Tappet

A housing, stroke technology, applied in the direction of fuel injection pump, fuel injection device, mechanical equipment, etc., can solve the problems of no longer use, limited use, manufacturing and assembly limits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

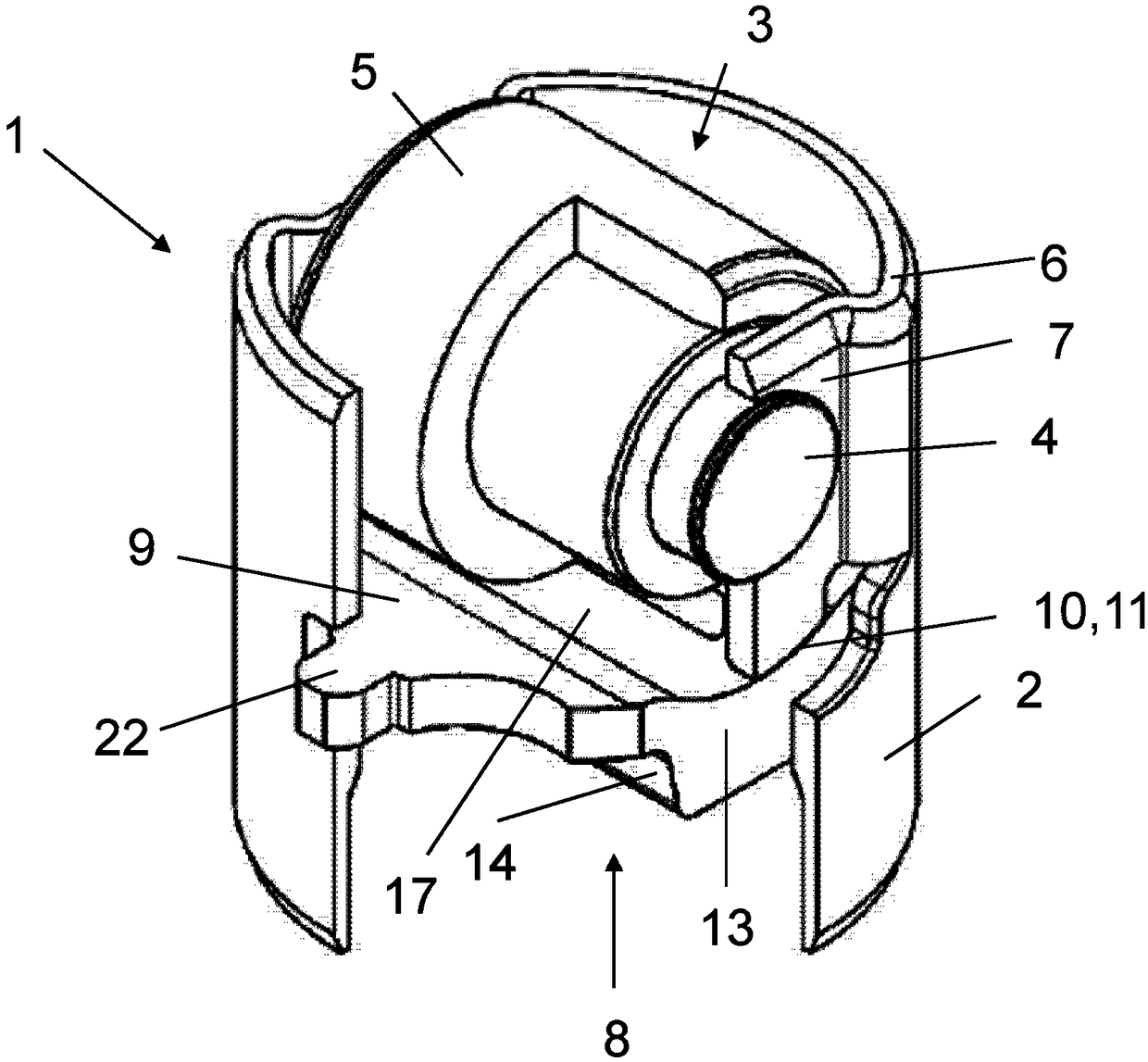

[0015] exist figure 1 , figure 2 shows a tappet 1 for a high-pressure injection pump or for a guide close to the pump for a high-pressure injection pump.

