Overall design and assessment method for hollow brick heat storage type heater

A heater and regenerative technology, applied in design optimization/simulation, instrumentation, calculation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

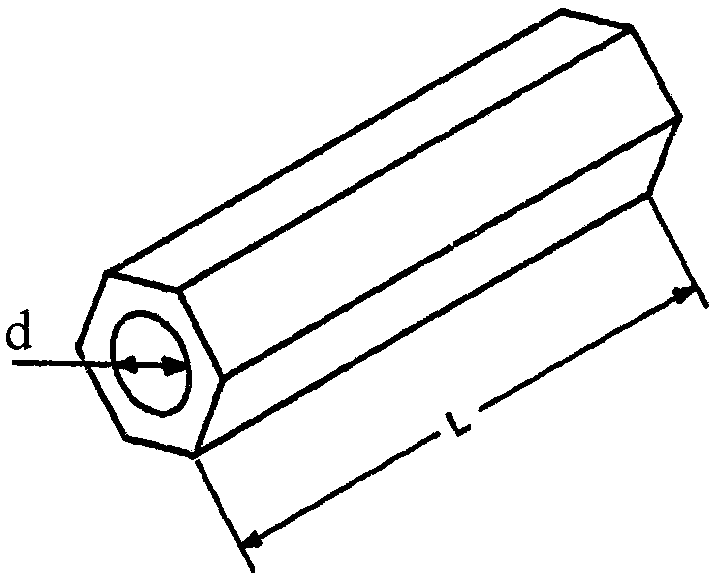

[0061] This embodiment provides a design and performance evaluation method for a heat storage unit of a hollow brick heater.

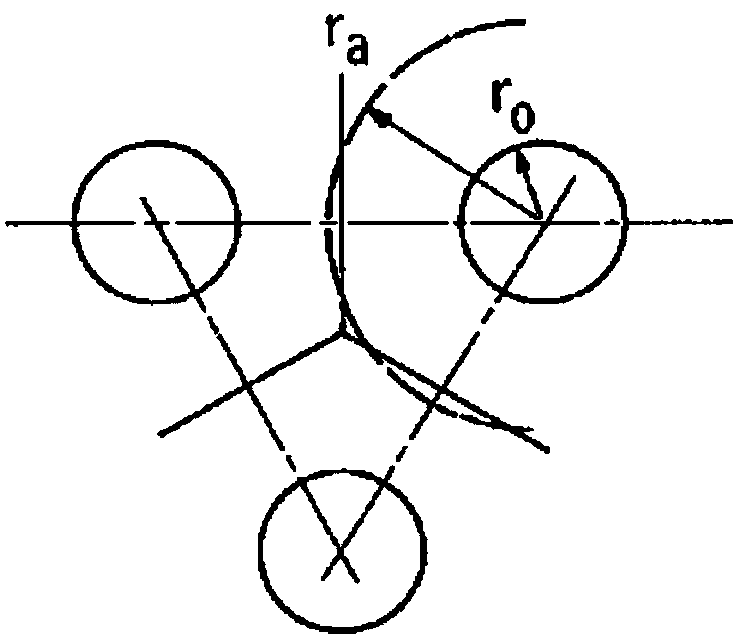

[0062] The basic design state requirements for the design of the hollow brick type regenerative heater in the embodiment are: air flow rate 3.0kg / s, simulated total temperature 2200K, simulated total pressure 5.0MPa, and effective running time of at least 50 seconds. Table 1 shows the geometric parameters of the heat storage unit in the design scheme and the related parameters calculated by this method. High-purity alumina bricks and zirconia bricks are used as heat storage materials. The alumina material is arranged in the lower temperature area (below 1900K) of the heater, and the zirconia material is arranged in the higher temperature area (1900K-2400K) of the upper part of the heater to meet the heating demand of the airflow temperature of 2200K.

[0063] Based on the geometric parameters of the hollow brick heat storage unit and the material char...

Embodiment 2

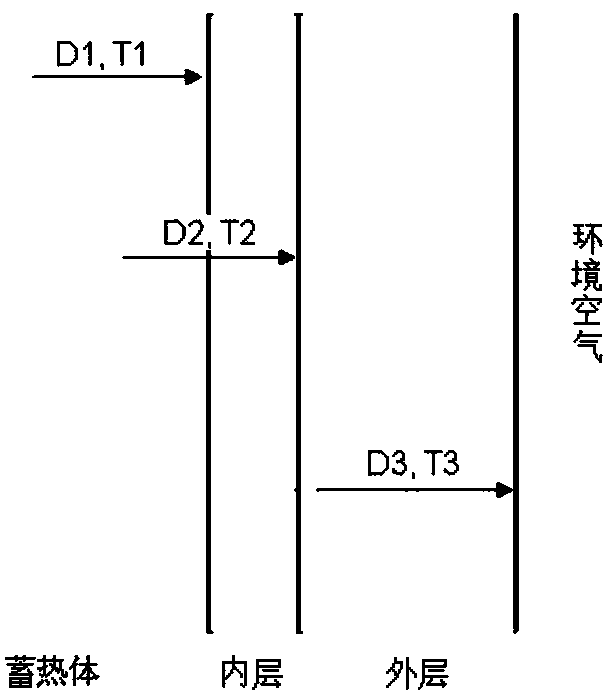

[0076] This embodiment is a checking method for the heat insulation layer. against Figure 8 This cylindrical insulation structure arrangement is checked and calculated. It is known that from the inside to the outside, each layer is heat storage unit, high temperature thermal lining, inner ring heat insulation layer, outer ring heat insulation layer, stainless steel shell, and the diameters of each layer are as follows: D1=450mm, D2=650mm, D3 =850mm, D4=1050, D5=1150mm. Using the one-dimensional steady-state heat conduction relationship of multi-layer cylinder insulation for verification, it can be determined that the heat loss power per unit height of the straight cylinder section in the middle of the heater is:

[0077]

[0078] The outer surface temperature of each layer is:

[0079]

[0080] Hot surface temperature (that is, the temperature of the outer surface of the heat storage unit) T in According to two calculations of = 2400K (high temperature section) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com