Method for simultaneously calibrating multiple MIMU errors based on lever arm compensation and positive and reverse speed

A technology of lever arm and rate, applied in the field of error calibration, can solve the problems of accuracy drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

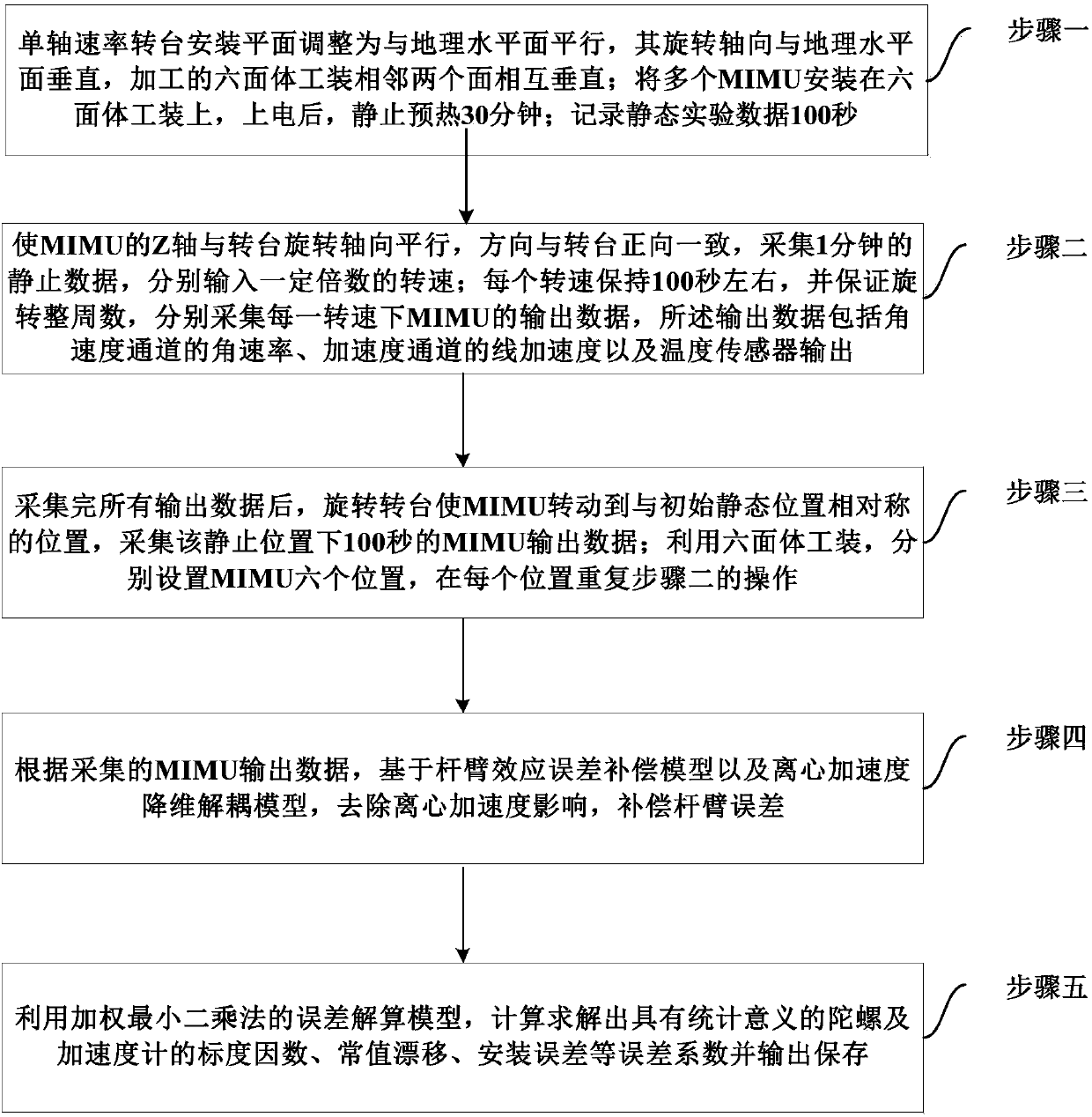

Method used

Image

Examples

Embodiment 1

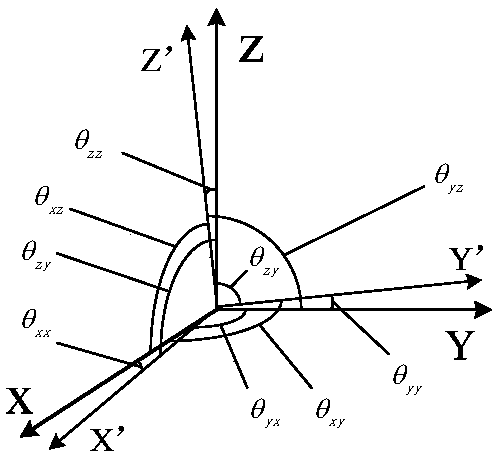

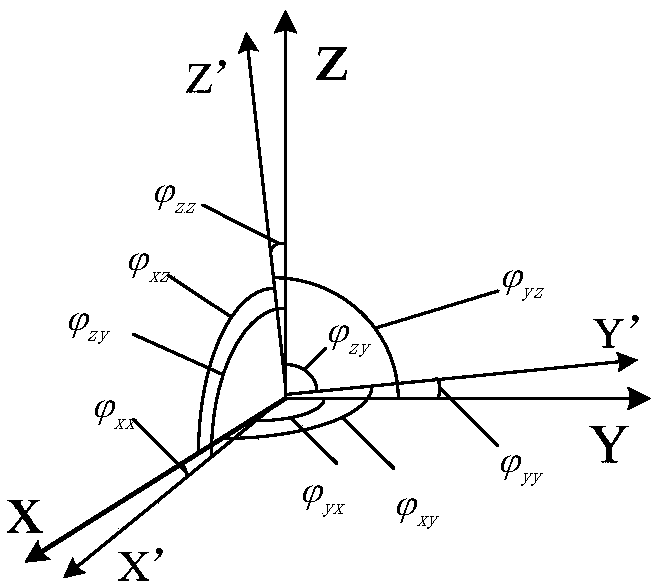

[0088] Embodiment 1 of the present invention is a micro-miniature inertial measurement system (Micro Inertial Measurement Unit, MIMU) designed based on a micro-electro-mechanical system (Micro-Electro-Mechanical System, MEMS), including a micro-miniature gyroscope, an accelerometer, a barometer, an electronic compass, etc. The sensor, through the movement of the carrier, generates information such as angular velocity and acceleration to achieve the purpose of measuring the movement of the carrier. Aiming at the problem that its installation error is relatively large compared with the traditional inertial measurement unit, according to the analysis of the influence mechanism of the corresponding lever arm effect and combined with the mathematical statistical model of error drift, a calibration method using a single-axis rate turntable and a hexahedron tooling is designed by applying the weighted least square method , can offset the error effects of ground speed and gravity, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com