A design method for the spool of a multi-section mixing regulating valve

A technology of mixed adjustment and design method, applied in the direction of lift valve, valve device, mechanical equipment, etc., can solve the problems that are not conducive to improving the energy utilization rate of the downstream turbine exhaust gas of the two-stage supercharging system, reducing the energy utilization rate of the downstream turbine, and the adjustment characteristics are not good. Good and other problems, to achieve the effect of improving exhaust gas energy utilization, less vortex, and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

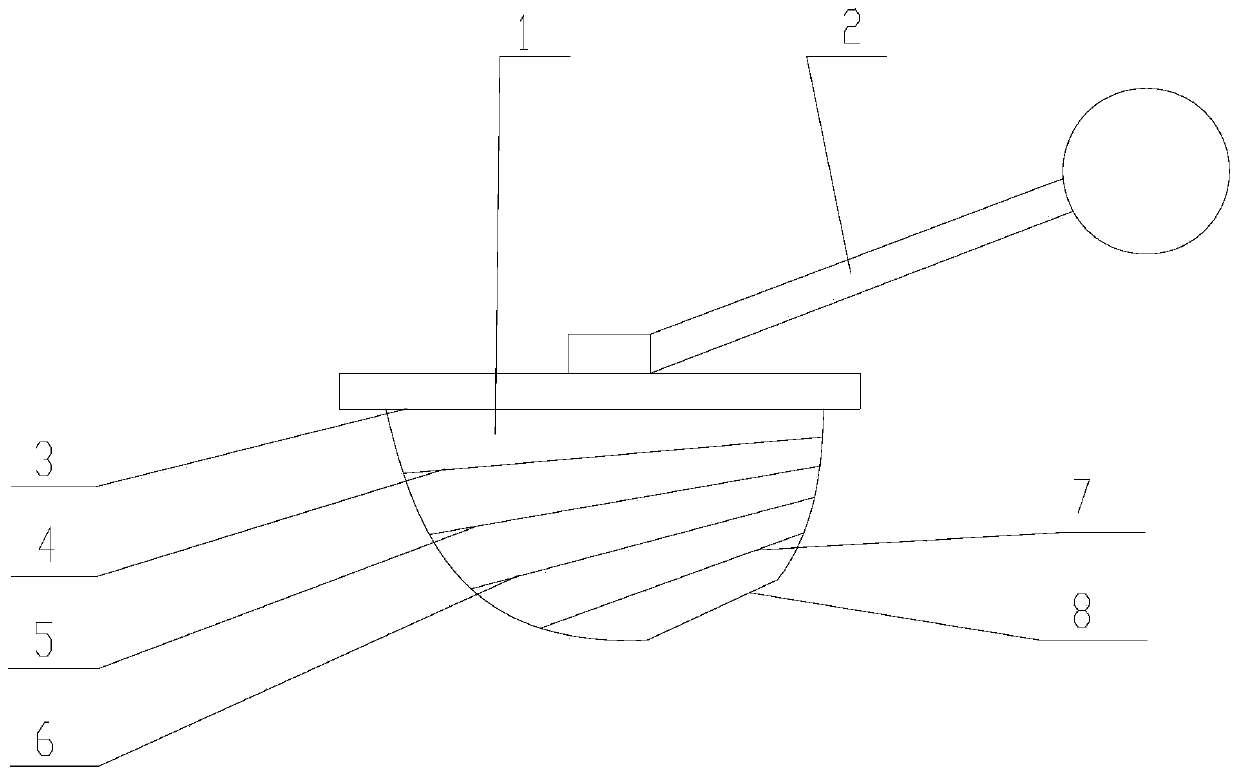

[0026] The present invention will be described in detail below with reference to the accompanying drawings and examples.

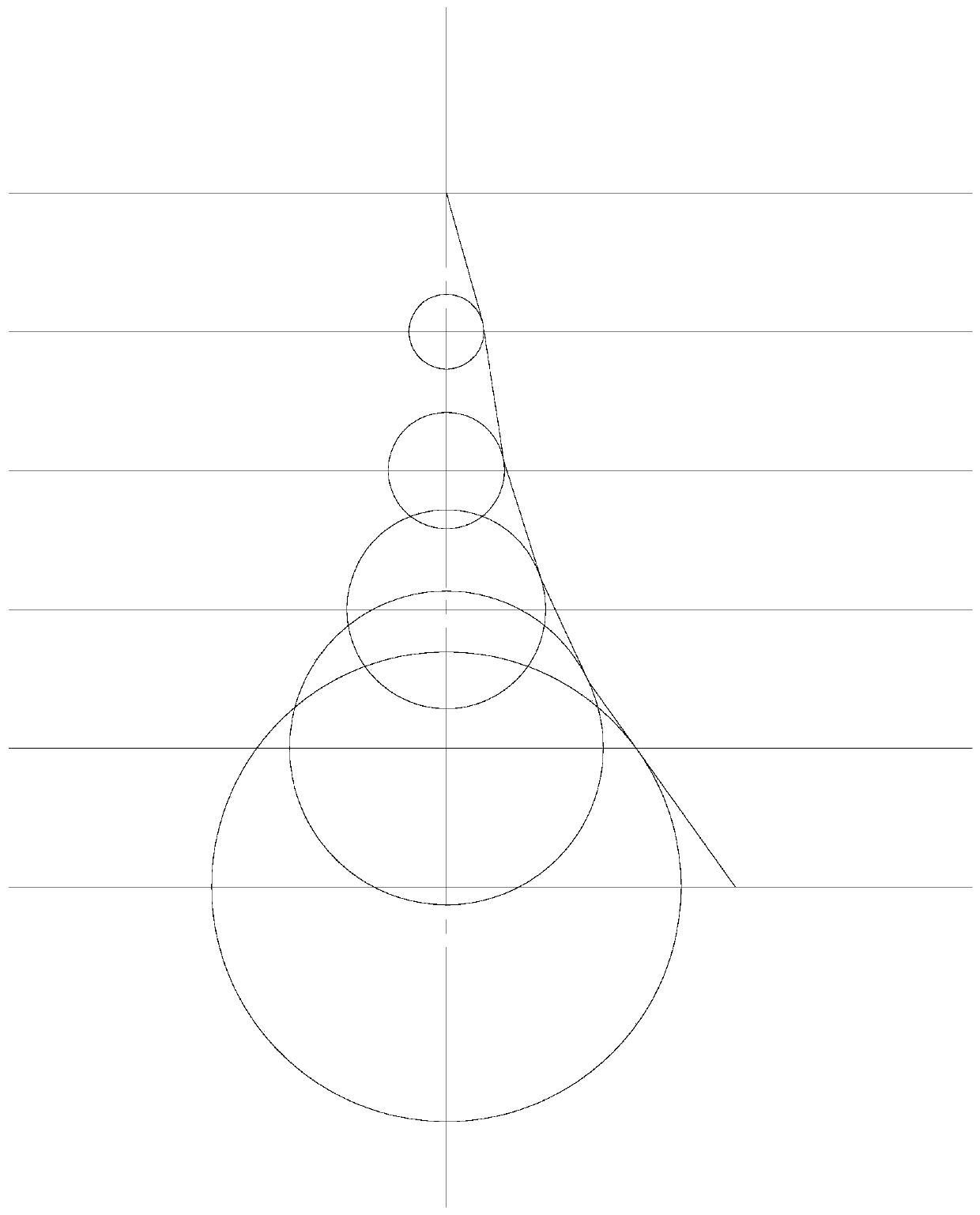

[0027] The method for designing the spool of the multi-section mixing control valve according to the embodiment of the present invention includes the following steps:

[0028] 1) The flow formula of the ideal equal percentage flow characteristic is as follows:

[0029]

[0030] In the formula, Q is the actual flow through the valve, Qmax is the maximum flow of the valve, l is the actual stroke of the valve, L is the maximum stroke of the valve, R is the adjustable ratio, and the adjustable ratio R is defined as the maximum flow that the valve can control Ratio to the minimum controllable flow.

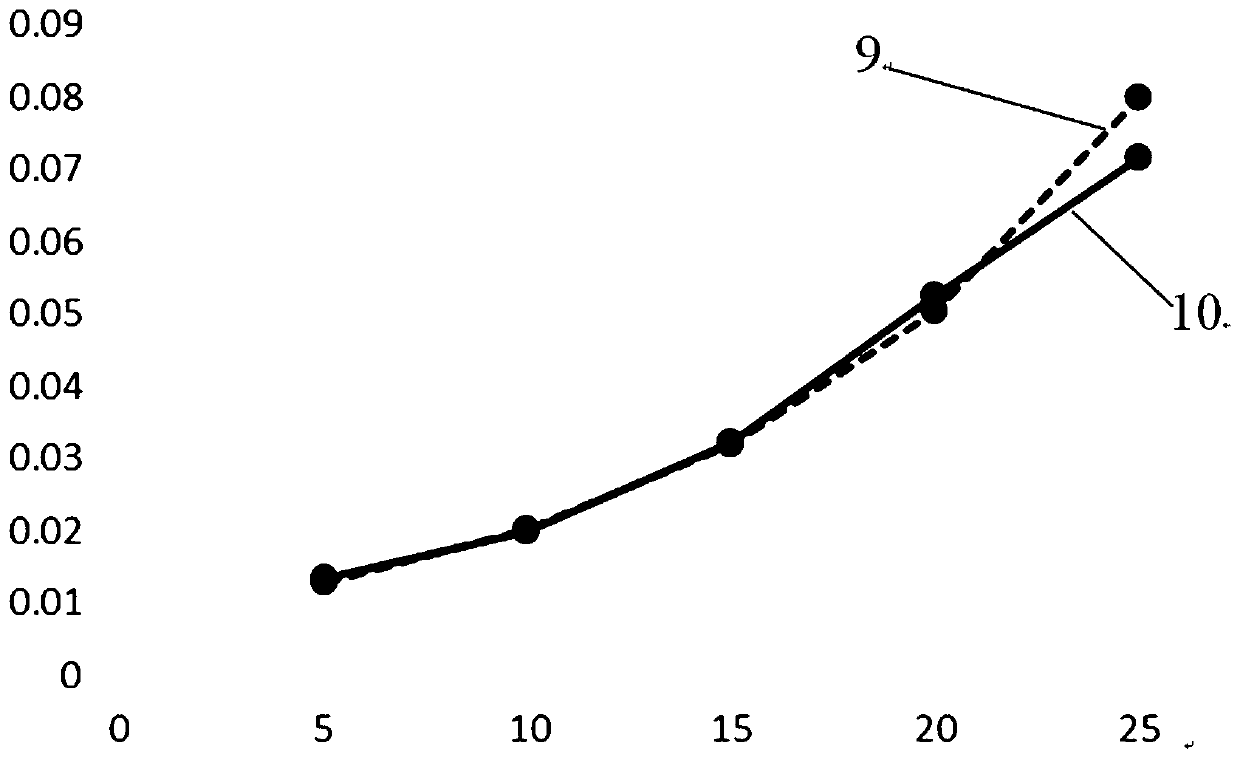

[0031] In this embodiment, the valve diameter is 25mm as an example, and the adjustable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com