Detection device for detecting verticality of bridge pier

A detection device and verticality technology, which is applied in the measurement of fixed angles and other directions, can solve the problems of low data accuracy and measurement error, and achieve the effects of extending service life, reducing wear and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

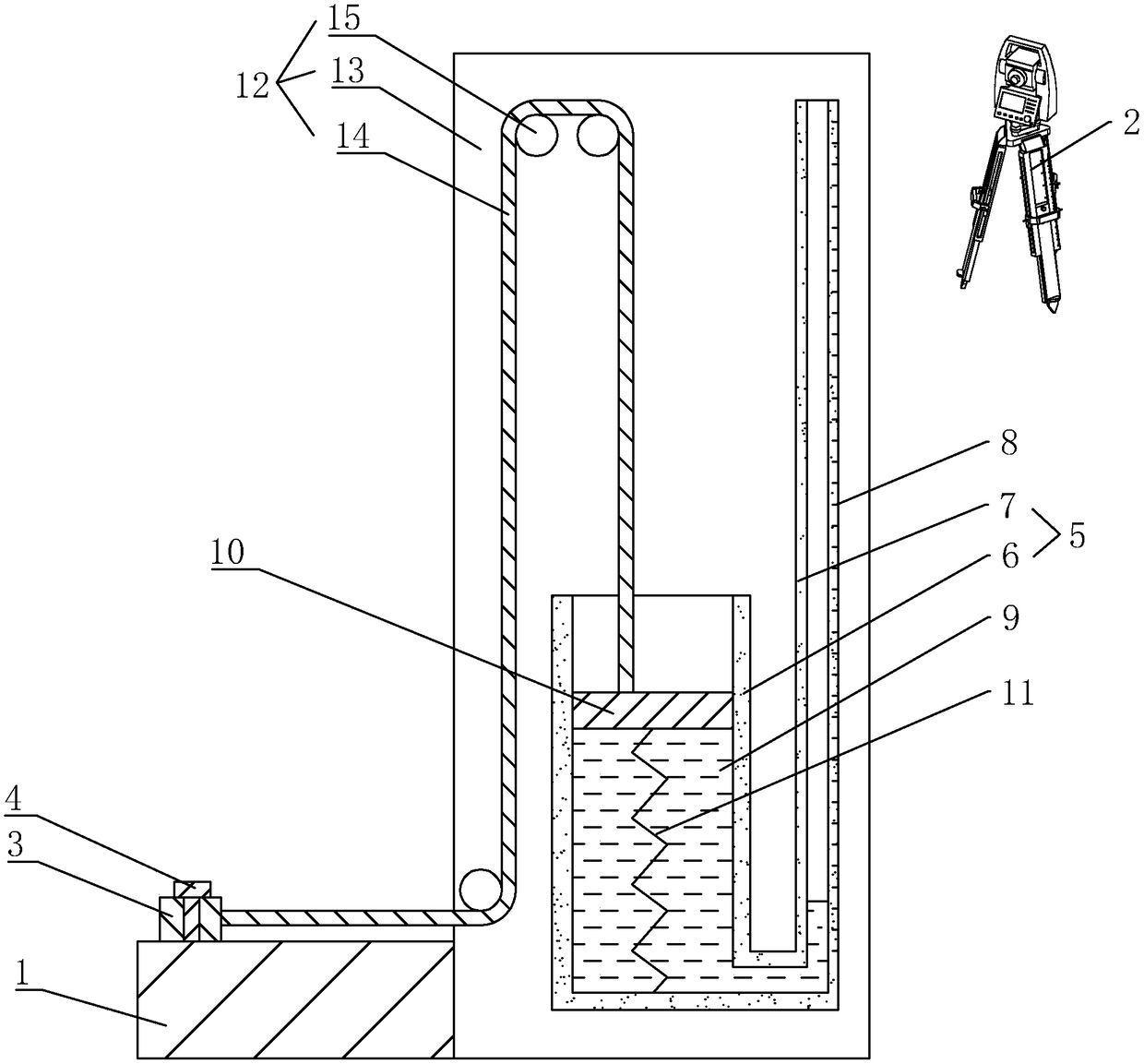

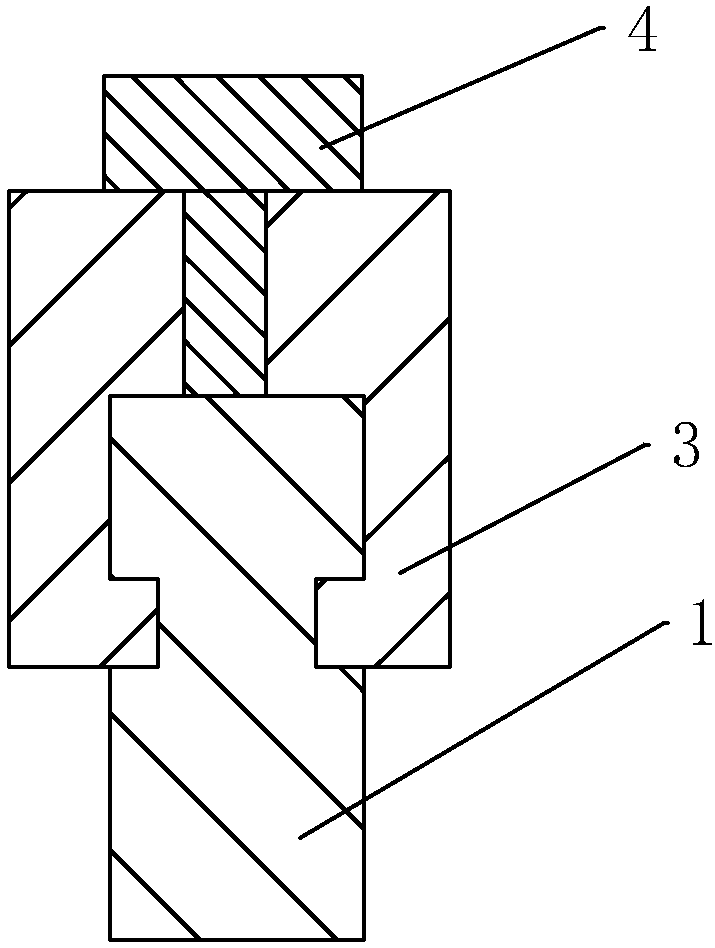

[0042] Such as figure 1 As shown, a detection device for verticality detection of bridge pier, including a straight rod 1 and a total station 2. Such as figure 1 and figure 2 As shown, the sliding sleeve on the straight rod 1 is provided with a sliding sleeve 3, and the sliding sleeve 3 is threadedly connected with a fixing bolt 4. When the fixing bolt 4 is screwed until it is against the straight rod 1, the sliding sleeve 3 is fixed relative to the straight rod 1.

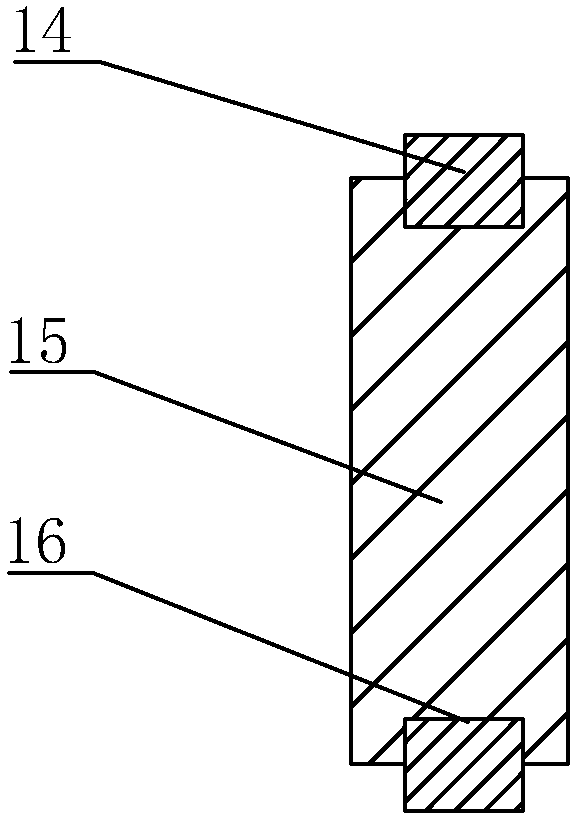

[0043] Such as figure 1 As shown, a reading amplification component 5 is provided on one side of the straight rod 1 , and the reading amplification component 5 can amplify the moving distance of the sliding sleeve 3 relative to the straight rod 1 . The reading amplification assembly 5 includes a liquid storage area 6 and a reading area 7 , and the reading area 7 is provided with a scale mark 8 for reflecting the moving distance of the sliding sleeve 3 . Both the liquid storage area 6 and the reading area 7 a...

Embodiment 2

