Electric heating steel pipe composite thermal insulation plastic pipe device

A technology of composite thermal insulation and electric heating steel pipes, which is applied in the directions of pipes/pipe joints/fittings, pipe heating/cooling, mechanical equipment, etc. The effect of large strength improvement and mature and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

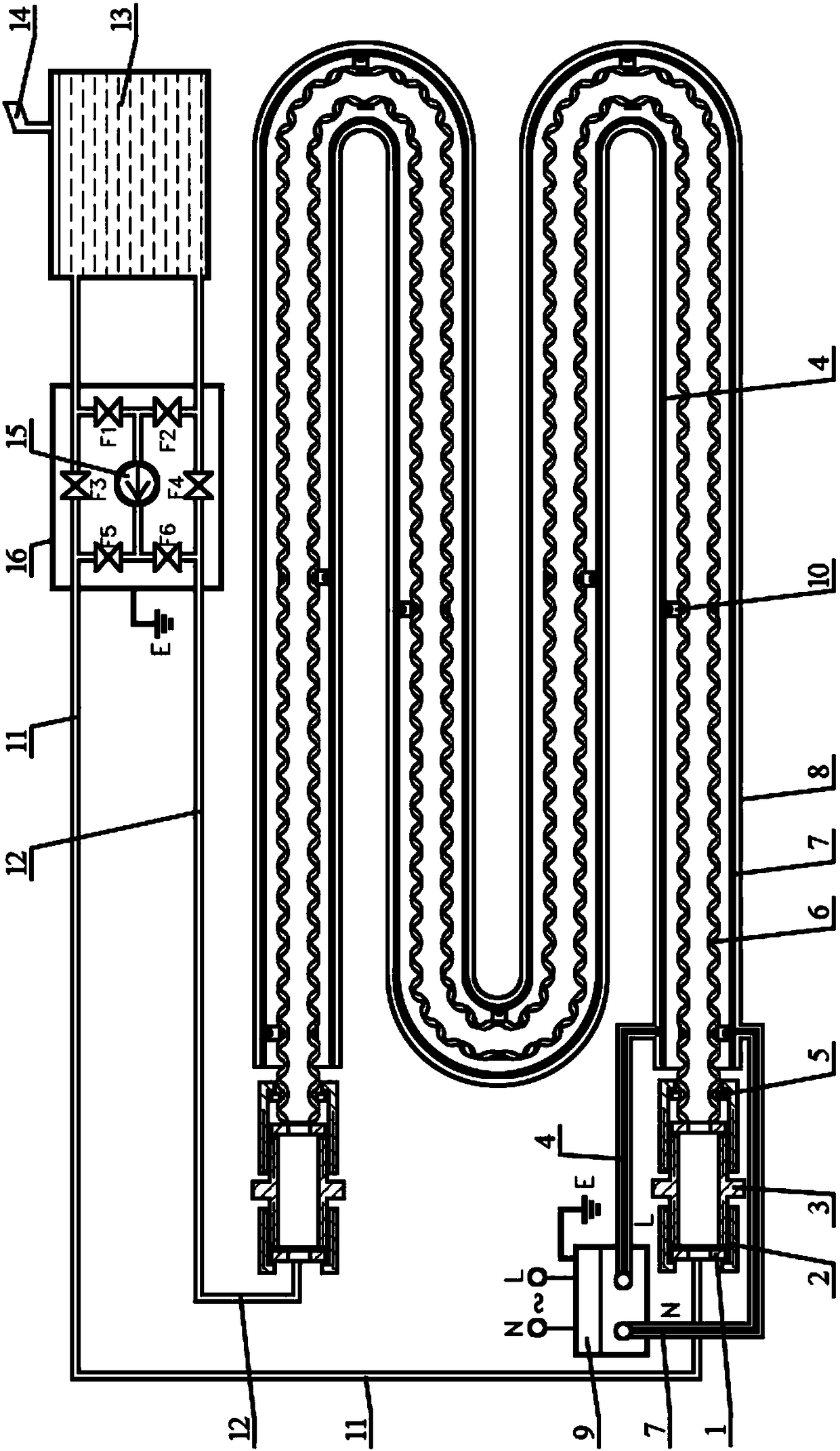

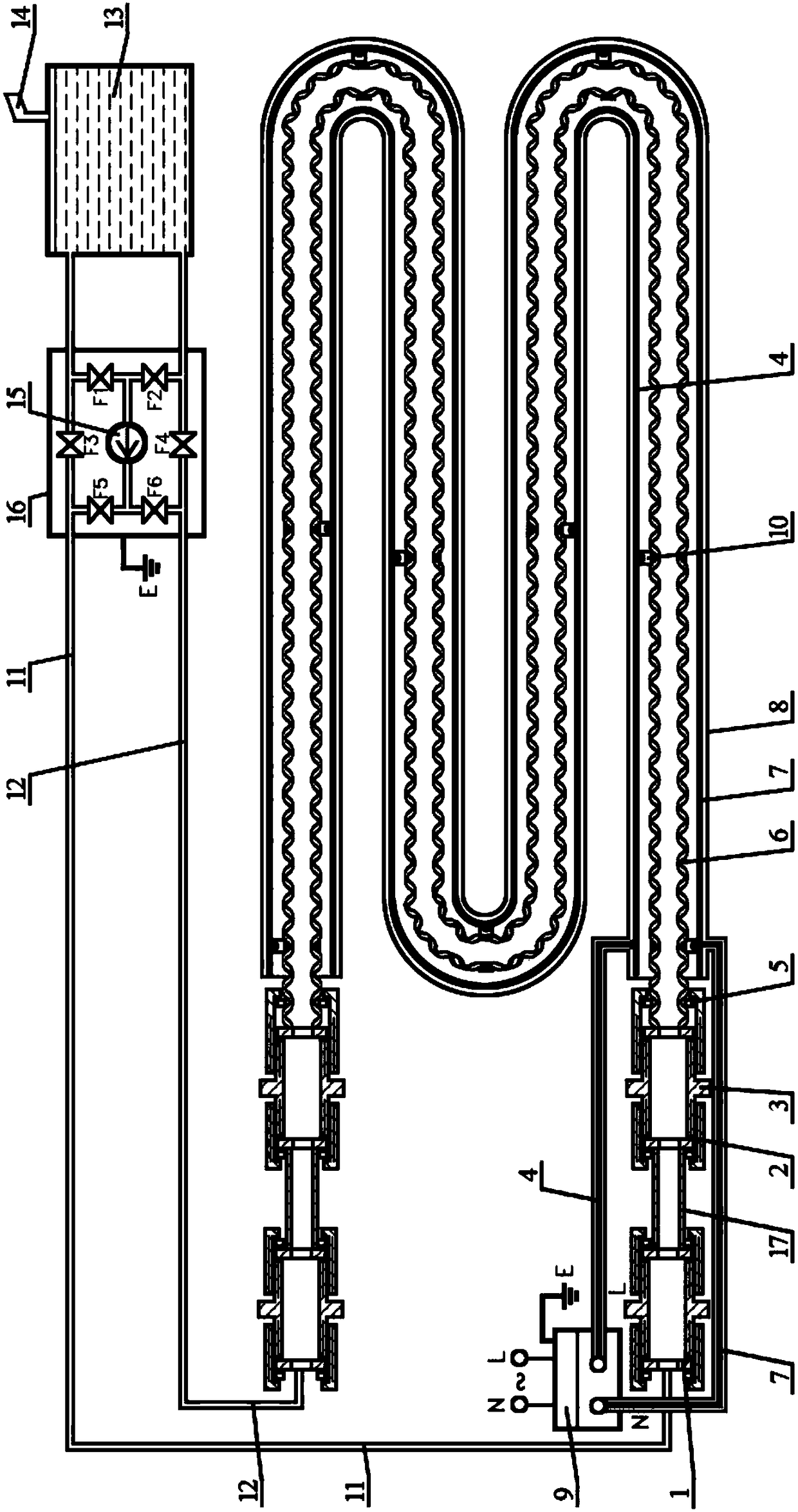

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

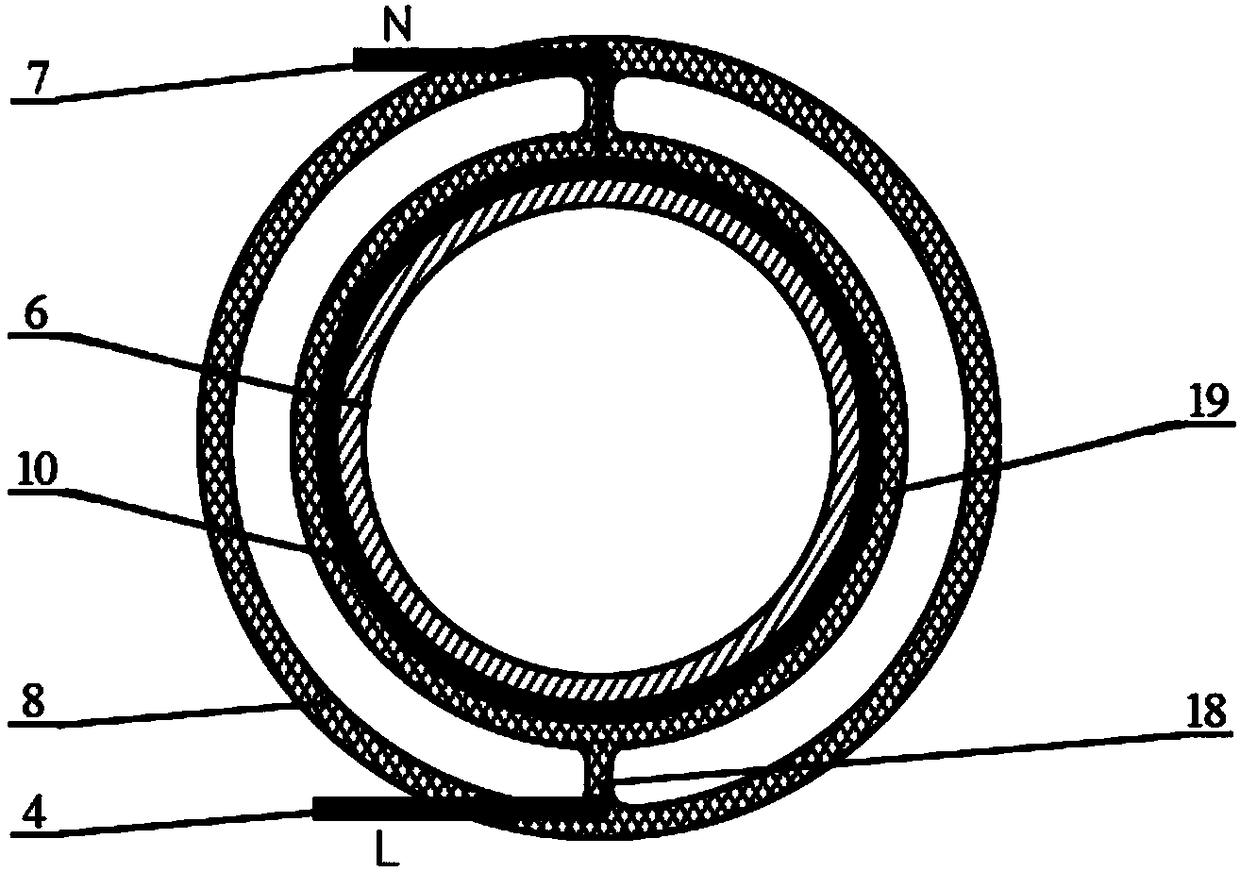

[0026] exist figure 1 , image 3 , Figure 4 In the first embodiment shown: an electric heating steel pipe composite thermal insulation plastic pipe device, including: sealing gasket 1, transition seal connection pipe fitting nut 2, transition seal connection pipe fitting pair wire 3, fire wire 4, transition seal connection pipe fitting positioning card Ring 5, steel pipe 6, zero line 7, external electrical insulating sleeve 8, intelligent temperature control power supply 9, electric connection hoop lead-out electrode 10, heating water supply pipe 11, heating return water pipe 12, energy storage water tank 13, intake and exhaust Pipe 14, circulating water pump 15, water distributor 16, electrical insulation pipe 17, support ribs 18, inner electrical insulation sleeve 19.

[0027] Steel pipe 6 includes conventional carbon steel pipe, corrugated carbon s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com