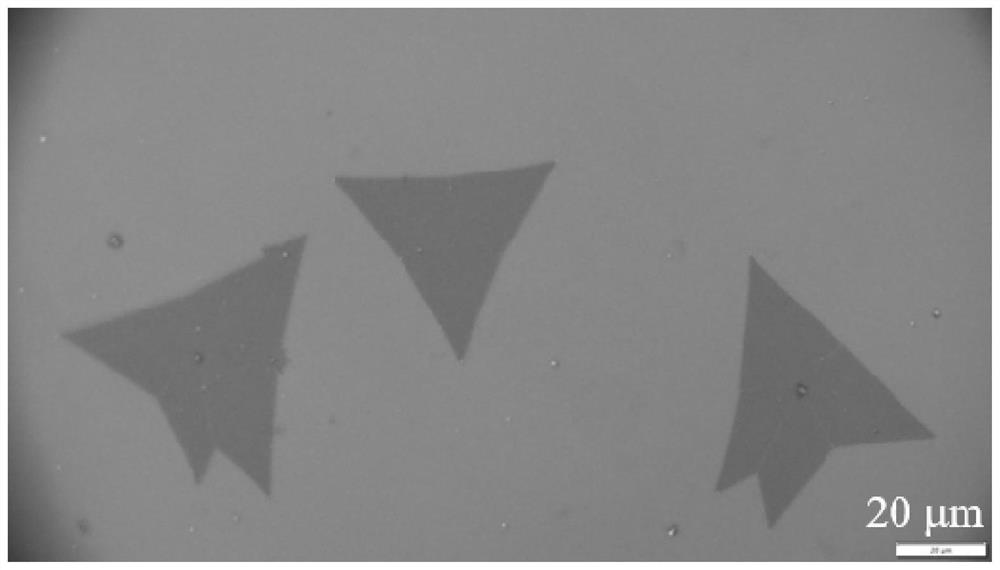

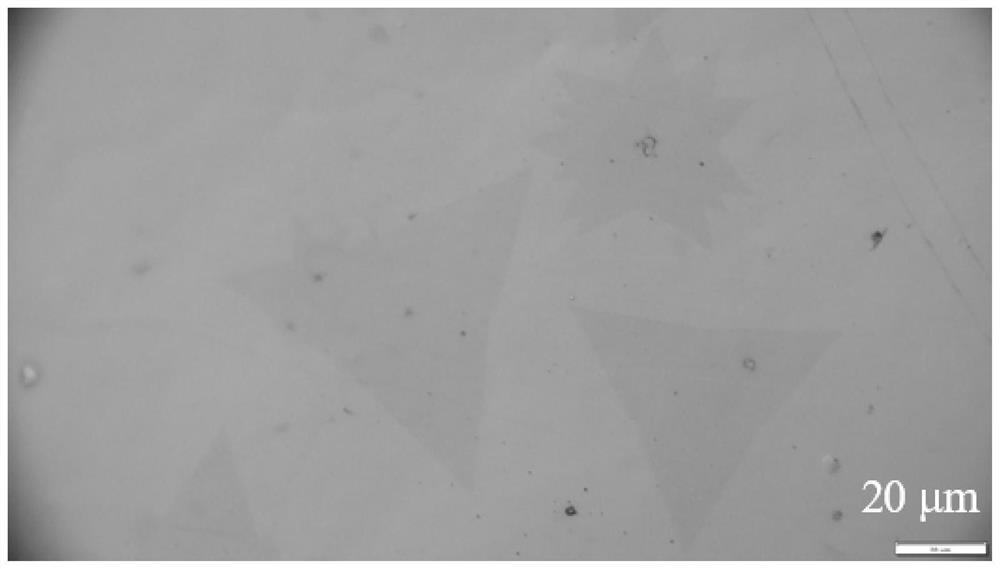

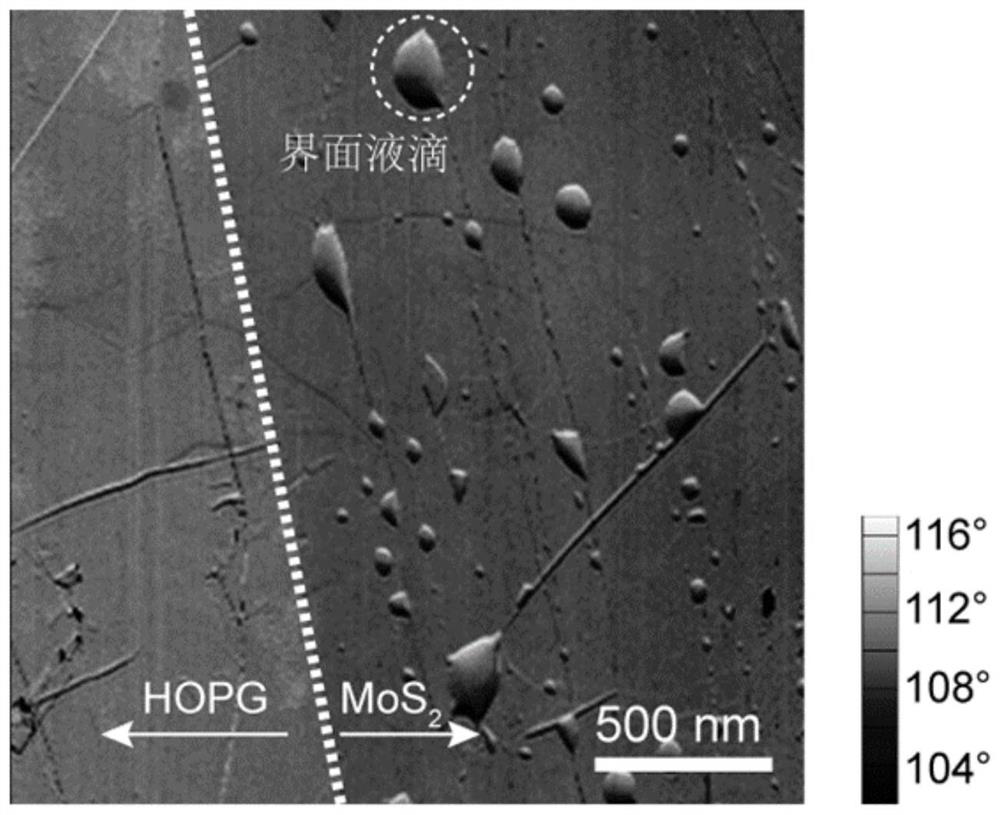

Method for adjusting friction force of molybdenum disulfide by constructing interface liquid drops

A technology of molybdenum disulfide and single-layer molybdenum disulfide, which is applied in the field of nano-material lubrication, can solve the problems of difficult control of characteristics and increased friction, and achieve the effect of reducing friction, enhancing lubrication performance, and surface cleaning without wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for constructing interfacial liquid droplets to regulate molybdenum disulfide friction, the steps are as follows:

[0045] (1) Coating: the anisole solution (mass concentration of 10 microliters of polymethyl methacrylate (PMMA) is 4.5%, PMMA relative molecular mass 950K) is evenly spin-coated on the growth there is monolayer molybdenum disulfide The molybdenum disulfide surface of a silicon wafer (0.5cm×0.5cm) was spin-coated at 500rpm for 10 seconds, and then spin-coated at 2000rpm for one and a half minutes. Then anneal in air at 90° C. for 3 minutes to solidify the PMMA to obtain a PMMA / molybdenum disulfide / silicon wafer.

[0046] (2) Etching: immerse the PMMA / molybdenum disulfide / silicon wafer in 3mol / L KOH aqueous solution for etching, and the etching temperature is 160°C. After the etching is completed, the PMMA film with molybdenum disulfide will be separated from the silicon wafer, and the separated PMMA film will be placed in a 3mol / L KOH aqueous sol...

Embodiment 2

[0053] A method for constructing interfacial liquid droplets to regulate molybdenum disulfide friction, the steps are as follows:

