Energy-saving dyeing machine

A dyeing machine and dyeing tank technology, applied in the field of dyeing machines, can solve the problems of increasing the burden and cost of sewage treatment, unfavorable cost control of the dyeing process, etc., and achieve the effects of easy follow-up cleaning, simple structure, and improved use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

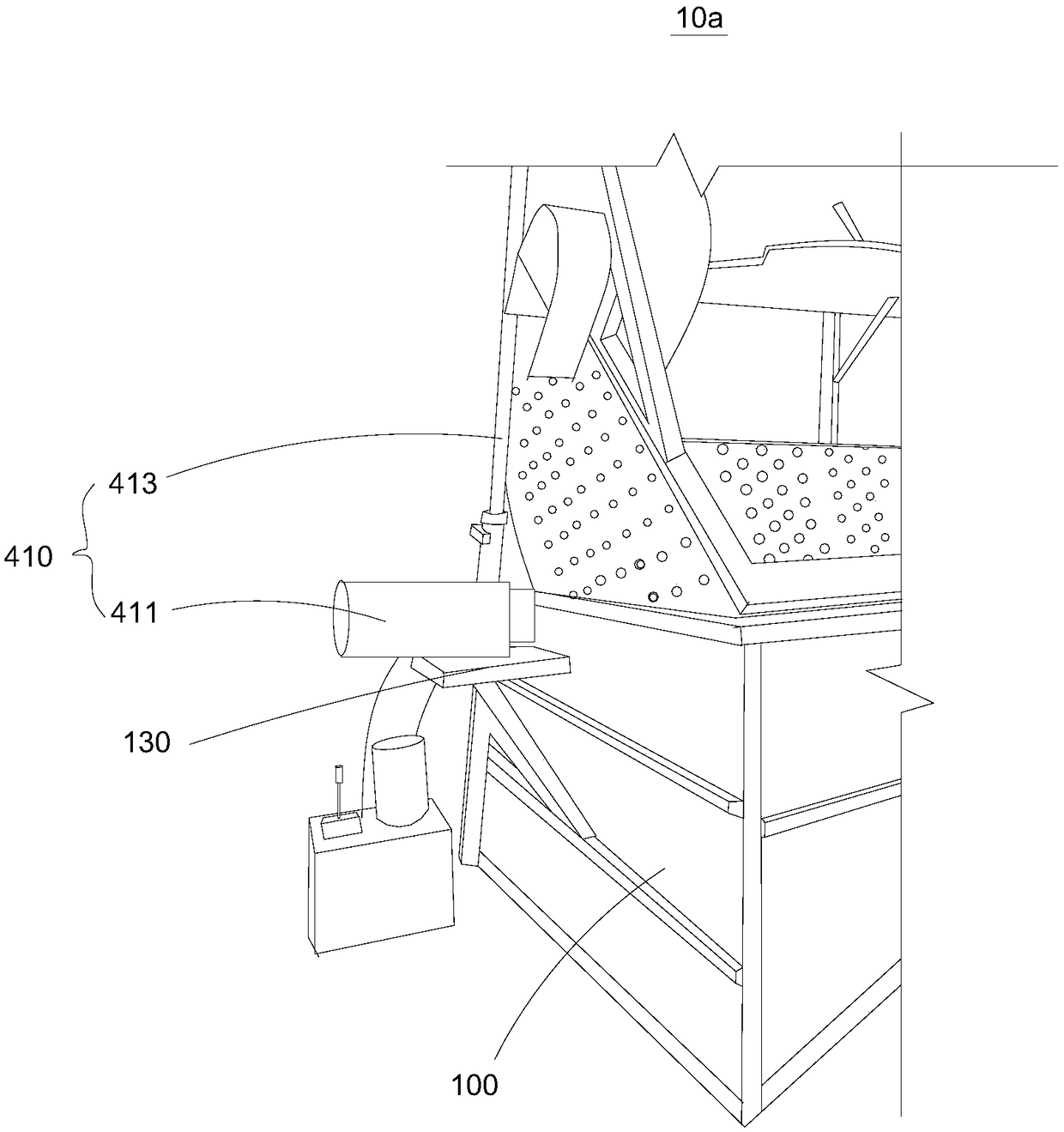

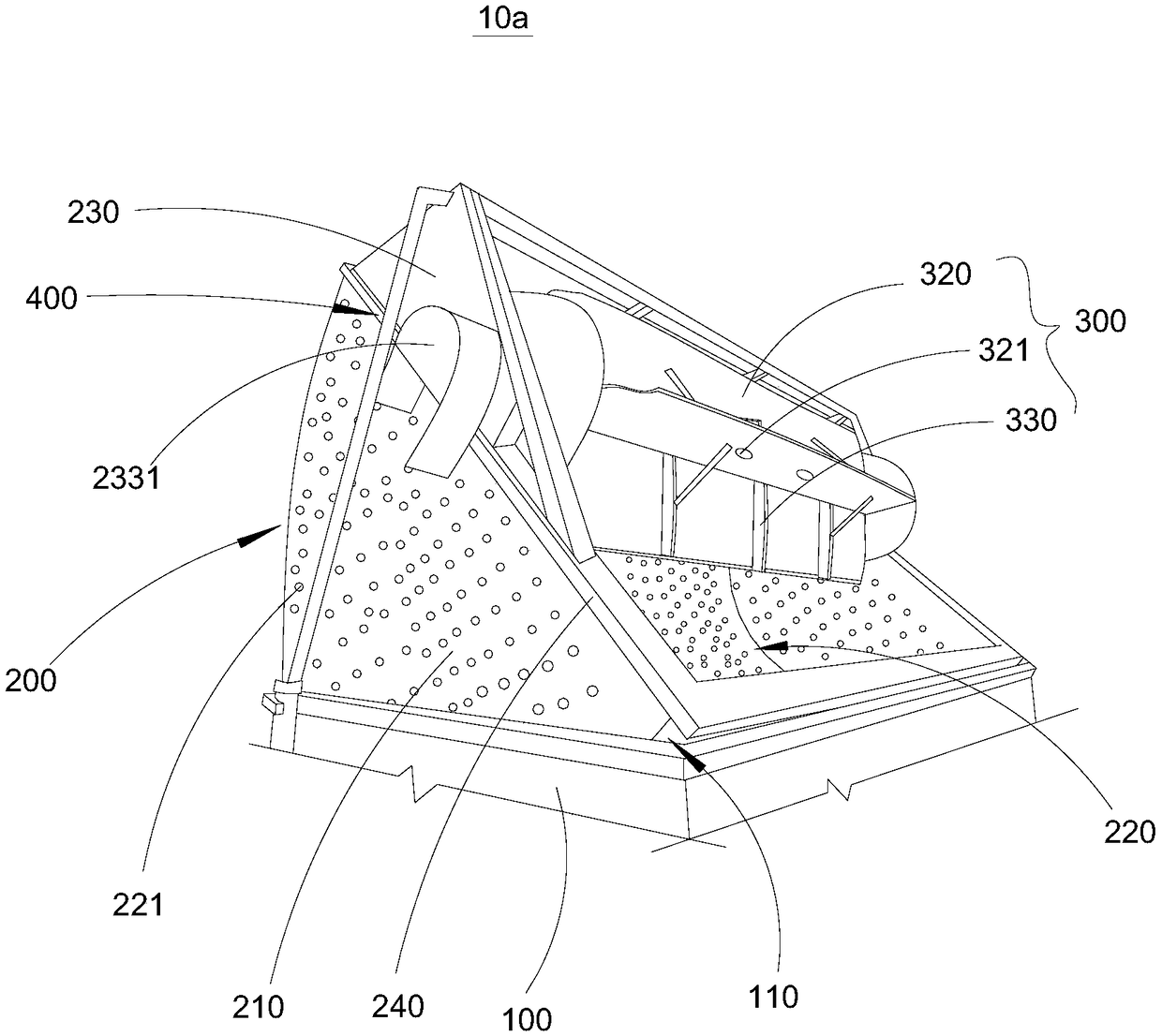

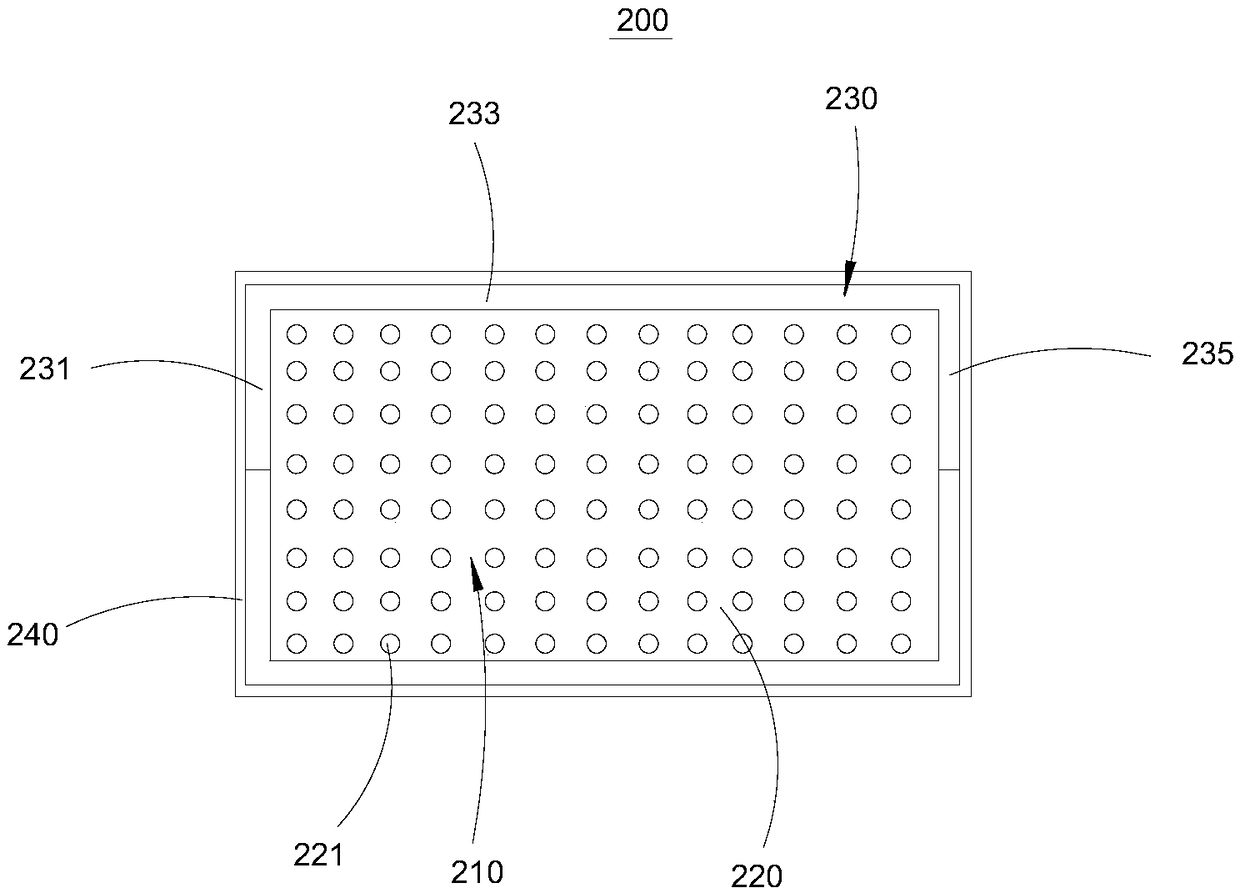

[0023] Please also refer to figure 1 as well as figure 2 , the present embodiment provides an energy-saving dyeing machine 10a, which includes a dyeing machine main body 100, a filter mechanism 200, a stirring mechanism 300, and a power mechanism 400.

