Grain drying device capable of circularly turning and applied to agricultural planting

A grain drying and agricultural technology, applied in the field of grain drying equipment, can solve the problems of inconvenient collection and drying of drying rice, unfavorable grain storage and processing, and inability to be uniformly heated, and achieves improved drying effect, long storage time, The effect of convenient delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

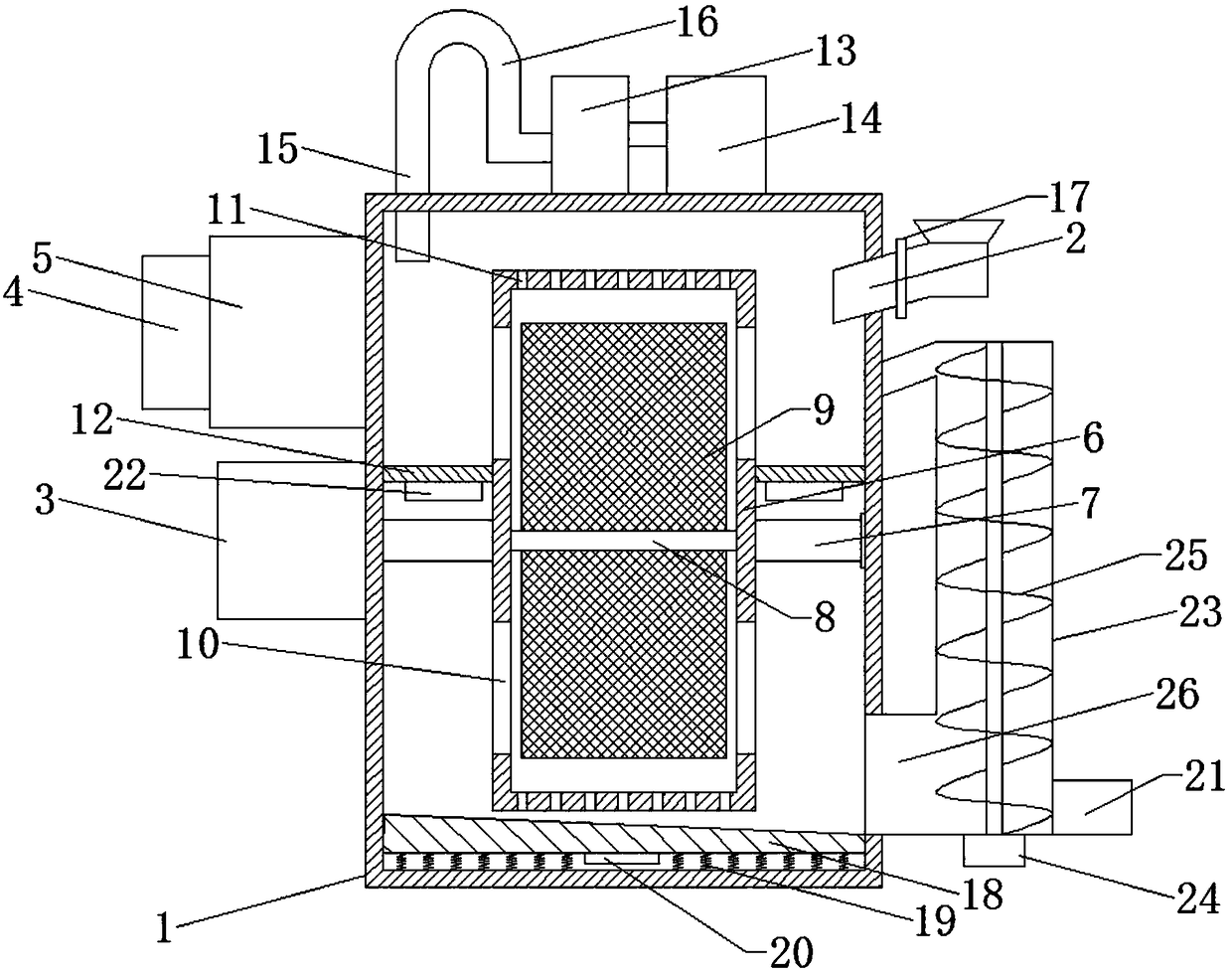

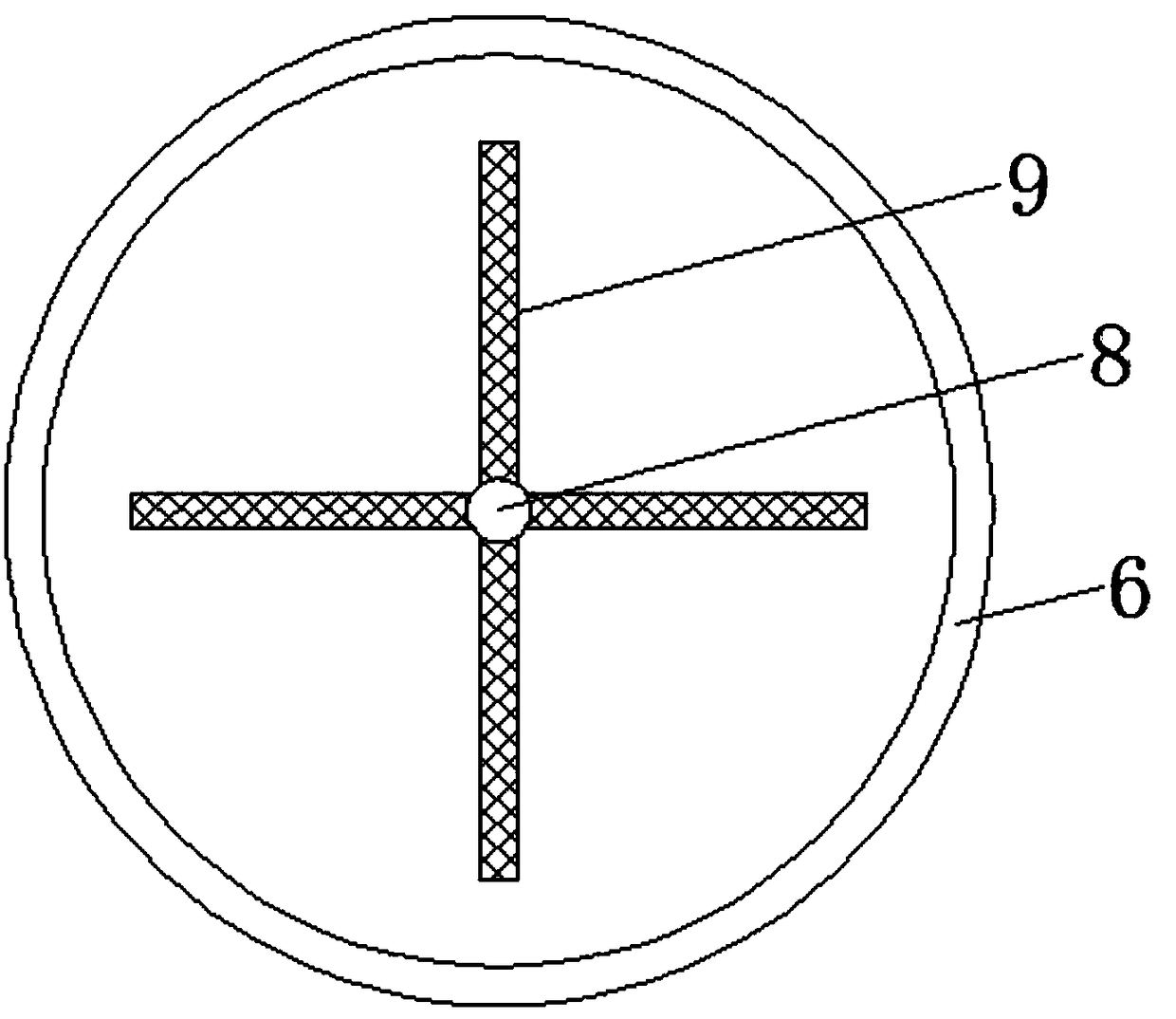

