High efficiency hardening furnace for resin grinding wheels

A technology of resin grinding wheel and hardening furnace, which is applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems affecting the effect of hardening treatment, hardening treatment time, and air quality, and achieve good practical use and promotion Value, good treatment effect, good hardening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

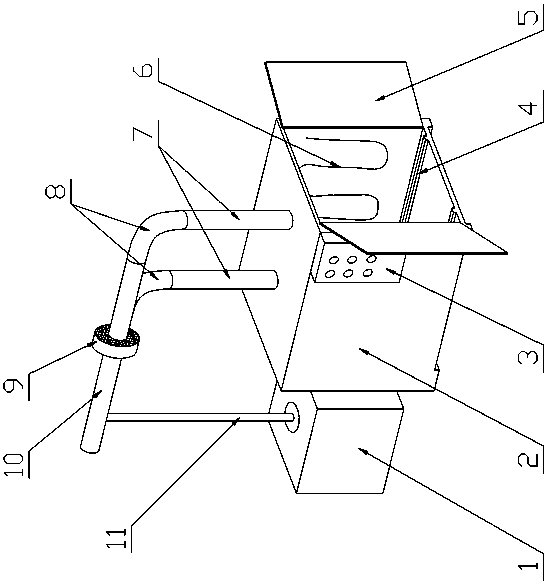

[0012] see figure 1 , the present invention is a high-efficiency hardening furnace for resin grinding wheels, which has a hardening furnace body 2, an electric heating wire 6 is arranged on the inner wall of the hardening furnace body, a double-opening furnace door 5 is arranged on the front side wall of the hardening furnace body, and a There is a controller 3, and the inside bottom of the hardening furnace body is provided with a track 4, which is convenient for the in-and-out transportation of the emery wheel; The gas pipeline is connected with a horizontal exhaust pipeline 10, and the joints between the horizontal exhaust pipeline and the two vertical exhaust pipelines are connected by a smooth arc pipe 8, and the middle part of the horizontal exhaust pipeline is provided with a gas filter 9, An air induction pipe 11 is connected to the lateral exhaust pipe located outside the gas filtering device, and the air induction pipe is connected with an induced fan 1 .

[0013] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com