Rubber stopper puncher for chemistry laboratory

A chemical laboratory and rubber stopper technology, applied in the field of rubber stopper punchers for chemical laboratories, can solve the problems of difficult operation, non-compliance with requirements, irregular hole diameter, etc., and achieve the effect of easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

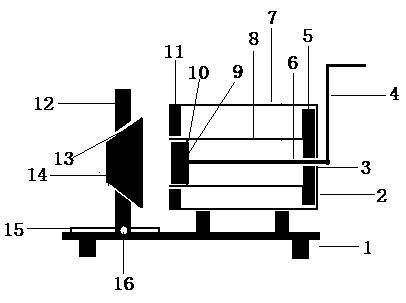

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] A rubber plug puncher for a chemical laboratory, characterized in that: the puncher includes a base 1, an outer tube 7, a cylindrical knife 8, a silk shaft 6, and a rubber plug clamping device;

[0022] The base 1 is an installation and connection platform for each component;

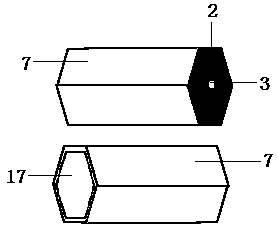

[0023] The outer tube 7 is horizontally fixed on the base 1, the outer tube 7 is hollow cylindrical, the cross section of the outer tube 17 is a regular polygon, one end of the outer tube 7 is provided with an end cover 2, and the center of the end cover 2 is provided with a shaft hole 3;

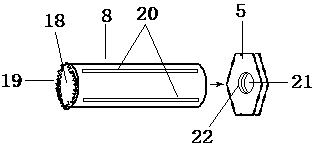

[0024] The cylinder knife 8 is used to drill holes on the rubber plug 14, the cylinder knife 8 is hollow cylindrical, the length of the cylinder knife 8 is equal to the length of the outer tube 7, and the cross section of the cylinder knife 8 is smaller than the cross section of the outer tube 7 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com