Livestock piggyback seeder and livestock piggyback sowing method

A seeder and piggyback technology, which is applied to the field of piggyback seeders for livestock, can solve the problems of inaccessibility of mechanical equipment, small sowing range, and large impact on sowing range, and achieve flexible sowing, large sowing range and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

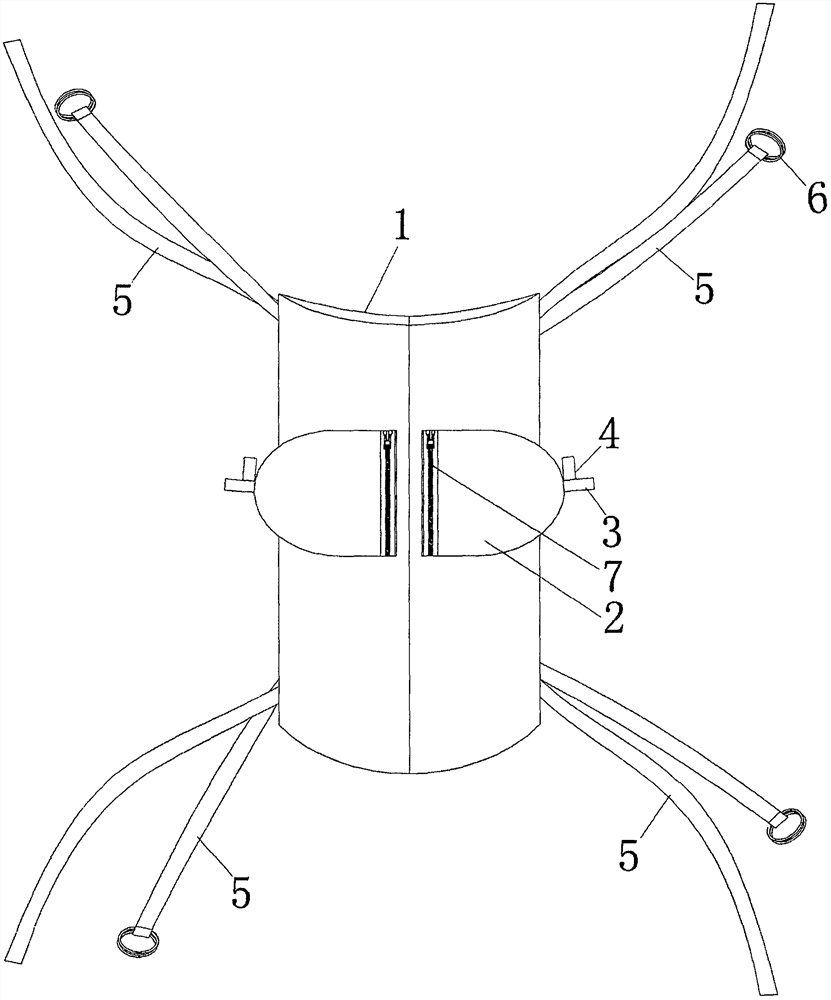

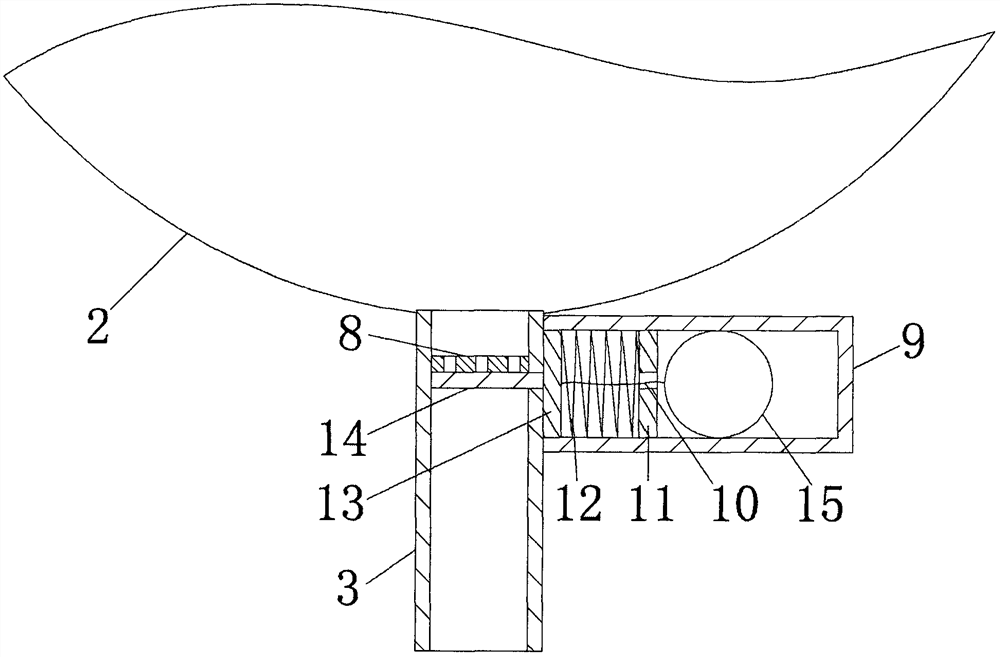

[0027] like figure 1 As shown, a piggyback seeder for livestock includes a saddle 1, a seed bag 2 arranged on the saddle 1, and a plurality of straps 5 arranged on the left and right sides of the front end and the left and right sides of the rear end of the saddle 1 The lower end of the seed bag 2 is downwardly provided with a seed outlet pipe 3 communicating with the inside of the seed bag 2 , and the seed outlet pipe 3 is provided with a switch mechanism 4 .

[0028] The present invention is tied on the sheep's back, and plant seeds (such as leguminous plant seeds) are loaded into the seed bag 2, and the sheep can sow at the same time during the process of walking and grazing on the grassland. Covering soil measures can be completed, it does not require manual and mechanical operations, low cost, and more energy-saving. Simultaneously, the grazing of flocks is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com