[0024] Wherein, the main body 100 of the dyeing machine is provided with a first dyeing tank 110, which is used to hold the dye solution, and then dye sheepskin, rabbit skin or other furs or textiles. Wherein, the longitudinal section of the first dyeing tank 110 can be trapezoidal, rectangular, hemispherical, etc. In this embodiment, the longitudinal section of the first dyeing tank 110 is semicircular, and the projection of the first dyeing tank 110 on the horizontal plane is a rectangle. Facilitate the discharge of the dye solution in the later stage.

[0025] The main body 100 of the dyeing machine is provided with a drain port (not shown), and the first dyeing tank 110 communicates with the drain port for discharging th...

Embodiment 2

[0049] Please refer to Figure 4 This embodiment provides an energy-saving dyeing machine 10b, which is substantially the same as the energy-saving dyeing machine 10a of the first embodiment, the difference between the two is that the energy-saving dyeing machine 10b of this embodiment also includes a water treatment device 500 .

[0050] Specifically, the liquid outlet is connected with a liquid outlet pipe 510 , and the liquid outlet pipe 510 is in communication with the water treatment device 500 .

[0051] Wherein, the water treatment device 500 includes a reclaimed water outlet (not shown in the figure), and the reclaimed water outlet is selectively communicated with the dyeing tank. The liquid inlet of the one-way valve 530 is located on the side of the one-way valve 530 close to the water treatment device 500, and is used for reusing the recovered gray water, effectively saving water resources.

[0052] The working principle of the energy-saving dyeing machine 10b is: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com