Organic waste treatment device and treatment technology

A technology of organic waste and treatment equipment, which is applied in the field of organic waste treatment equipment and treatment technology, can solve problems such as difficult removal of dioxin, and achieve the effects of improving waste treatment effects, reducing possibilities, and reducing treatment pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

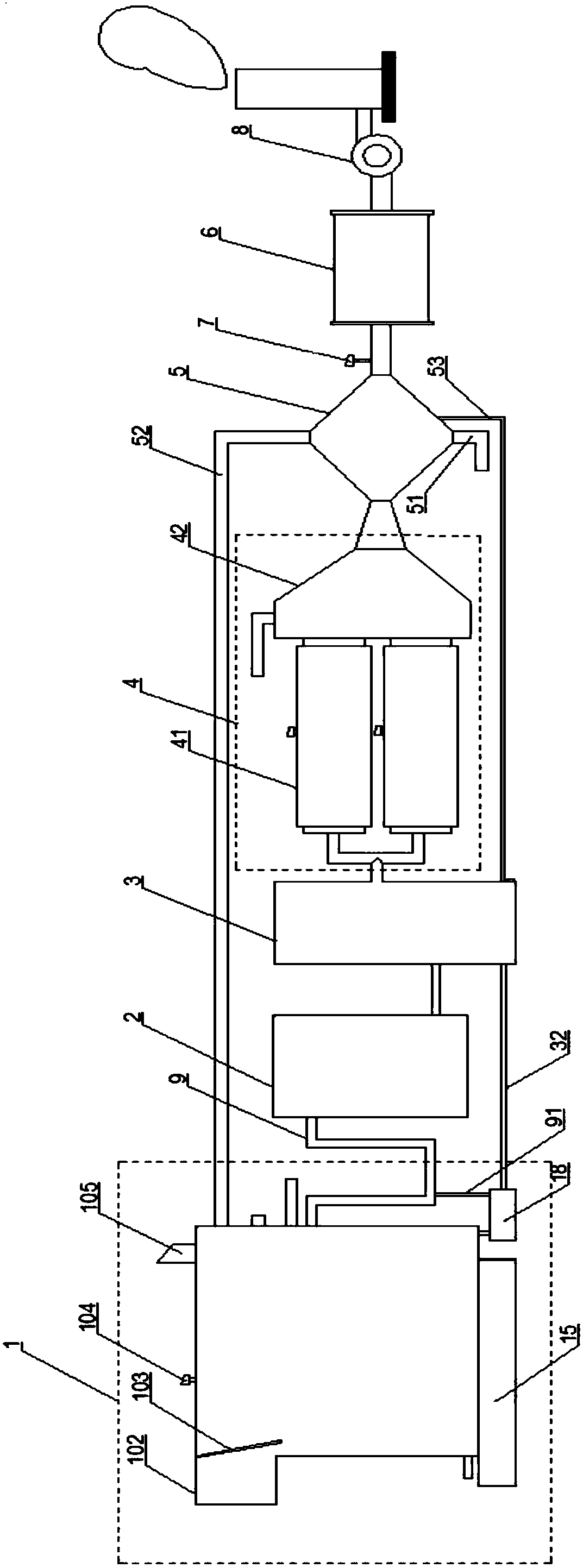

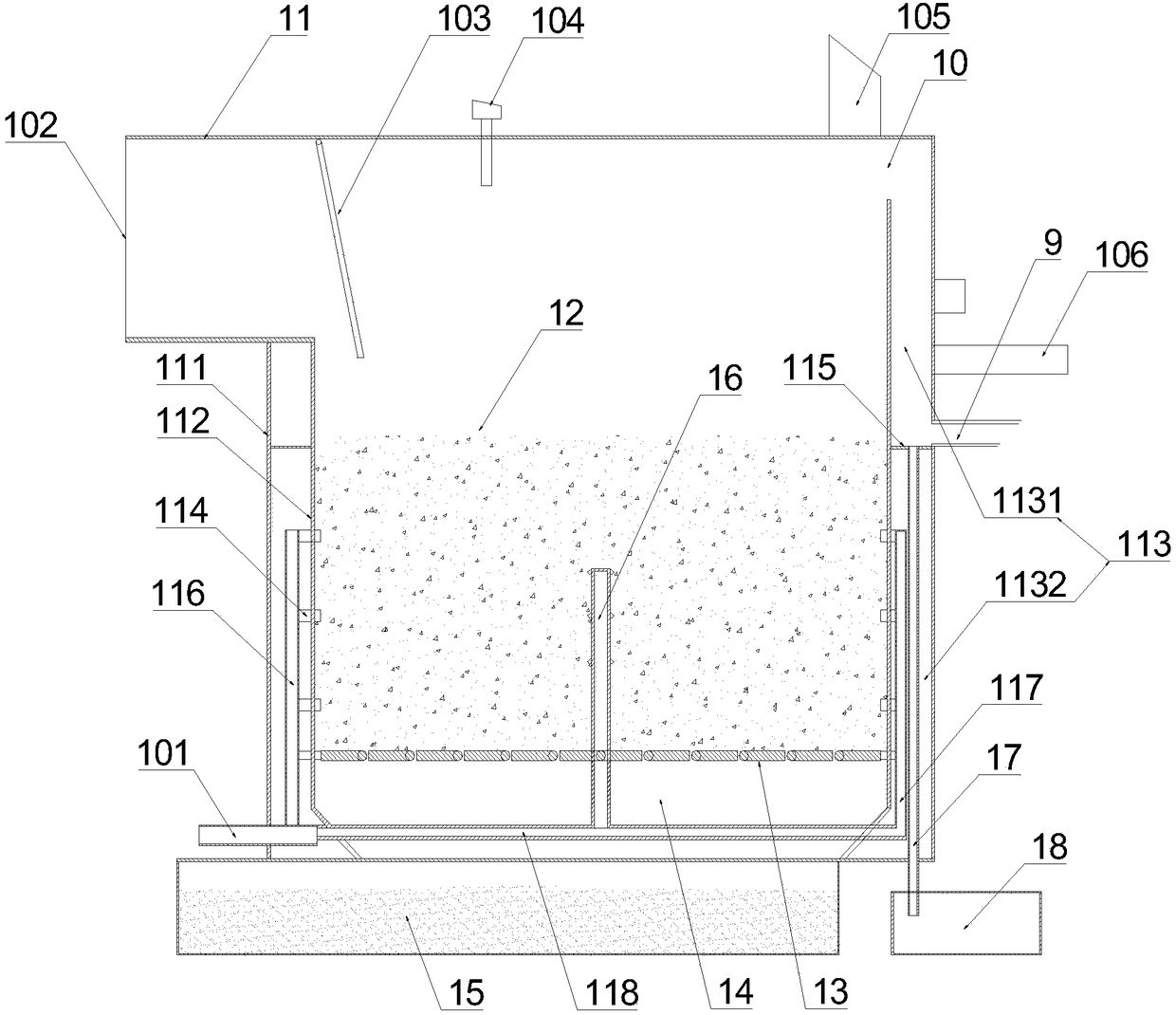

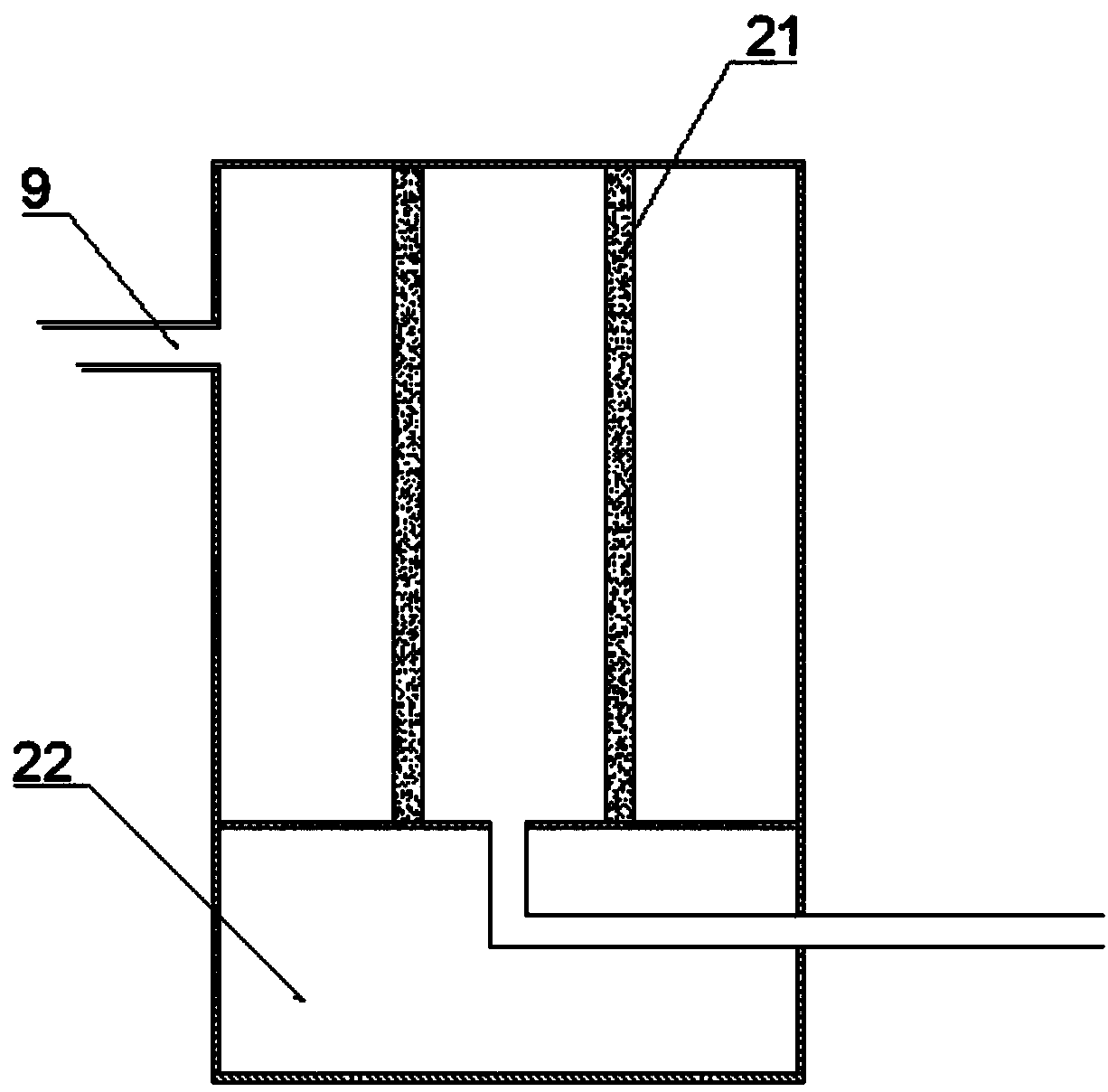

[0043] An organic waste treatment device, such as Figure 1-5 Shown, comprise cracking furnace 1, cracking furnace 1 comprises furnace body 11, is provided with air inlet 101 on furnace body 11, and air inlet 101 is located at the lower end of furnace body 11 side, is provided with in furnace body 11 successively from top to bottom. The processing chamber 12 and the turning furnace grate 13, the furnace body 11 includes an inner wall 112 and an outer wall 111, the inner wall 112 is provided with air holes 114, a cavity 113 is formed between the inner wall 112 and the outer wall 111, and a first ventilation pipe 116 is arranged in the cavity 113 , the air inlet 101 communicates with the air hole 114 through the first air pipe 16 , and the air inlet 101 communicates with the processing chamber 12 through the air hole 114 .

[0044] A cavity 14 is also provided in the body of furnace 11, and a turning grate 13 is arranged between the processing chamber 12 and the cavity 14. A sec...

Embodiment 2

[0064] A kind of organic waste processing device is the same as embodiment 1, difference is that the catalyst in the catalytic converter 6 of embodiment 2 is Pt, and carrier is honeycomb ceramics, and the opening rate is 60%;

[0065] An organic waste treatment process, including step 1: organic waste enters the treatment chamber 12 of the cracking furnace 1, and magnetized air is introduced at a temperature of 200°C for cracking, and the magnetized air enters the lower cavity 1132 through the air inlet, and part of the magnetized air is The air hole 114 on the inner wall 112 enters the treatment chamber 12 through the first ventilation pipe 116, and the remaining part of the magnetized air enters the treatment chamber 12 through the second ventilation pipe 117 from the turning pipe 16 on the turning grate 13, and the organic waste is cracked by the magnetized air The residue and tail gas are obtained, the residue enters the ash collection box 15 through the turning grate 13, t...

Embodiment 3

[0070] A kind of organic waste treatment device is the same as embodiment 1, and difference is that the catalyst in the catalytic converter 6 of embodiment 3 is Pt, and carrier is honeycomb ceramics, and the porosity is 80%;

[0071] An organic waste treatment process, including step 1: organic waste enters the treatment chamber 12 of the cracking furnace 1, and magnetized air is introduced at a temperature of 250°C for cracking, and the magnetized air enters the lower cavity 1132 through the air inlet, and part of the magnetized air is The air hole 114 on the inner wall 112 enters the treatment chamber 12 through the first ventilation pipe 116, and the remaining part of the magnetized air enters the treatment chamber 12 through the second ventilation pipe 117 from the turning pipe 16 on the turning grate 13, and the organic waste is cracked by the magnetized air The residue and tail gas are obtained, the residue enters the ash collection box 15 through the turning grate 13, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap