Axial magnetic field flux switching motor with staggered double-stator hybrid excitation

A magnetic flux switching motor, hybrid excitation technology, applied in the direction of magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of insufficient magnetic adjustment range, large cogging torque and harmonic components, limited application, etc. Effective excitation area, cancellation of even harmonics, short magnetic circuit effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

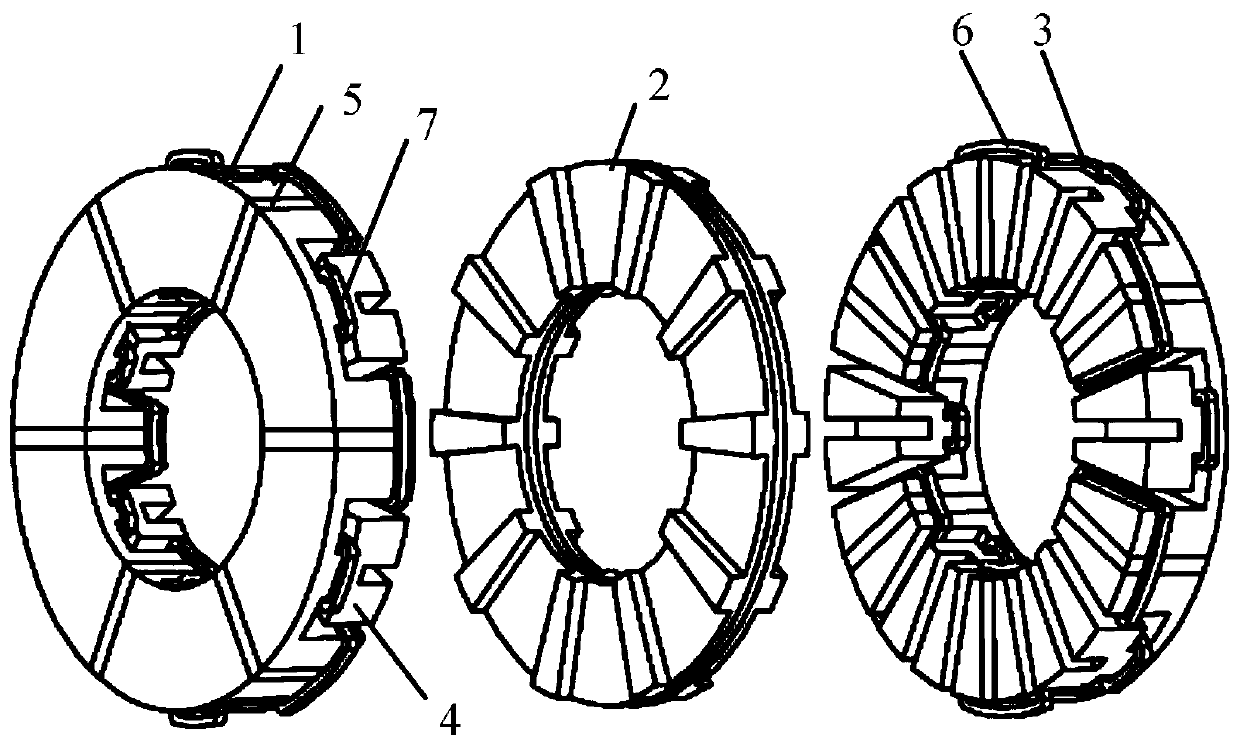

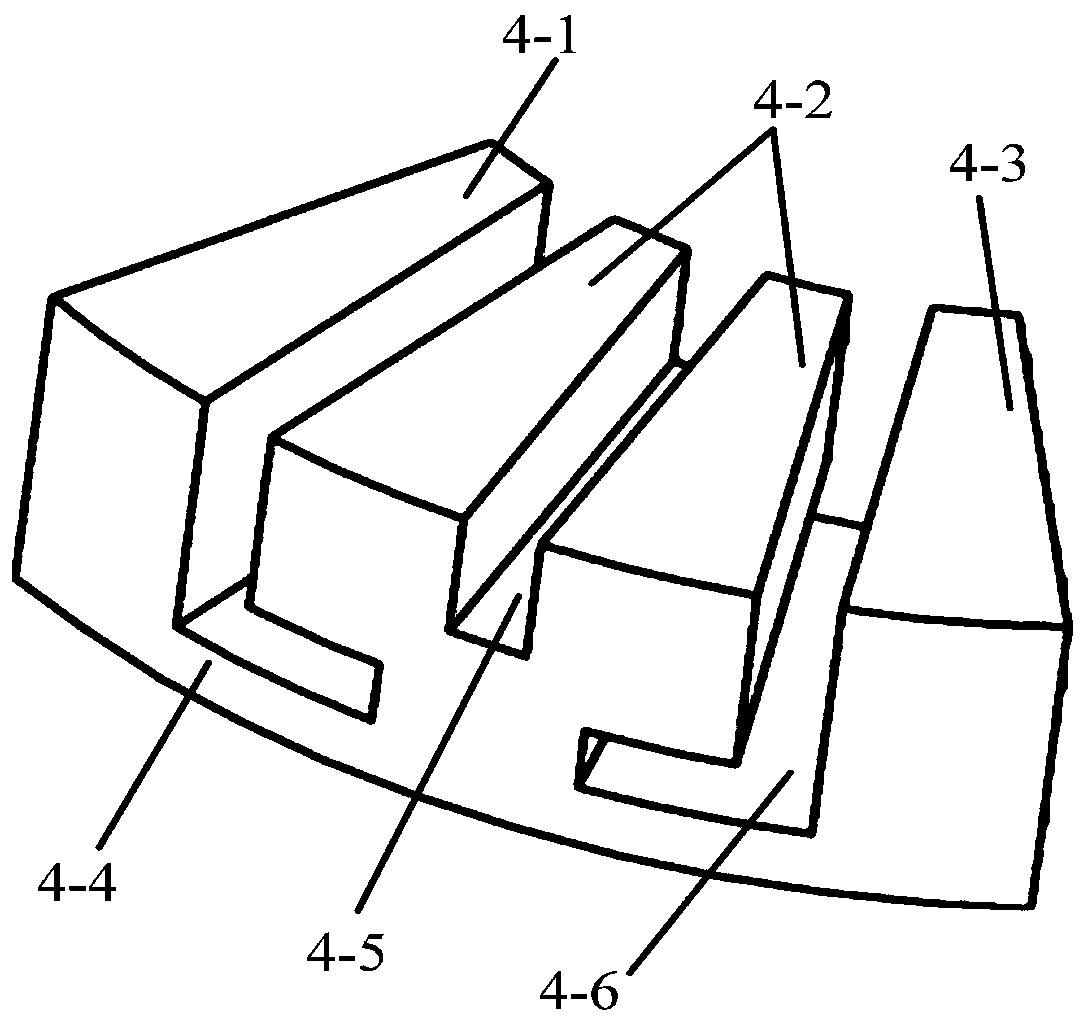

[0030] In this embodiment, the first stator 1 and the second stator 3 are assembled into a circle by 6 U and E combined core units 4 and 6 permanent magnets 5, and the rotor core a2-1 and the rotor core b2- 3 have 10 rotor teeth 2-4 respectively. The first stator 1 and the second stator 3 are installed at an angle staggered by 90° along the axial direction. The specific parameters are shown in Table 1.

