Lubrication oil supply protection device for gear transmission mechanism

A technology of gear transmission mechanism and protection device, which is applied in the directions of transmission parts, engine lubrication, gear lubrication/cooling, etc., can solve the problems of mechanism bearing and gear pair lubrication, cannot provide lubricating oil, etc., to avoid wear or damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

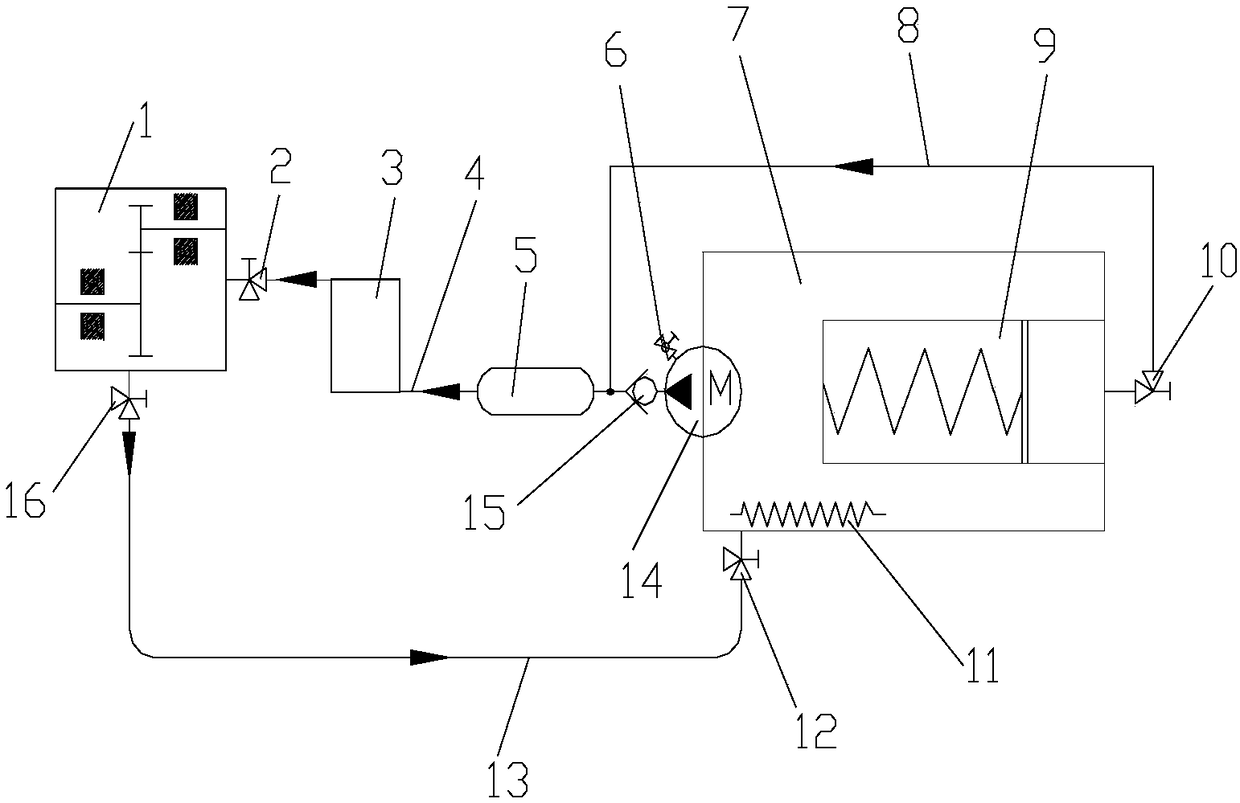

Embodiment 1

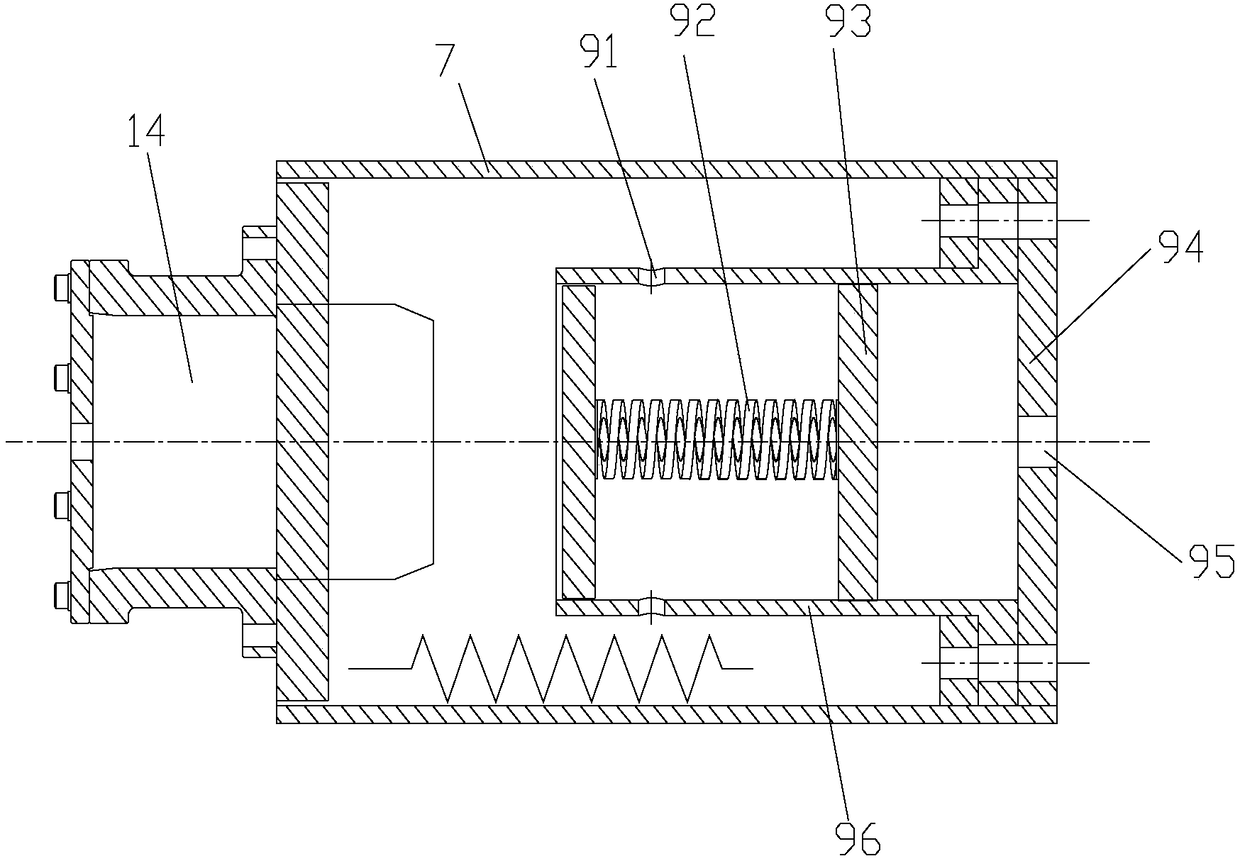

[0021] The oil tank 7 is placed horizontally in a cylindrical shape, and an oil pump 14 is installed on the left end surface of the oil tank 7, and the oil pump 14 is equipped with a pressure regulating valve 6 for regulating the pressure of the pipeline. An oil heater 11 (Taiyi Thermal Electric Appliance Company-QY380-PT1-3023) for heating lubricating oil is installed on the bottom of the inner cavity of the oil tank 7, and a pressure oil storage chamber coaxial with the oil tank 7 is installed on the right end surface of the oil tank 7 9. The pressure oil storage chamber 9 includes a barrel-shaped chamber 96, a piston 93 arranged in the chamber 96, a spring 92 fixed at the bottom of the chamber 96 and the piston 93 at both ends, and an end arranged at the port of the chamber 96. The cover 94 and the end cover 94 are provided with an oil outlet 95 . The outlet of the oil pump 7 (Chongqing Yimei Machinery Complete Equipment Co., Ltd.-LSQYB60-80) is connected to the lubricatin...

