Preformed fitting installation tool of power transmission line

A technology for transmission lines and installation tools, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of long time-consuming, labor-intensive, and time-consuming, and achieve the effects of improving work efficiency, no damage to lines, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

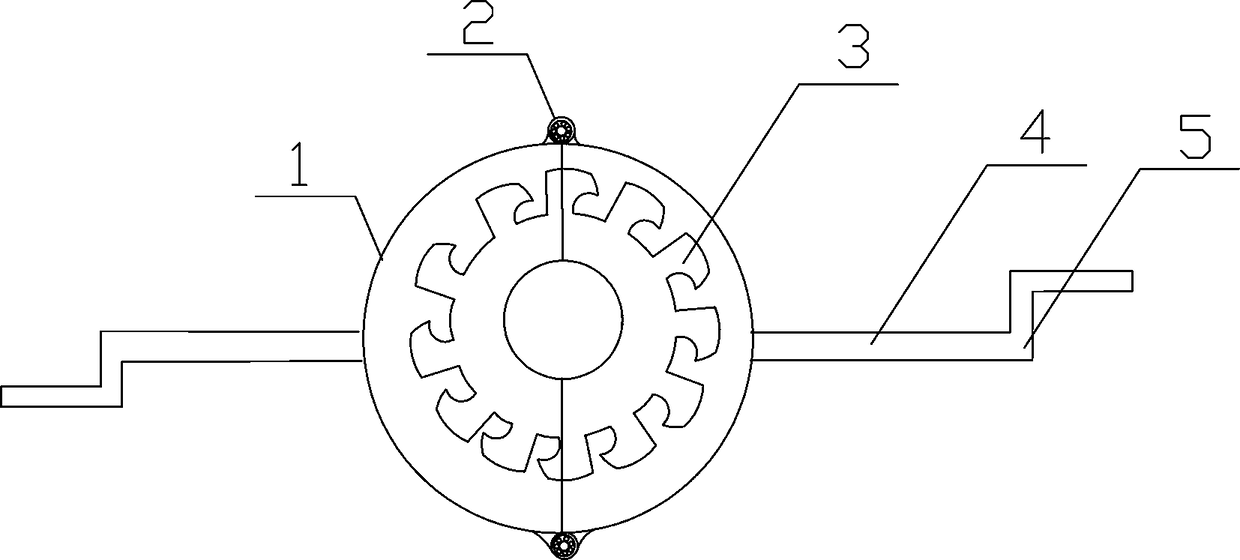

[0020] Such as figure 1 with figure 2 As shown, a power transmission line pre-twisted fitting installation tool includes two symmetrical semicircular clamps 1, the two clamps 1 are combined to form a circular clamp 1, and the joint of the two semicircular clamps 1 is provided with a joint Page 2, the center of the two clamps 1 together is a hollow circle, the inside of the clamp is provided with a slot 3, and the two semicircular clamps 1 are provided with connecting rods 4 on both sides, and the slot 3 is J type, the card slots 3 are uniformly arranged.

[0021] Preferably, the card slot 3 is a rubber card slot, and the clamp 1 is a stainless steel clamp.

[0022] Preferably, the number of three card slots in each clamp 1 is 5-8.

[0023] Preferably, the connecting rod 4 is provided with a handle 5, and the handle 5 is in the shape of a broken line.

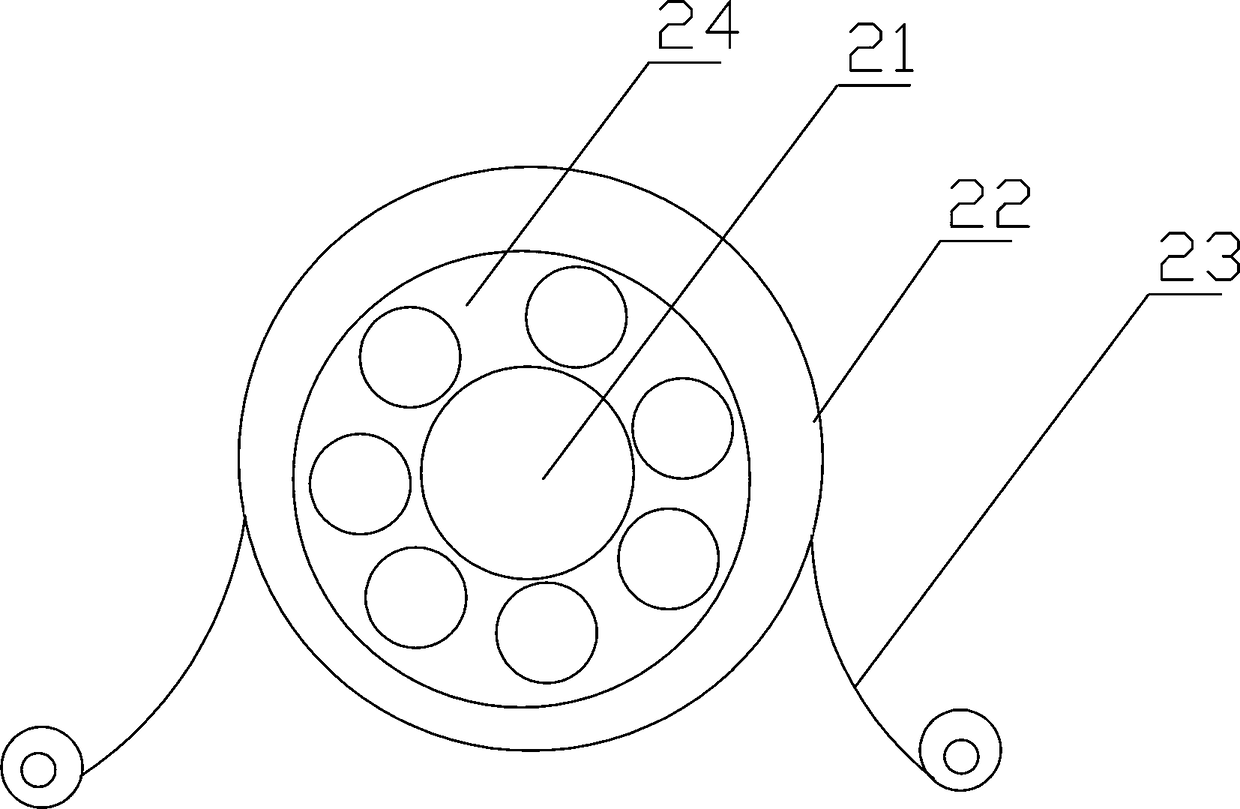

[0024] Preferably, the hinge 2 includes a mandrel 21 and two hinge pieces 23 sheathed on the mandrel 21 through a sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com