Combined system arranged on pressure-free concealed culvert and used for regulating and controlling suspension mass separation mode according to flow

A combination system and separation method technology, applied in the field of suspension mass separation system, can solve the problems of high investment, flooding and multiple safety of slopes, reduce the amount of support engineering, reduce engineering investment, and ensure safe operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

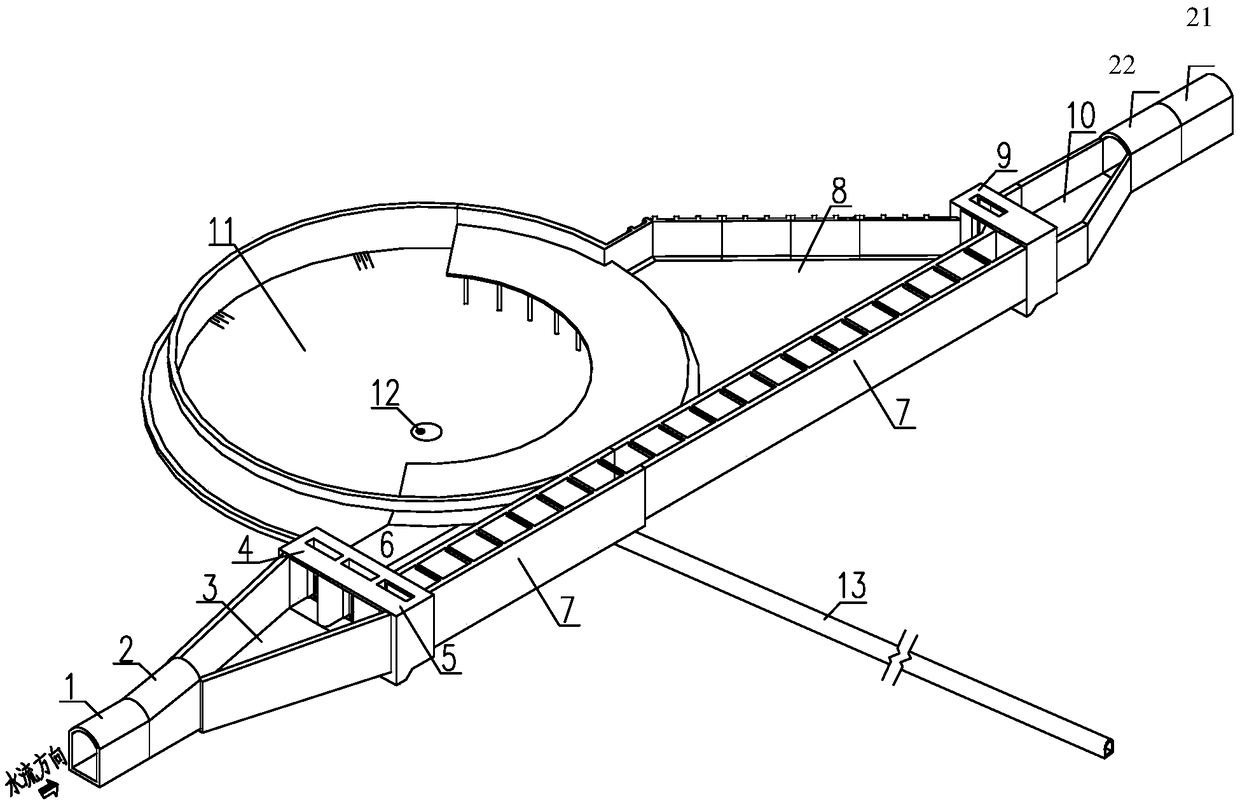

[0011] like figure 1 As shown, the combined system of the present invention, which is arranged on the non-pressure culvert according to flow regulation and suspended mass separation, includes an inlet section, an outlet section and a conical pool section, and an inlet section connected to the non-pressure culvert 1 at the entrance. Diffusion section 3 is arranged, after which the diffusion section is connected to inlet gate 4 and overflow gate 5, after inlet gate 4 is connected to water inlet hole 6, after overflow gate 5 is connected to flow channel 7; overflow pool 8 is arranged at the outlet section, and The overflow tank 8 is arranged side by side with the overflow channel 7, the control gate 9 arranged behind the overflow tank 8 and the overflow channel 7, the tapered section 10 is arranged behind the control gate 9, and the tapered section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com