[0054] (1) Coating: the anisole solution (mass concentration is 4.5%, PMMA relative molecular mass 950K) of 20 microliters of polymethyl methacrylate (PMMA) is evenly spin-coated on the growth there is monolayer molybdenum disulfide The molybdenum disulfide surface of a silicon wafer (1 cm×1 cm) was spin-coated at 500 rpm for 10 seconds, and then spin-coated at 2000 rpm for one and a half minutes. Then anneal in air at 90° C. for 3 minutes to solidify the PMMA to obtain a PMMA / molybdenum disulfide / silicon wafer.

[0055] (2) Etching: immerse the PMMA / molybdenum disulfide / silicon wafer in 4mol / L NaOH aqueous solution for etching, and the etching temperature is 160°C. After the etching is completed, the PMMA film with molybdenum disulfide will be separated from the silicon wafer, and the separated PMMA film will be placed in a 4mol / L NaOH aqueous s...

Embodiment 3

[0059] A method for constructing interfacial liquid droplets to regulate molybdenum disulfide friction, the steps are as follows:

[0060] (1) Coating: the anisole solution (mass concentration is 4.5%, PMMA relative molecular mass 950K) of 20 microliters of polymethyl methacrylate (PMMA) is evenly spin-coated on the growth there is monolayer molybdenum disulfide The molybdenum disulfide surface of a silicon wafer (1 cm×1 cm) was spin-coated at 500 rpm for 10 seconds, and then spin-coated at 2000 rpm for one and a half minutes. Then anneal in air at 90° C. for 3 minutes to solidify the PMMA to obtain a PMMA / molybdenum disulfide / silicon wafer.

[0061] (2) Etching: immerse the PMMA / molybdenum disulfide / silicon wafer in 3mol / L KOH aqueous solution for etching, and the etching temperature is 160°C. After the etching is completed, the PMMA film with molybdenum disulfide will be separated from the silicon wafer, and the separated PMMA film will be placed in a 3mol / L KOH aqueous sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com