A transport system for silicon carbide crystal growth

A technology of crystal growth and conveying system, which is applied in the field of conveying system, can solve the problems of being stuck, unable to crush lumpy materials into powdery materials, etc., and achieve the effect of solving the effect of co-solvent inclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

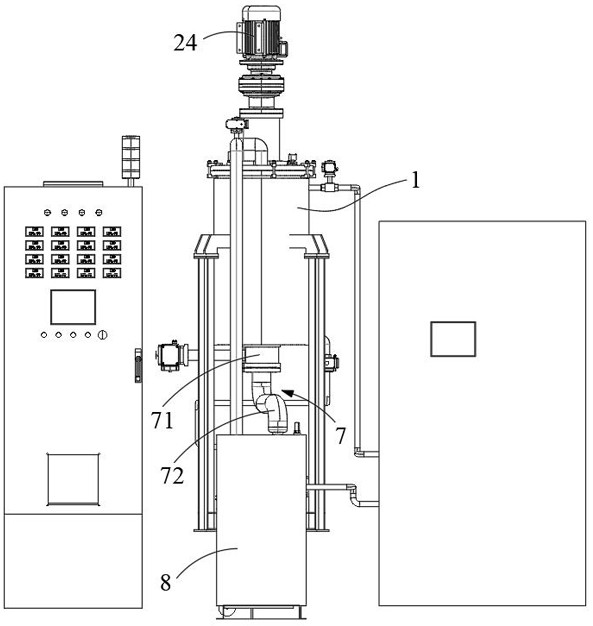

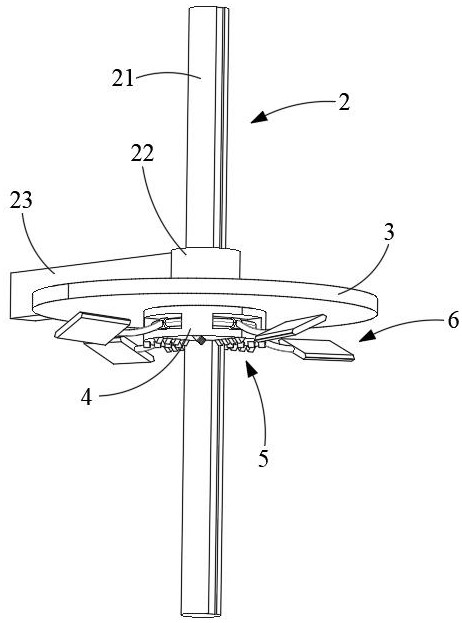

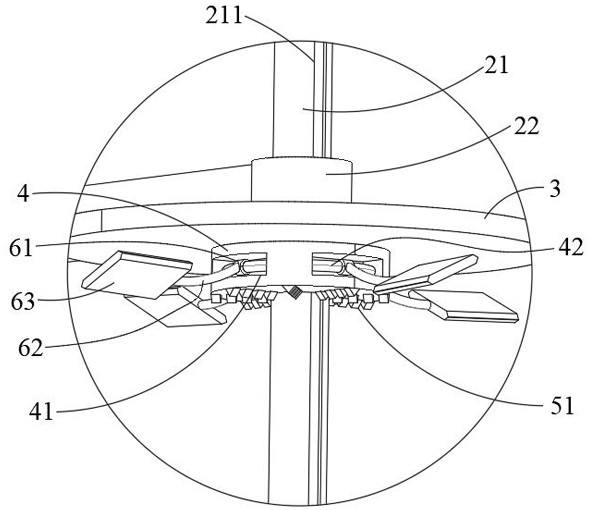

[0036] In this example, if Figure 1 to Figure 5 As shown, this embodiment provides a transport system for silicon carbide crystal growth, which includes: a first reaction kettle 1, a screw mechanism 2, a movable plate 3, a mounting plate 4, a crushing mechanism 5, a stirring mechanism 6 and a conveying mechanism 7; Wherein the first reaction kettle 1 is provided with a storage cavity for storing materials; the screw mechanism 2 is longitudinally arranged in the first reaction kettle 1, and the movable plate 3 is movably connected to the screw mechanism 2 Above, the installation disk 4 is fixed on the bottom of the movable disk 3, the crushing mechanism 5 is fixed on the bottom of the installation disk 4, and the stirring mechanism 6 is movably arranged on the circumferential direction of the installation disk 4; the screw mechanism 2 drives The movable disk 3 moves longitudinally, and the movable disk 3 rotates on the screw mechanism 2 during the longitudinal movement, that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com