[0054] Such as Figure 4 As shown, the difference between Embodiment 2 and Embodiment 1 is that the liquid storage area 6 is arranged vertically, the reading area 7 is arranged in an arc with the opening facing upwards, and the lower end of the reading area 7 is connected to the lower end of the liquid storage area 6 .

[0055] The reading area 7 arranged in an arc reduces the height required by the reading area 7 along the vertical direction, reduces the overall volume of the device, and is more convenient for users to read.

Embodiment 3

[0057] Such as Figure 5 As shown, the difference between the third embodiment and the first embodiment is that the liquid storage area 6 is arranged along the vertical direction, and the reading area 7 is arranged along the horizontal direction. A reading block 18 is slidably embedded in the reading area 7 , and the measuring liquid 9 is located between the reading block 18 and the sliding block 10 . The reading block 18 abuts against the inner wall of the reading area 7 and can slide relative to the reading area 7 . The side of the reading block 18 facing away from the liquid storage area 6 is provided with an elastic member 17 for resetting the reading block 18 . The elastic member 17 can be a spring, an elastic cord or the like. The elastic member 17 is parallel to the reading area 7 , and the two ends of the elastic member 17 are respectively fixedly connected to the reading block 18 and the frame 13 . When the elastic member 17 is in a natural state, the slider 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com