Exhaust pipe fixing frame of rice harvester

A harvester and exhaust pipe technology, applied in the direction of harvesters, exhaust devices, cutters, etc., can solve the problems of loose exhaust pipes, short service life of exhaust pipe fixing frames, and insufficient fixation, so as to achieve not easy loosening. , The effect of preventing rust and corrosion and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

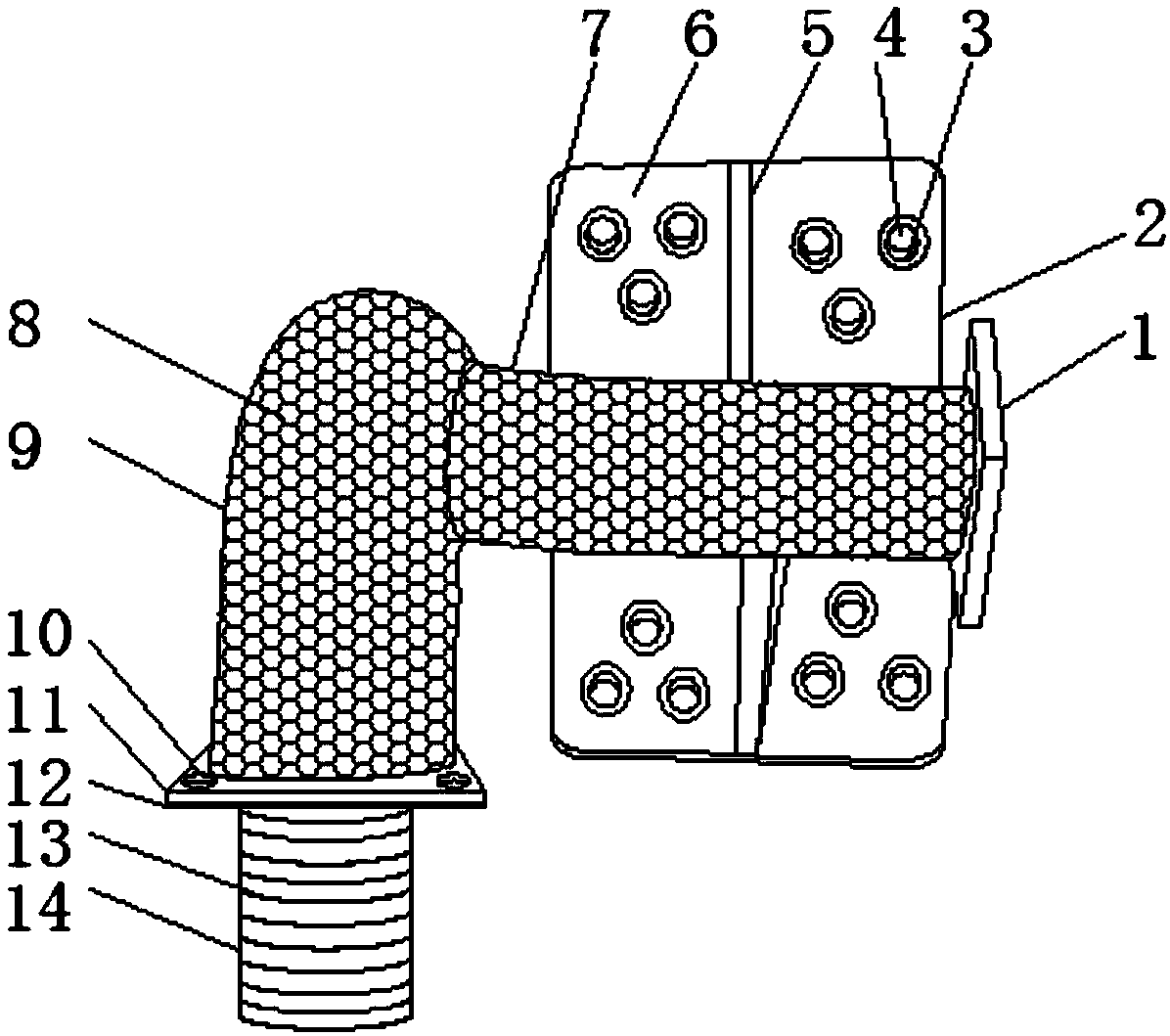

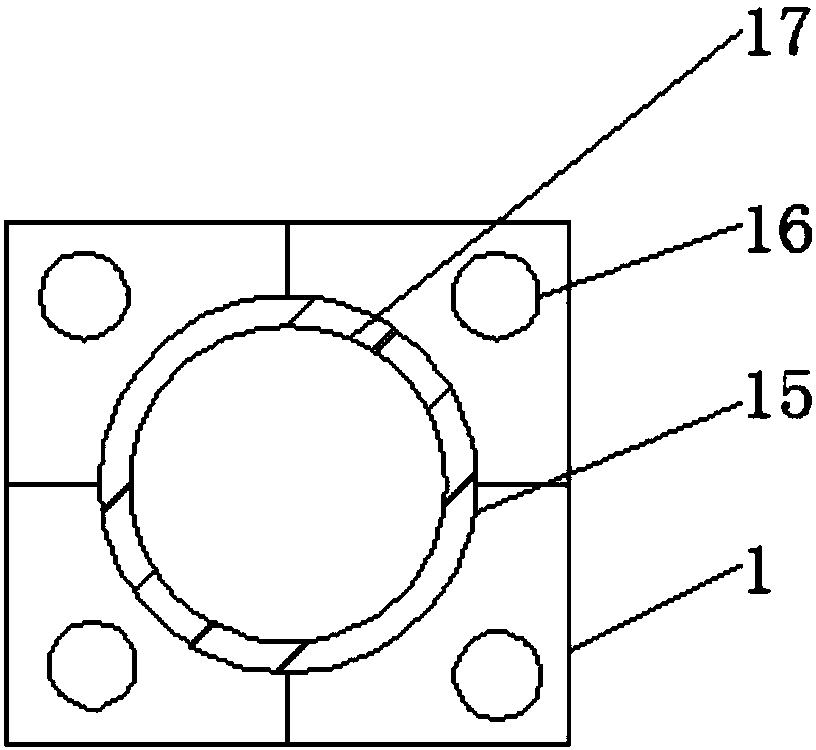

[0019] refer to Figure 1-2 , the exhaust pipe fixing frame of the rice harvester, including the mounting piece 1, the fixing piece 2, the connecting pipe 7, the connecting elbow 9 and the connecting piece 11, the connecting pipe 7 is welded on the surface of the mounting piece 1, and the connecting pipe 7 is welded on the lower surface The fixed piece 2, the surface of the fixed piece 2 is sprayed with anti-corrosion spray paint 6, the surface of the fixed piece 2 is connected with a strengthening connection structure 5, the surface of the fixed piece 2 is provided with a fixed nut groove 3, and the inside of the fixed nut groove 3 is provided with a fixed screw hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com