Device capable of automatically classifying and recycling carbon powder

A recycling device, automatic sorting technology, applied in the direction of transportation and packaging, loading/unloading, conveyor objects, etc., can solve the problems of polluting the environment, affecting the quality of toner, high cost and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

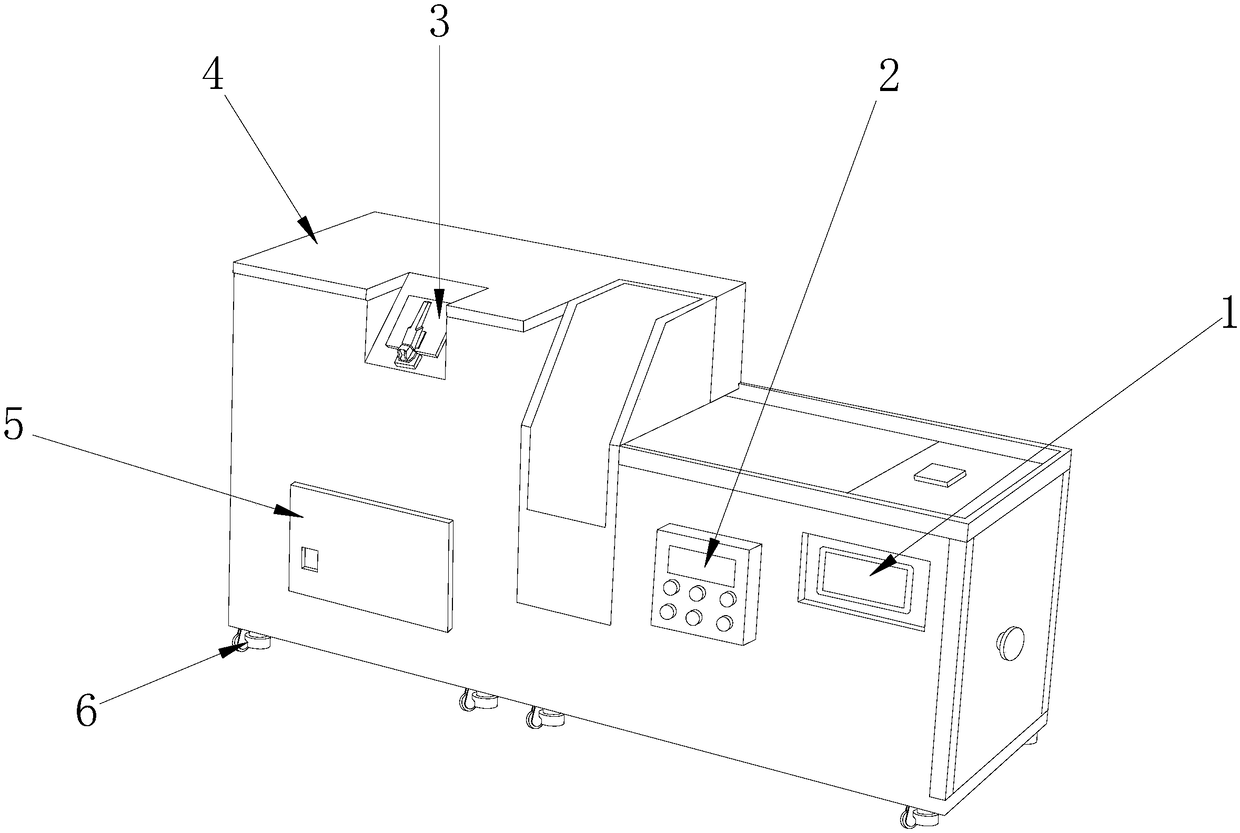

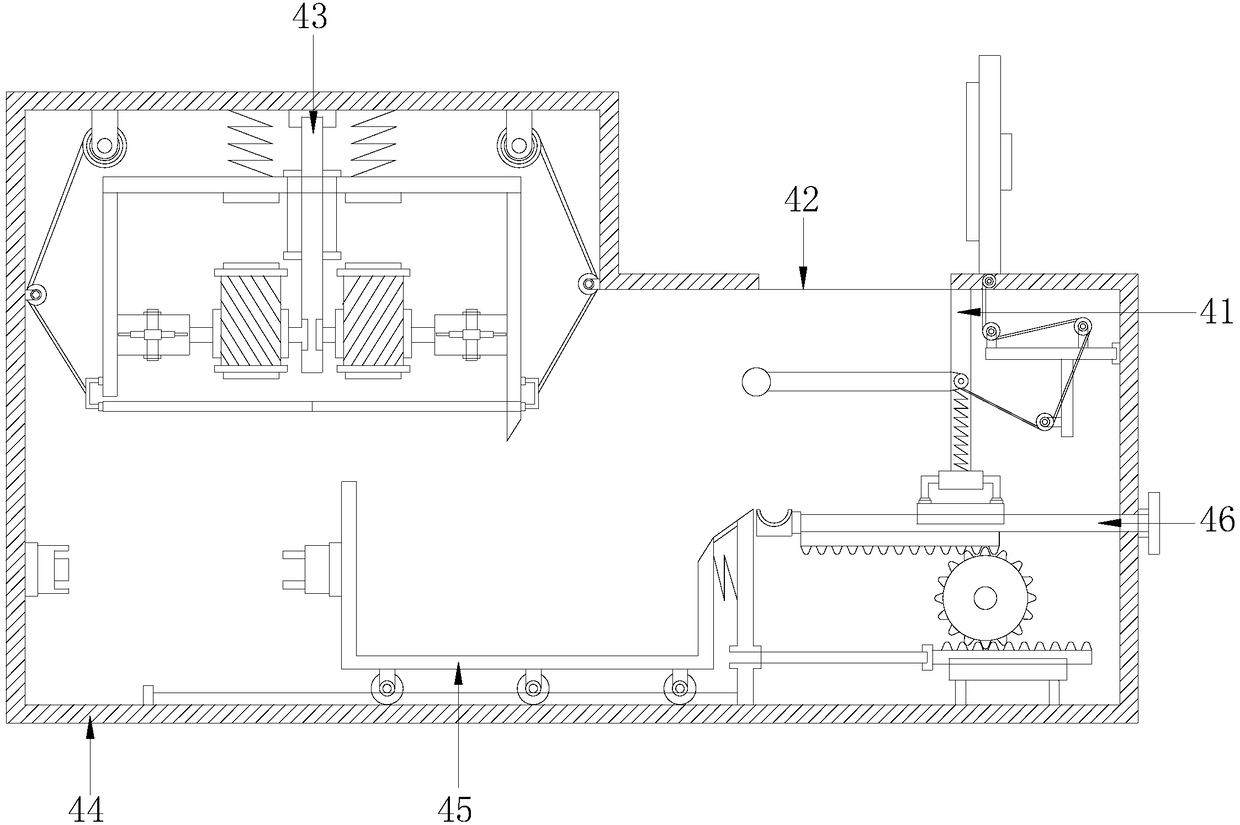

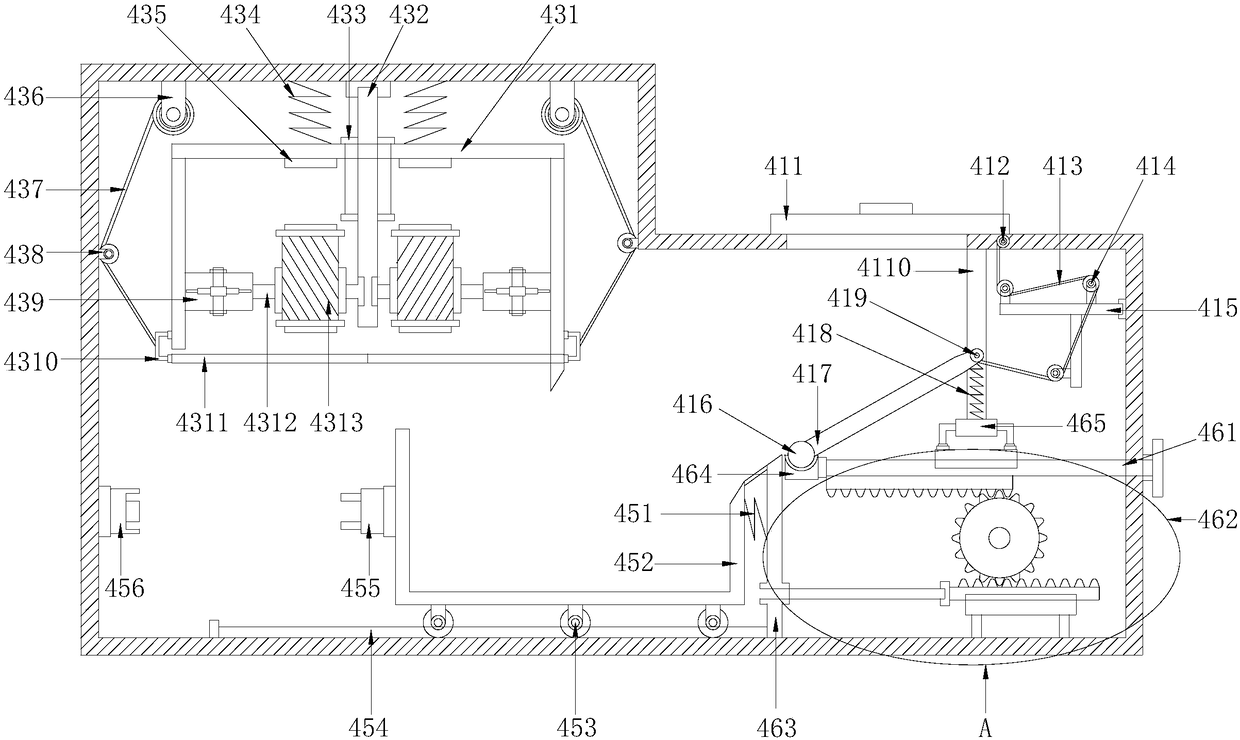

[0025] see Figure 1-Figure 5 , the present invention provides a device that can automatically classify and recycle carbon powder. Its structure includes a feeding observation window 1, a controller 2, an emergency power switch 3, a carbon powder recovery device 4, a material retrieving hatch cover 5, and universal casters 6. , the bottom of the toner recovery device 4 is evenly and equidistantly provided with eight swivel casters 6, the swivel casters 6 and the toner recovery device 4 are threaded, and the groove on the top of the toner recovery device 4 An emergency power switch 3 is provided, the emergency power switch 3 is electrically connected to the toner recovery device 4, the front end of the toner recovery device 4 is provided with a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com