[0031] Table 1

[0032]

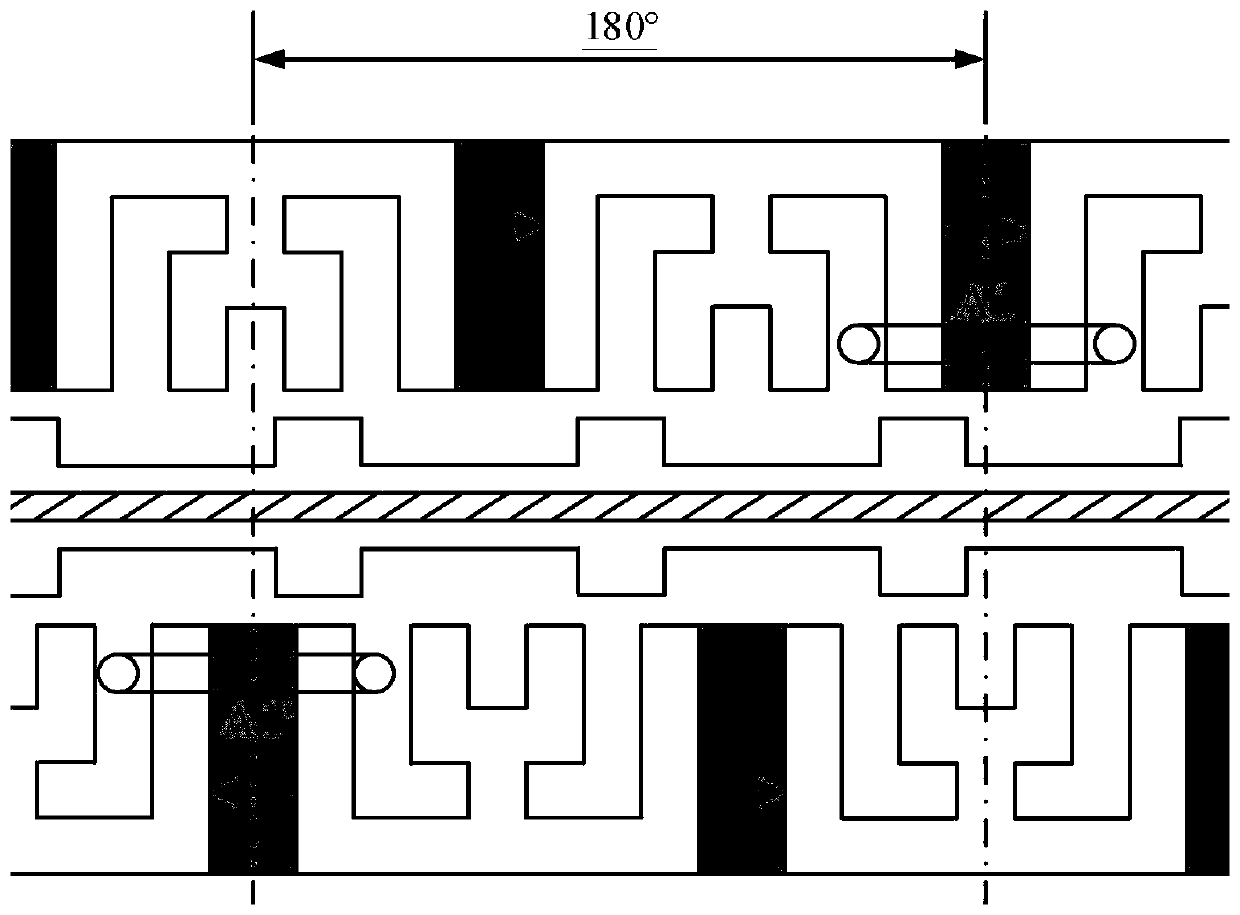

[0033] When the excitation current passed into the field winding 7 is zero, the air gap magnetic field is only provided by the permanent magnet 5, and when the rotor 2 runs to β 1 Angle, its permanent magnet flux path as Figure 5 As shown, the solid line is the A-phase winding, the long dashed line is the B-phase winding, and the short dashed line is the C-phase winding. Taking phase A as an example, according to the "minimum reluctance principle", the magnetic flux penetrates into the A1 winding in the direction of the arrow; when the rotor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com