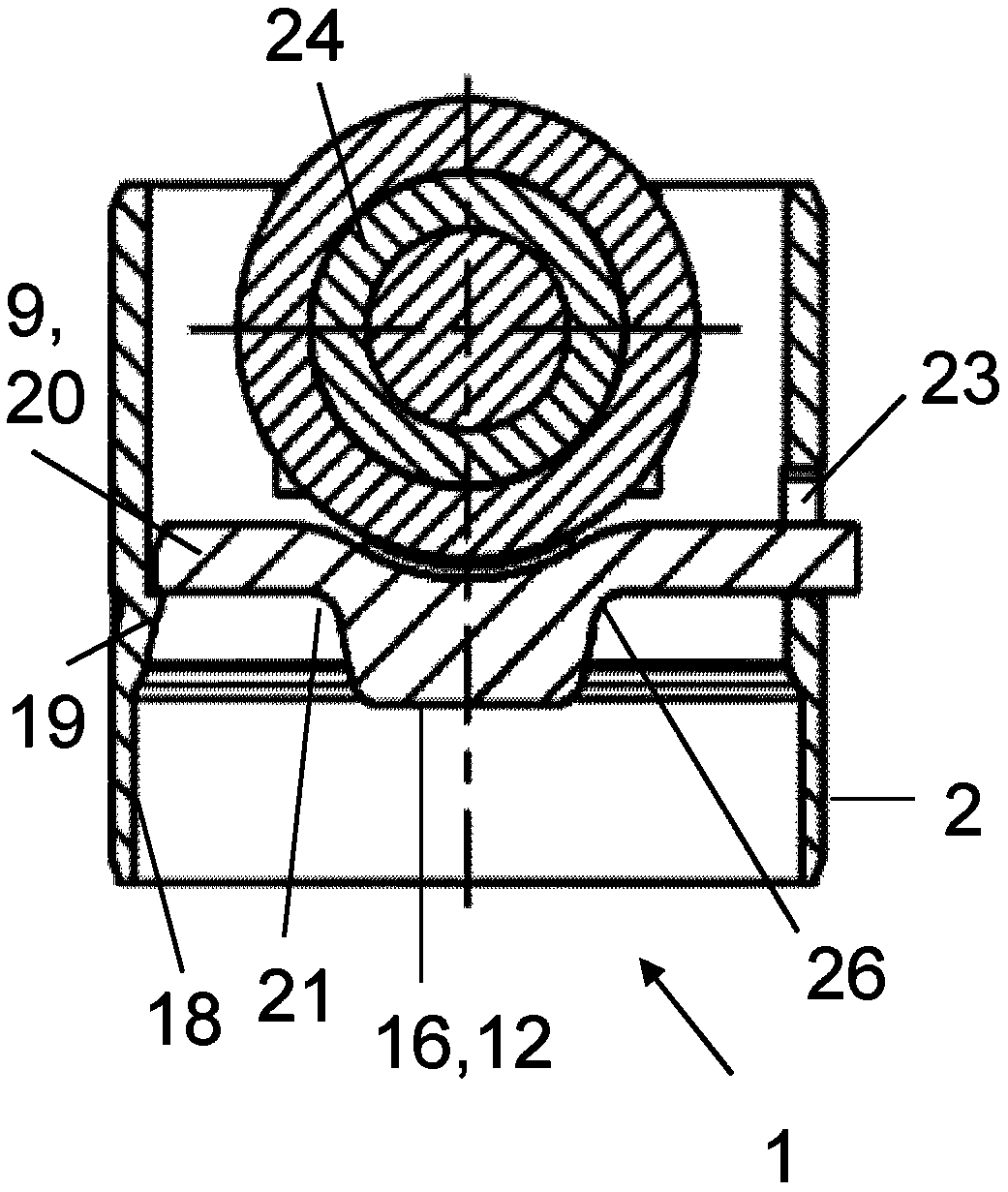

[0016] The tappet 1 has a substantially hollow cylindrical housing 2 made of sheet steel. Arranged on the drive side 3 of the housing 2 is a roller 5 for running the cam against which is supported on the pin 4 via an intermediate ring 24 . pin 4 as figure 1 The bearing is shown in two set-back flats 7 , which emerge from the drive-side end face 6 of the housing 2 .

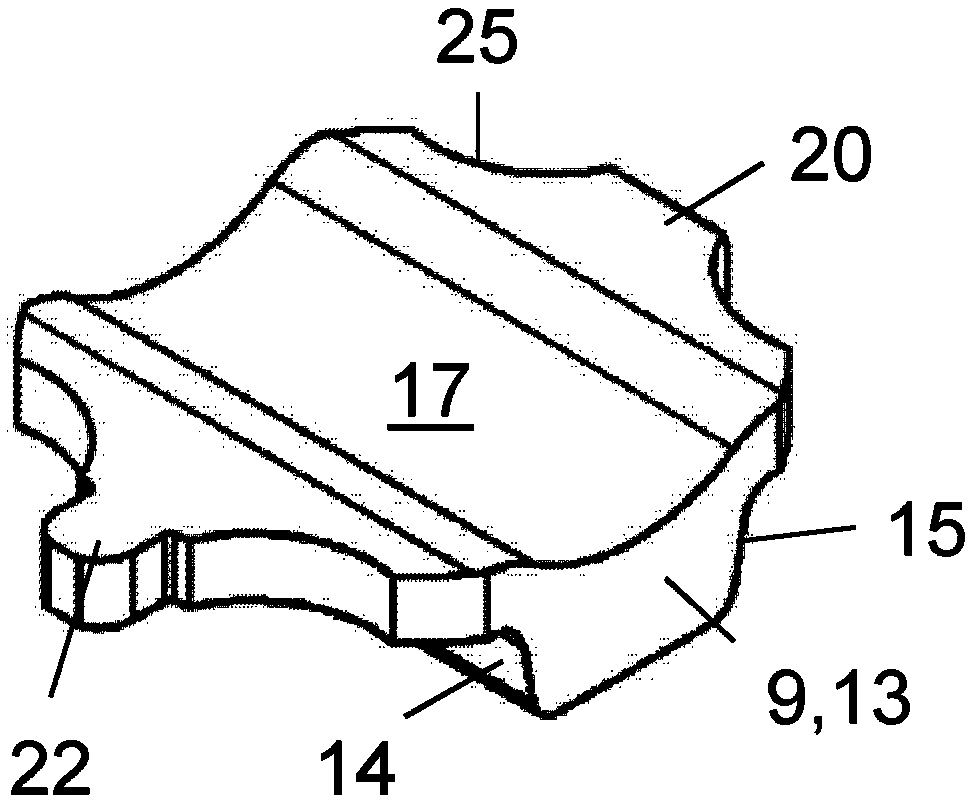

[0017] The output side 8 of the housing 2 is penetrated by a solid and free-standing plate 9 . If you can figure 1 As can be seen in , the plate 9 rests with its upper side 10 on the bowstring-shaped lower web 11 of the flat part 7 . The underside 12 of the plate 9 has a central abutment 16 for the pump piston.

[0018] What stands out is the solid construction of the plate 9 . In this case, it is separated from the semi-finished product like a profile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com