Single-sided H-shaped embossed PCM color coated steel sheet and produced process thereof

A technology of color-coated steel plate and production process, which is applied in the field of steel plate, can solve the problems of low production efficiency, achieve the effects of increasing output, ensuring product quality, and reducing secondary pressing processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

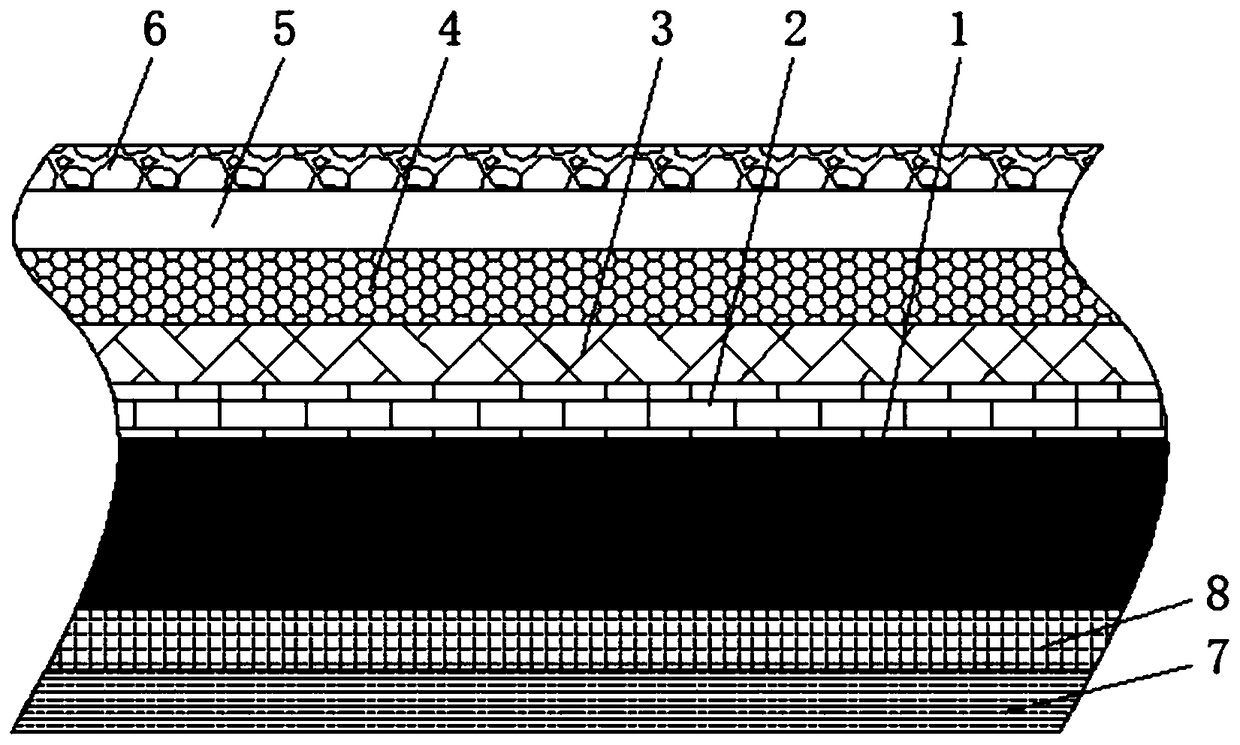

[0024] The present invention also provides a production process for single-sided H-shaped embossed PCM color-coated steel sheets, the specific steps of which are as follows:

[0025] S1, select the steel plate, the thickness of the steel plate after pickling and hardening is 0.35mm;

[0026] S2. Hot-dip galvanizing the hardened steel plate, and the galvanizing requirement is 40g / ㎡;

[0027] S3. The steel plate after galvanizing is subjected to H-shaped single-sided pressing before winding up on the galvanizing line, thereby forming a pressed H-shaped pattern 3, and the depth of the pattern is 4 μm. The roller is a mirror flat roller, and the skinning liquid needs to be evenly sprayed on the lower roller, the pressing pressure is 250mpa, the pressing speed of the hot-dip galvanizing line is 120m / min, and the back of the hot-dip galvanized coil is flat and unchanged;

[0028] S4. The single-sided H-type hot-dip galvanized coil that has been pressed has been transferred to the c...

Embodiment 2

[0035] The present invention also provides a production process for single-sided H-shaped embossed PCM color-coated steel sheets, the specific steps of which are as follows:

[0036] S1, select the steel plate, the thickness of the steel plate after pickling and hardening is 0.6mm;

[0037] S2. Hot-dip galvanizing the hardened steel plate, and the galvanizing requirement is 60g / ㎡;

[0038] S3. The steel plate after galvanizing is subjected to H-shaped single-sided pressing before winding up on the galvanizing line, so as to form a pressed H-shaped pattern 3, and the depth of the pattern is 5 μm. The roller is a mirror flat roller, and the skinning liquid needs to be evenly sprayed on the lower roller, the pressing pressure is 280mpa, the pressing speed of the hot-dip galvanizing line is 140m / min, and the back of the hot-dip galvanized coil is flat and unchanged;

[0039] S4. The single-sided H-type hot-dip galvanized coil that has been pressed has been transferred to the colo...

Embodiment 3

[0046] The present invention also provides a production process for single-sided H-shaped embossed PCM color-coated steel sheets, the specific steps of which are as follows:

[0047] S1, select the steel plate, the thickness of the steel plate after pickling and hardening is 1mm;

[0048] S2. Hot-dip galvanizing the hardened steel plate, and the galvanizing requirement is 100g / ㎡;

[0049] S3. The steel plate after galvanizing is subjected to H-shaped single-sided pressing before winding on the galvanizing line, thereby forming a pressed H-shaped pattern 3, and the depth of the pattern is 7 μm. The upper roll used is a steel roll with engraved H-shaped texture, and the lower The roller is a mirror flat roller, and the skinning liquid needs to be evenly sprayed on the lower roller, the pressing pressure is 300mpa, the pressing speed of the hot-dip galvanizing line is 160m / min, and the back of the hot-dip galvanized coil is flat and unchanged;

[0050] S4. The single-sided H-typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap