Mounting adjusting method for prefabricated wall plate

A prefabricated wall panel, installation and adjustment technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems that the prefabricated components cannot be fixed immediately, the verticality cannot be guaranteed, and the construction difficulty, etc., to reduce the construction risk, The effect of flexible construction and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

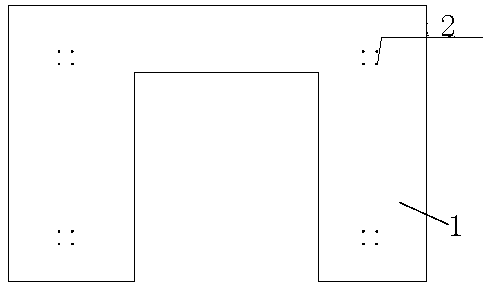

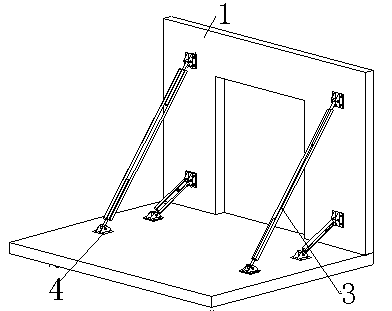

[0017] Such as figure 1 , 2 Shown: a kind of installation adjustment method of prefabricated wall panel, it comprises the following steps:

[0018] According to the requirements of the prefabricated construction process, the installation and adjustment of prefabricated wall panels is the key to construction, but the prefabricated components cannot be fixed immediately after they are installed in place, and the verticality cannot be guaranteed, which brings certain risks or construction difficulties to the construction. The advanced construction method effectively avoids the above problems, and the construction is convenient, safe and low in construction cost.

[0019] Specific implementation steps:

[0020] Before implementation begins:

[0021] According to the dimensions, weight and other factors of the prefabricated wallboard 1, the PC component factory is required to reserve two sets of bolt holes 2 on the prefabricated wallboard (800mm away from the upper and lower edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com