Automatic detecting and adjusting system for surge of centrifugal compressor

A centrifugal compressor, automatic detection technology, applied in the direction of machines/engines, mechanical equipment, non-variable pumps, etc., can solve the problems of centrifugal compressor surge hazards, achieve good results, and prevent additional costs The effect of increasing and liberating the labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

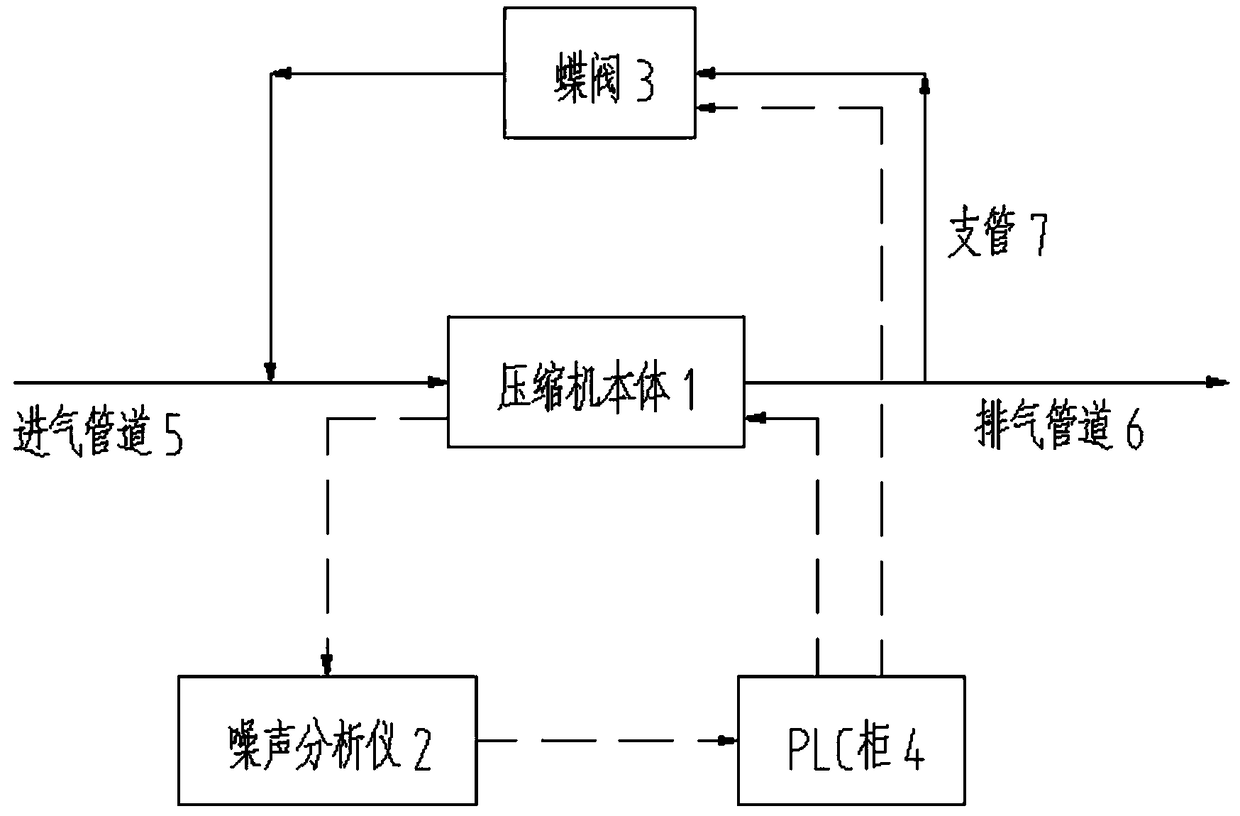

[0022] The structural diagram of an automatic detection and adjustment system for centrifugal compressor surge is shown in figure 1 As shown, the system mainly includes a compressor body 1, a noise analyzer 2, a butterfly valve 3, a PLC cabinet 4, an air intake pipe 5, an exhaust pipe 6, and a branch pipe 7, etc., and a PLC controller is installed in the PLC cabinet 4. Among them, the noise analyzer has the function of analyzing the decibels of noise and the frequency of noise; the butterfly valve is a proportional regulating valve that can precisely control the opening of the valve; the PLC cabinet communicates with the noise analyzer, butterfly valve, and compressor body Signal.

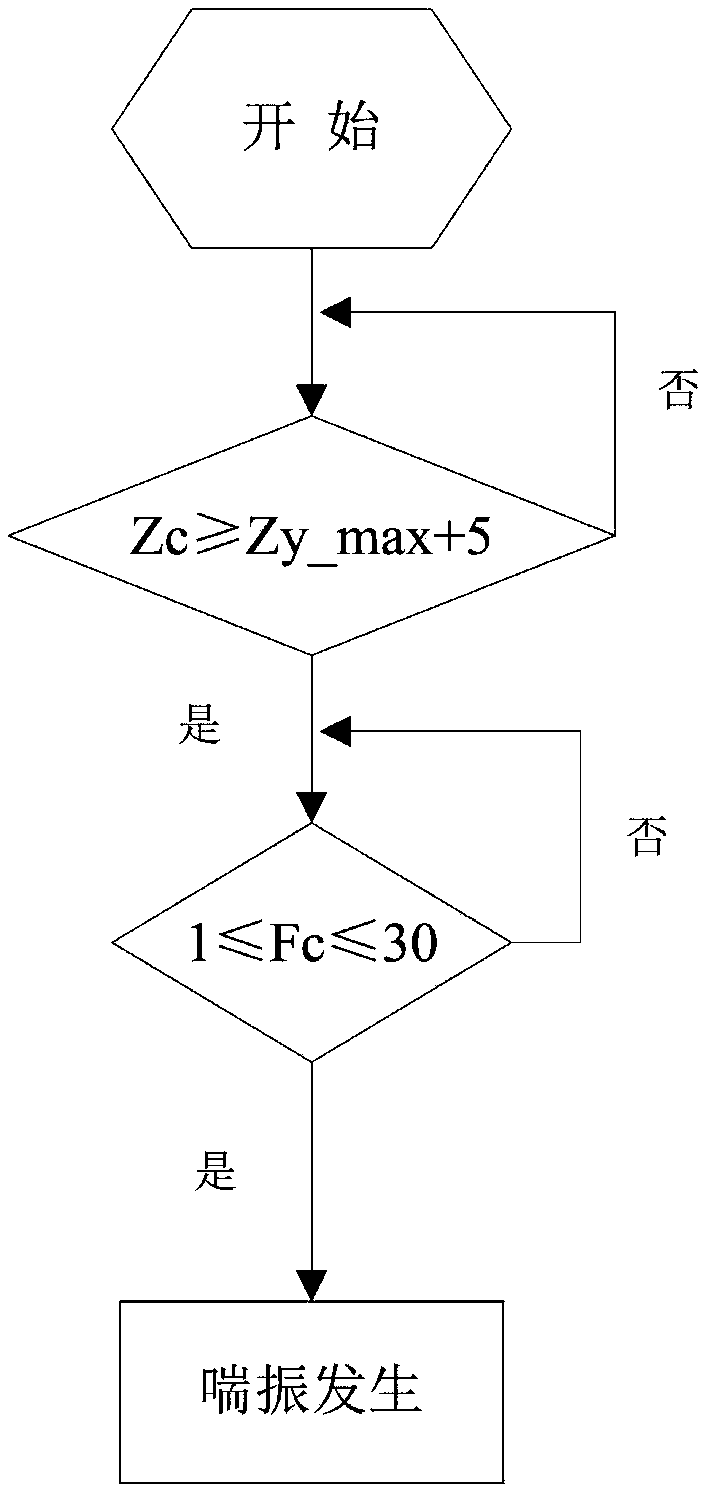

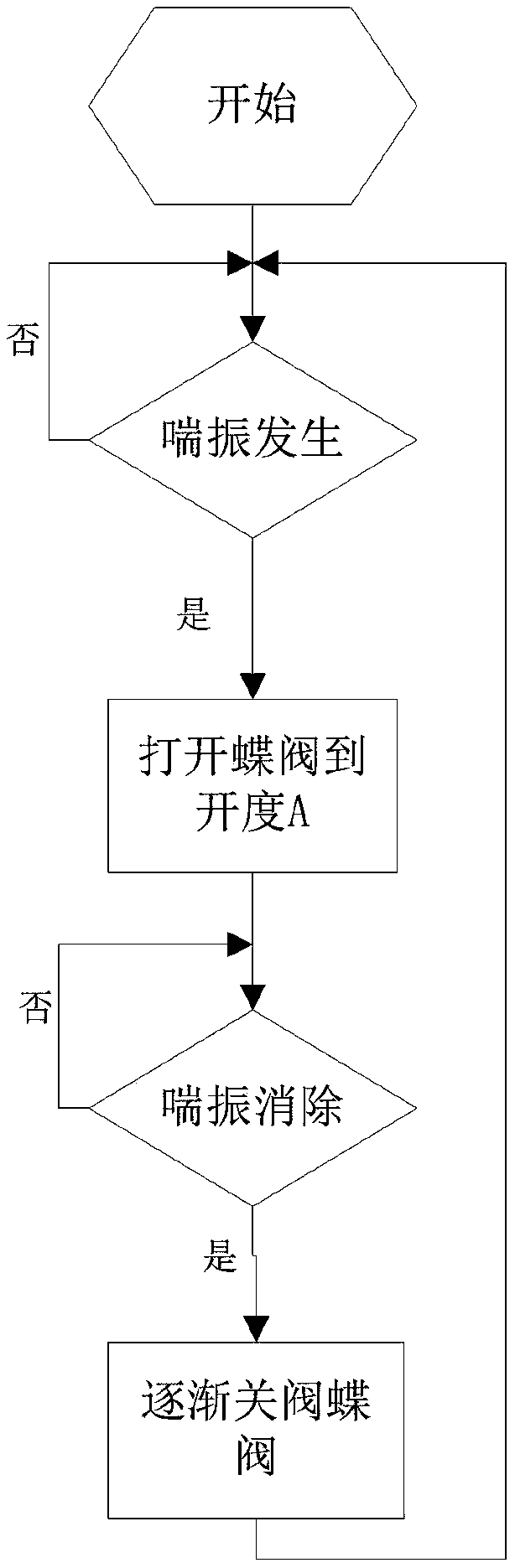

[0023] The principles and methods of compressor surge automatic detection are as follows:

[0024] When the compressor surges, it will emit abnormal airflow noise, which is much louder than the noise during normal operation of the unit, and the noise emitted during surge is generally low-frequency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com