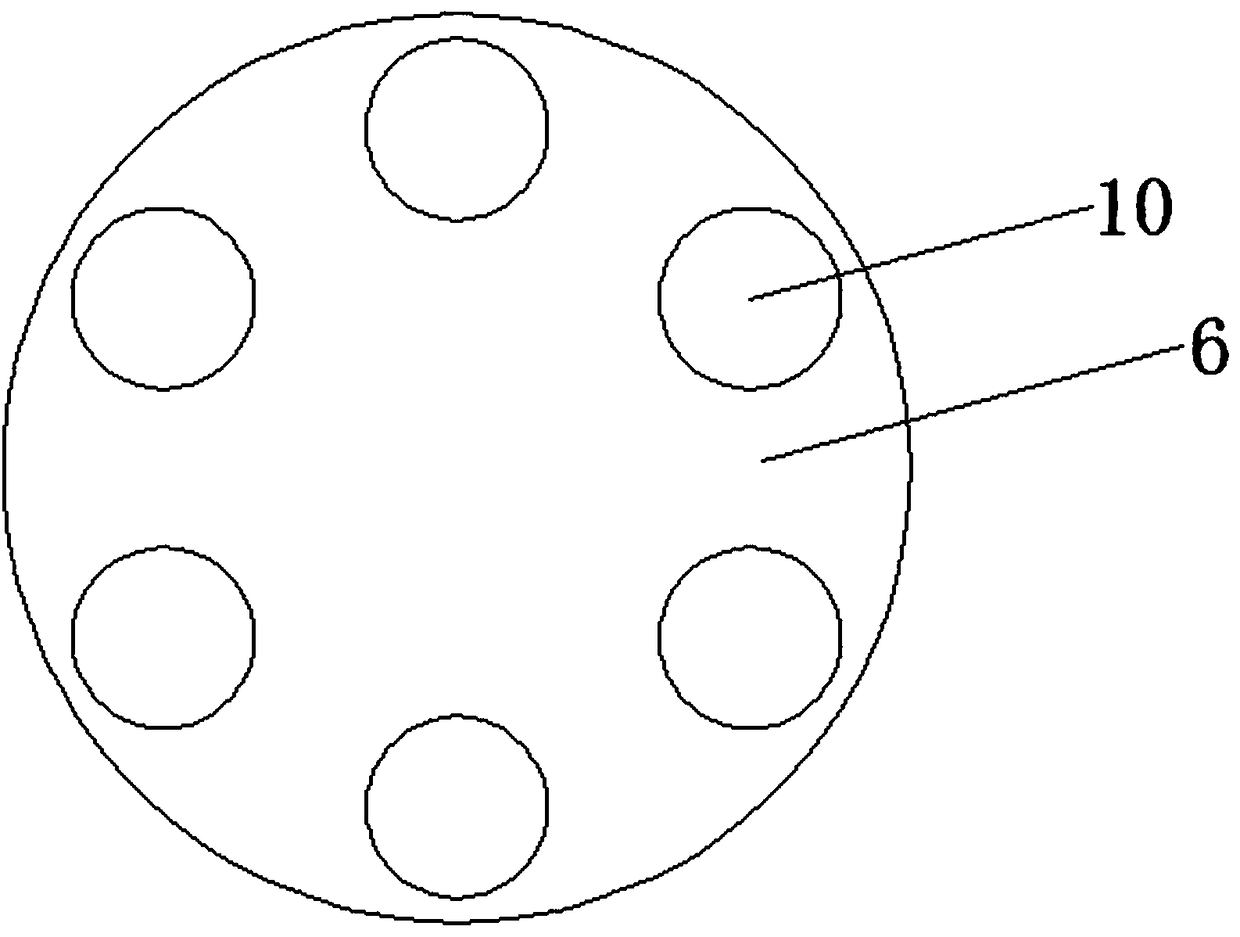

[0017] Please refer to the figure, in the embodiment of the present invention, a kind of grain drying equipment for agricultural planting with cyclic turning includes a box body 1, a feed pipe 2, a motor 3, a blower fan 4 and a heating box 5; There is a rotating drum 6 with a cylindrical structure, and a horizontal rotating shaft 7 is fixed on the outer central axis of the rotating drum 6, and the rotating shafts 7 on both sides are located on the same straight line, and one end of the rotating shaft 7 is connected to the inner wall of the box 1 through a bearing. , the other end passes through the box body 1 through the bearing fixed on the inner wall of the box body 1, the outer end is connected with the output shaft of the motor 3, and the rotating shaft 7 is driven to rotate by the motor 3, so that the rotating cylinder 6 rotates around its central axis; A horizontal partition 12 is fixed in the box 1 corresponding to the top of the rotating shaft 7, and the rotating cylind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com