Novel DC motor commutator integrating EMC circuit

A DC motor and commutator technology, applied in electrical components, electromechanical devices, and electromagnetic interference suppression, etc., can solve the problems of complex product assembly process, complex product structure, and increase production costs, saving labor and material costs, and reducing assembly. process, the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

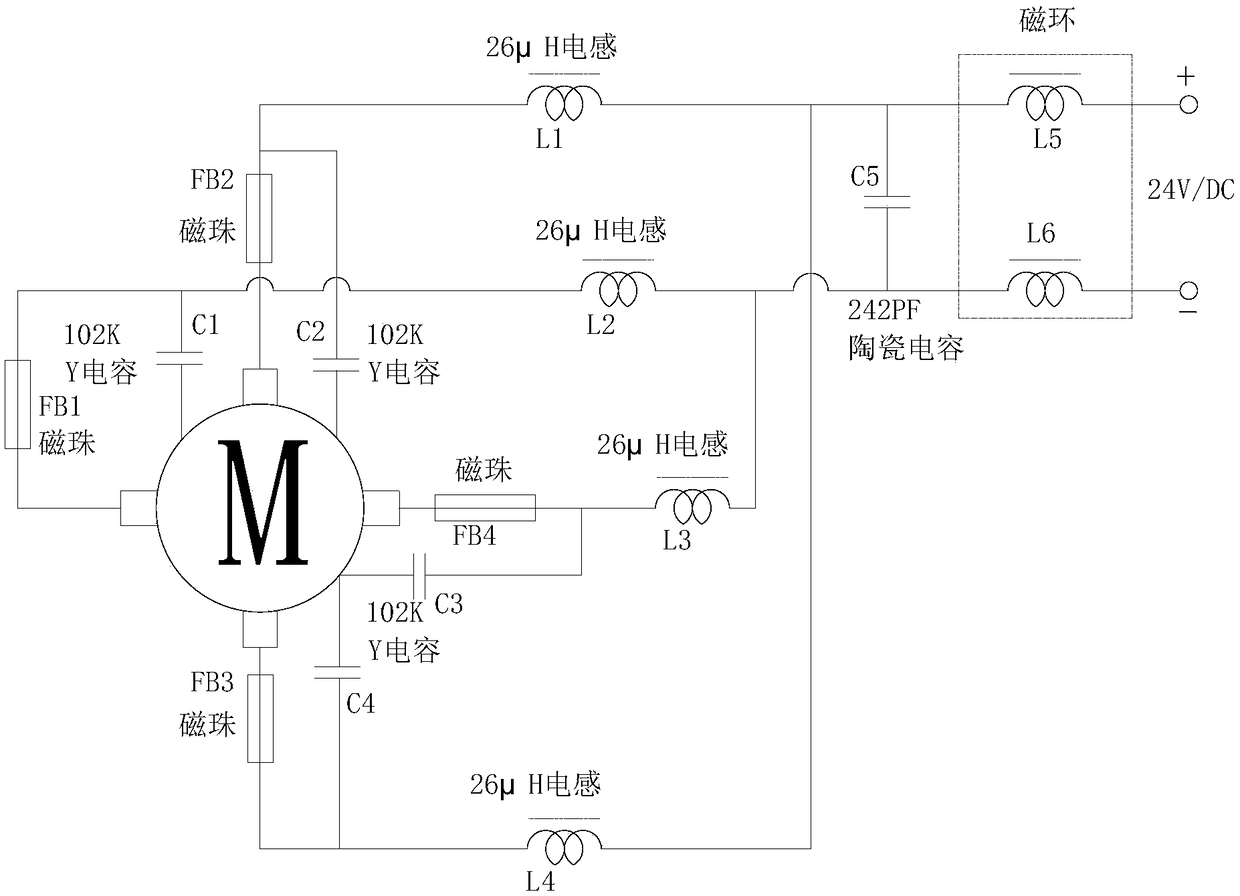

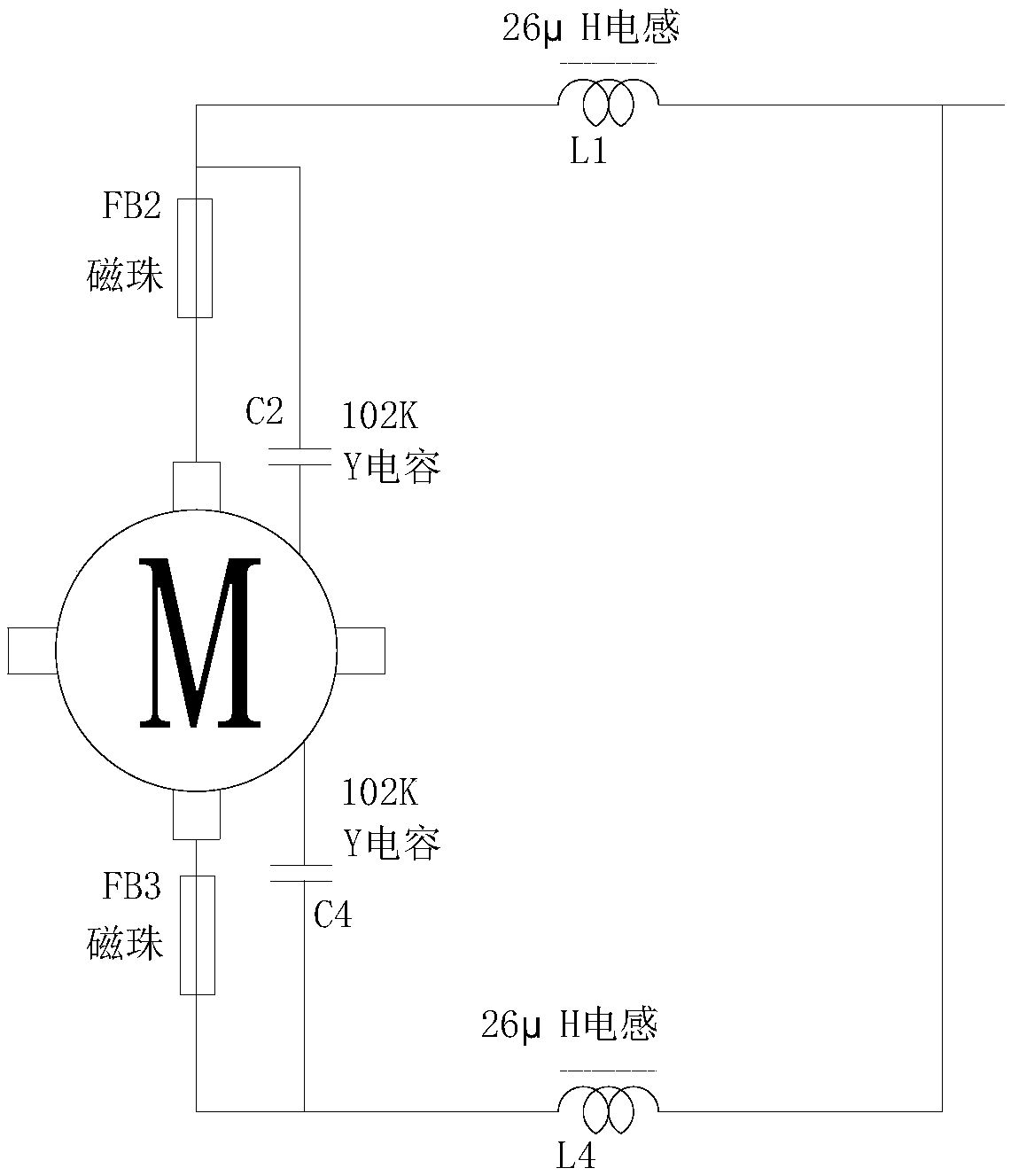

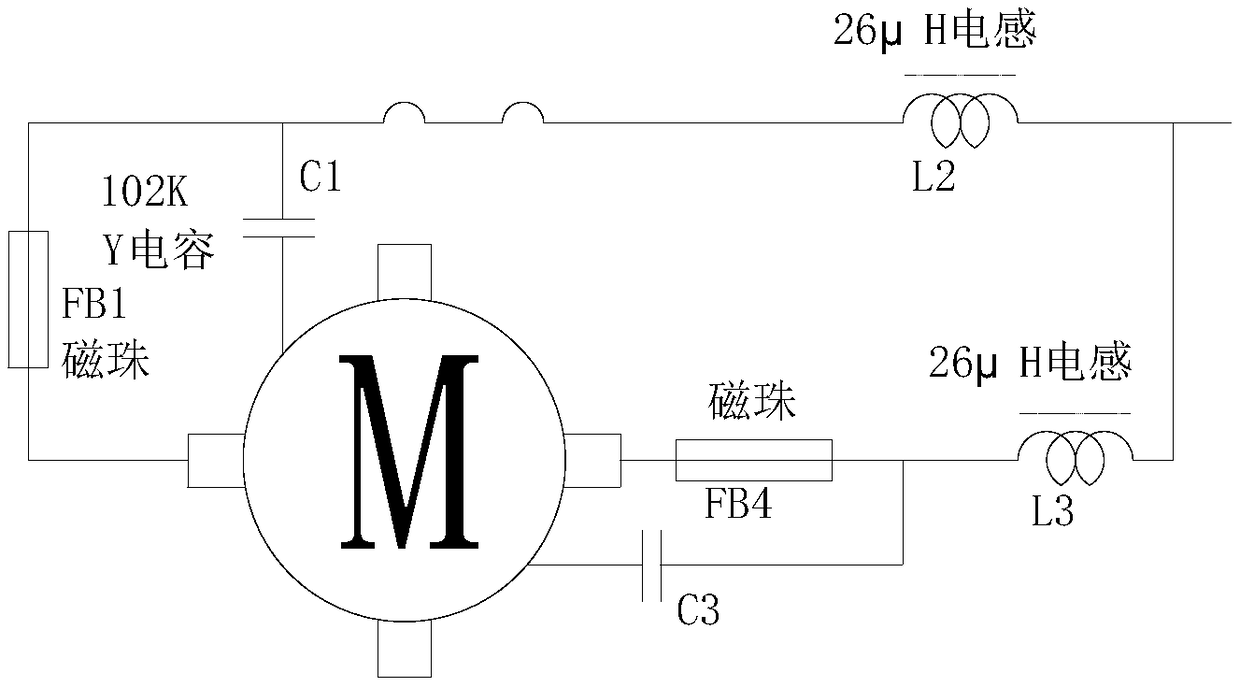

[0015] In this example, refer to figure 1 , figure 2 , image 3 and Figure 4 , the DC motor commutator of the novel integrated EMC circuit, its EMC circuit includes three parts, namely the positive pole working armature module, the negative pole working armature module and the comprehensive filter module, wherein the positive pole working armature module is connected to the positive pole of the motor M, and connected to the positive pole of the input power supply; the negative pole working armature module is connected to the negative pole of the motor commutator M and connected to the negative pole of the input power supply; the integrated filter module is set between the positive and negative poles of the input power supply; the positive pole working armature module includes a magnetic bead FB2 , magnetic bead FB3, capacitor C2, capacitor C4, inductance L1 and inductance L4, inductance L1 and inductance L4 are connected in parallel to the positive pole of the input power ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com