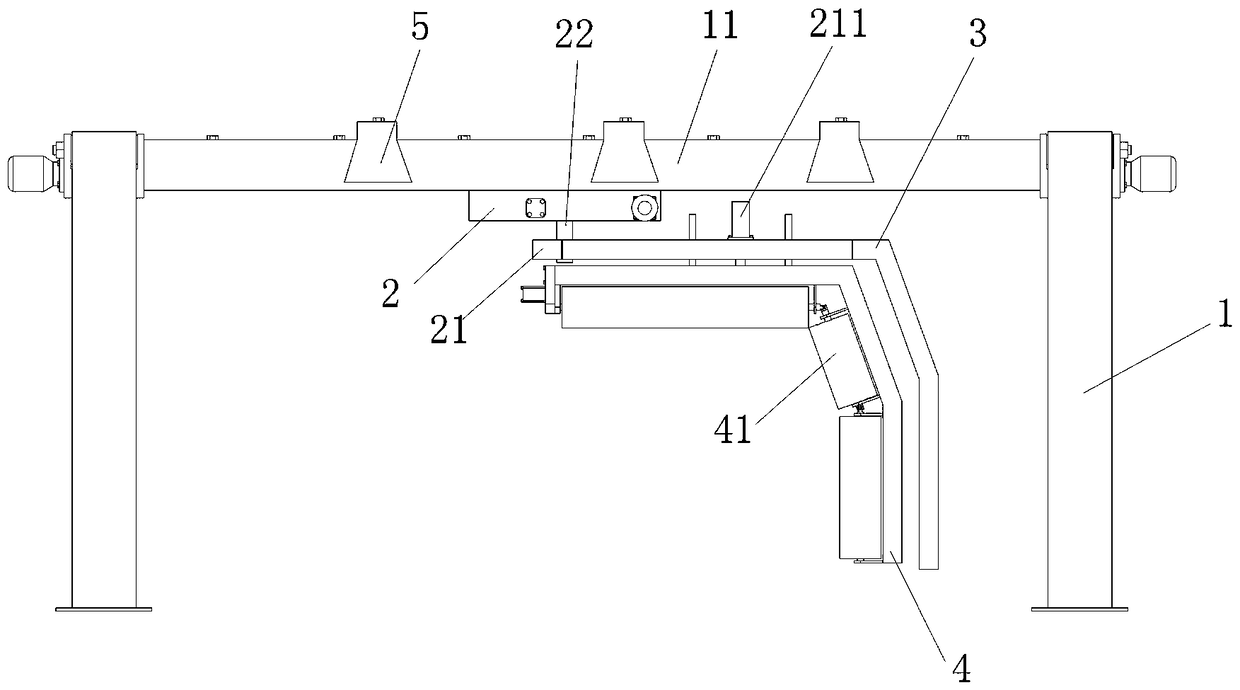

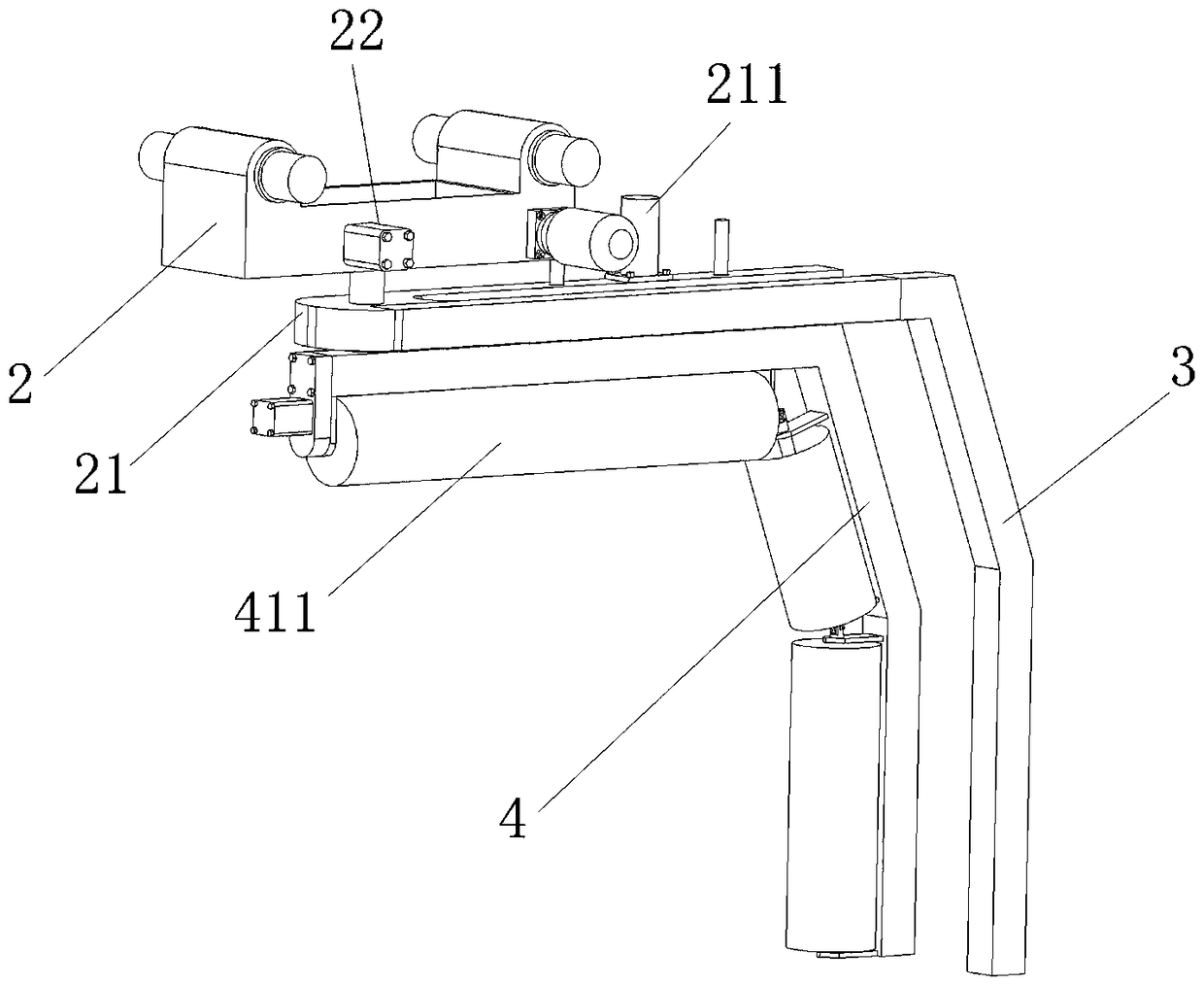

Gantry type automatic vehicle washing machine

A car washing machine and gantry-type technology, applied in vehicle drying devices, vehicle exterior cleaning devices, etc., can solve problems such as difficult installation, single function, complex structure, etc., achieve low investment and maintenance costs, simple overall structure, and good cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0021] A gantry type automatic car washing machine is provided with a chassis cleaning system at the bottom of the gantry 1 . The ground adopts a steel frame hollow design, which is convenient for the installation of chassis cleaning equipment and the collection of waste water during the cleaning process. The bottom spray group is set under the steel frame, and the nozzles are set in the gap of the steel frame. After the sensor that is arranged on the four corners of gantry frame 1 detects that vehicle is parked in place, the bottom spray controller opens and sprays water and detergent to the chassis part of the vehicle for cleaning. Longitudinal slide rail and rack are installed on the top of gantry frame 1, and crossbeam 11 is limited on the longitudinal slide rail, and motor and supporting gear set are installed on crossbeam 11, and gear set meshes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com