Embodiment 2

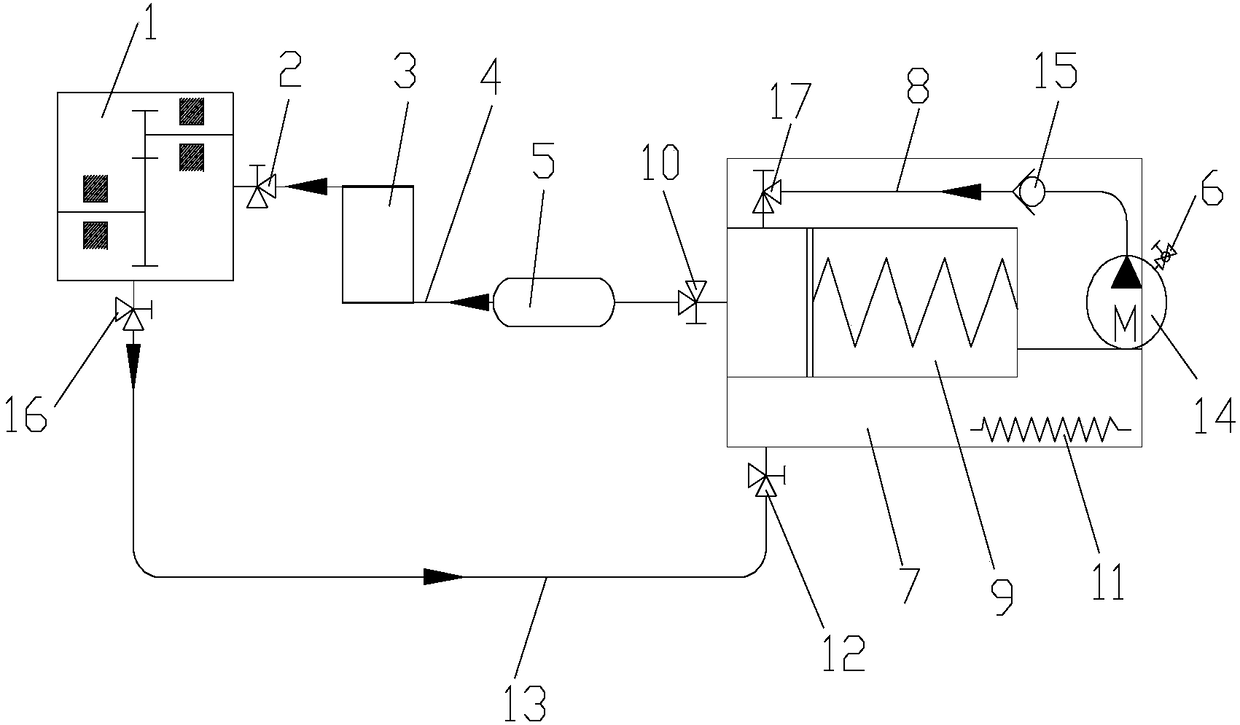

[0024] On the basis of Example 1, such as figure 2 As shown, the bypass oil supply circuit 8 is set in the oil tank 7, the outlet of the oil pump 14 is connected to the bypass oil pipeline 8, the other end of the bypass oil pipeline 8 passes through the fifth regulating valve 17 and the pressure oil storage chamber 9, and the bypass oil pipeline 8 A one-way valve 15 is provided, and the oil outlet 95 of the pressure oil storage chamber 9 is connected with the main oil supply circuit 4 through the third regulating valve 10 .

[0025] When the gear transmission mechanism operates normally, the oil pump 14 works normally, the first regulating valve 2, the second regulating valve 10, the third regulating valve 16, the fourth regulating valve 12, and the fifth regulating valve 17 are all opened, and the oil pump 14 continues to run. The oil supply pressure is adjusted through the pressure regulating valve 6, the fifth regulating valve 17, the third regulating valve 10, and the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com