Paint dispersing equipment based on multidirectional acting force

A force and paint technology, applied in the direction of mixers, dissolvers, and mixers with rotating stirring devices, can solve the problems of limited dispersing effect of dispersing impellers, and achieve variable depth adjustment, improved dispersing effect, and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

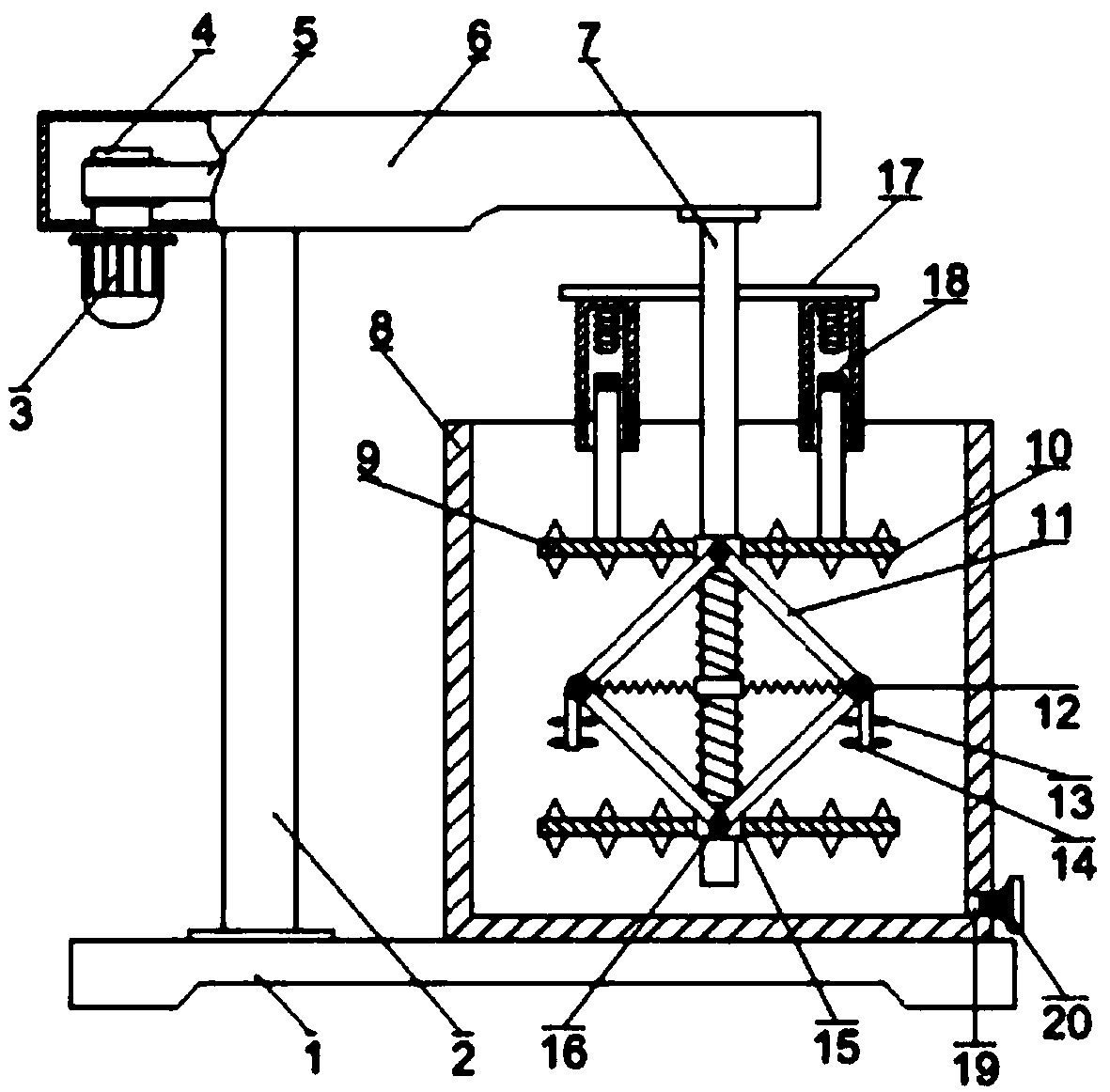

[0023] see Figure 1-Figure 2 , in the present embodiment, a kind of coating dispersing equipment based on multi-directional force, comprises base 1, and the left side of described base 1 is provided with support bar 2, and the top end of support bar 2 is provided with cantilever beam 6, and described The cantilever beam 6 is provided with a motor 3, a conveyor belt 5 and a pair of pulleys 4, one end of the conveyor belt 5 is connected with the motor 3 through the pulley 4, and the other end of the conveyor belt 5 is connected with a rotating shaft 7 through the pulley 4, and the rotating shaft 7 is located at In the dispersion bucket 8, the dispersion bucket 8 is located on the base 1, and the rotation of the motor 3 drives the pulley 4 to rotate, so that...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap