein, the planetary coupling mechanism includes: the first planetary row P1, The second planetary row P2, the third planetary row P3, and the fourth planetary row P4; the hydraulic speed regulation components include the first hydraulic speed regulation circuit PM1 composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com