Preparation technique and apparatus of waste plastic pyrolyzed oil and application of waste plastic pyrolyzed oil as diesel fuels

A preparation process and technology of waste plastics, applied in the fields of environmental protection and energy utilization, can solve the problems of no relevant reports on combustion performance analysis, and achieve the best engine performance and emission indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Example Preparation of plastic pyrolysis oil

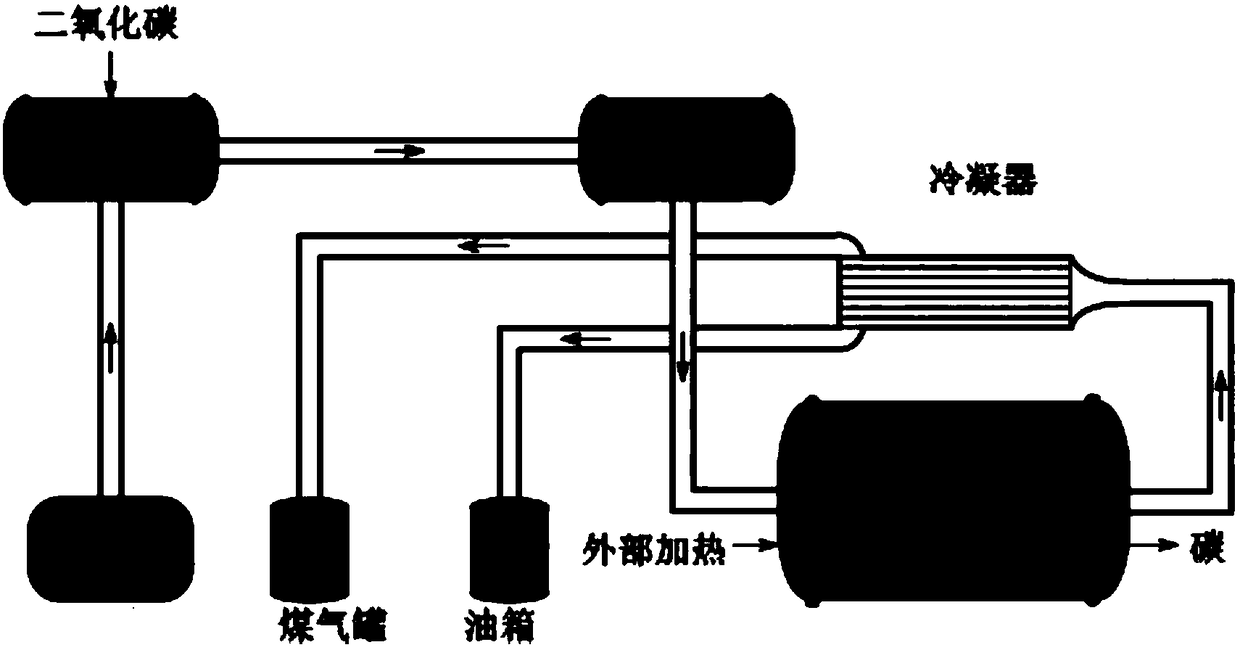

[0039] The specific process of preparing plastic pyrolysis oil is: firstly, the waste plastic raw material is broken into 1-2m 2 The small pieces are then transferred to the main chamber by a pump, and in the main chamber and the auxiliary chamber, the waste plastic pieces are replaced with carbon dioxide (CO 2 ) cleaning to ensure that there is no oxygen transfer to the conversion chamber; among them, using carbon dioxide (CO 2 ) because carbon dioxide is heavier than air, pushing air to the top of the chamber, and feedstock is transferred from the bottom of the chamber to the conversion chamber. The waste plastic block is converted into coke and gas by rapid pyrolysis in the conversion chamber with a temperature maintained at 900°C. One outlet of the conversion chamber collects recovered solids, including coke and / or part of the non-pyrolyzed waste plastic, and the other outlet is used for the gas phase The material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com