Rapid pipeline corrosion defect repairing method and safety emergency tool box

A repair method and toolbox technology, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, machinery and equipment, etc., can solve problems such as the inability of repair techniques and tools, endangering the life safety of surrounding people, and leakage of flammable and explosive gases. , to achieve the effect of compact structure, reduced probability of occurrence and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

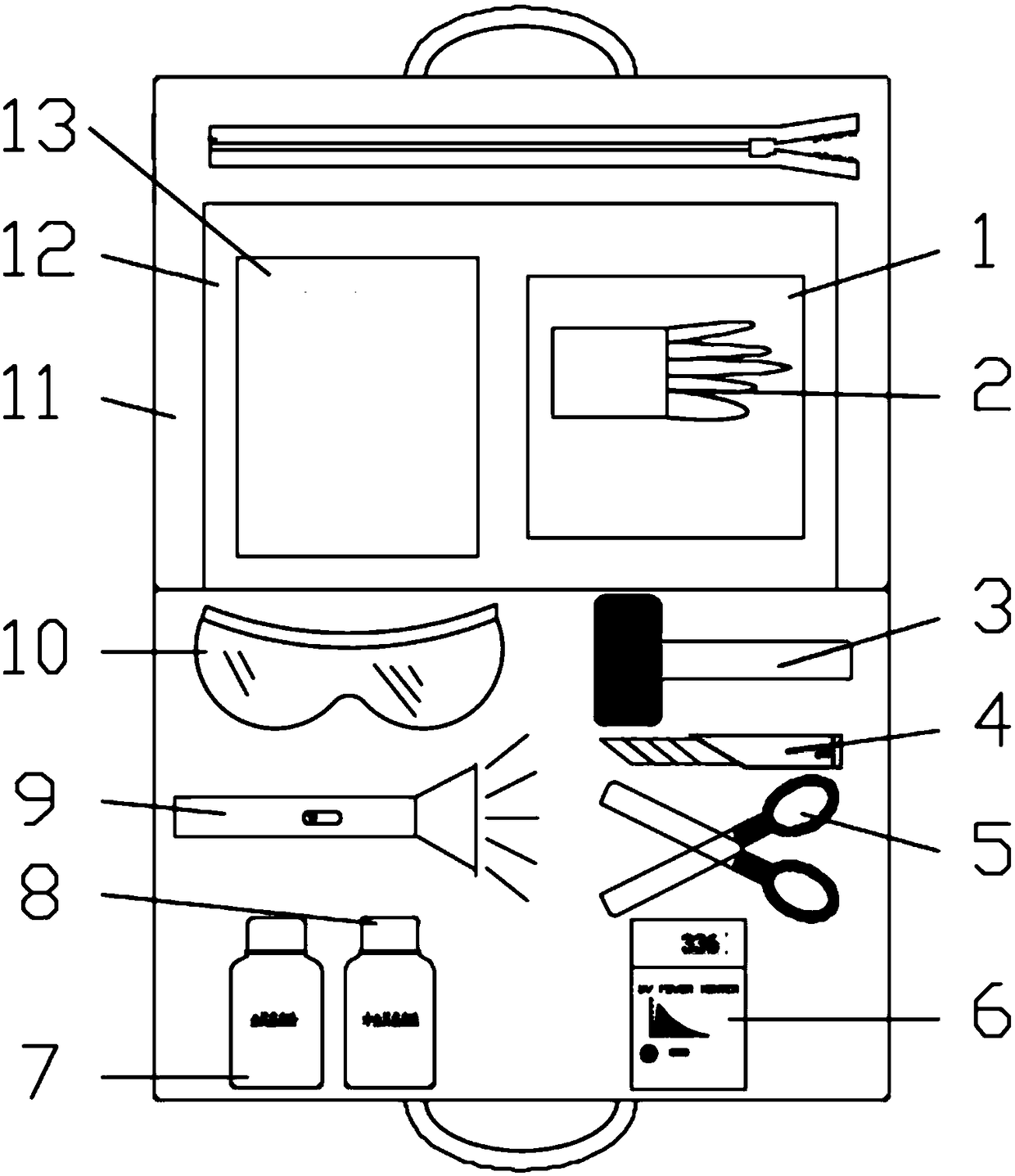

[0029] The technical solution adopted in the present invention: a method for quickly repairing pipeline corrosion defects, comprising the following steps:

[0030] Step 1. Surface cleaning: For metal pipelines with corrosion defects, use sandpaper to polish the surface of metal pipelines, and then use metal-based primer to coat the surface of metal pipelines; After dust, impurities, grease, etc. are cleaned up, use a non-metallic primer to coat the surface of the non-metallic pipeline;

[0031] Step 2, sheet winding: After the metal-based primer and non-metal-based primer are dry, first use a hood to cover the surface of the pipeline to be repaired; use scissors to cut the corresponding specifications of the glass fiber reinforced composite according to the area of the pipeline to be repaired Fiber sheet made of high-quality materials; tear off a little protective film on the surface of the fiber sheet, wind the pipeline, tear off the protective film while winding, until it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com