Transverse-moving-type stern anchor for main cable of cable crane

A traversing and traversing technology of the main cable of a crane, which is applied in construction, bridge construction, bridges, etc., can solve the problems of high safety risk, complex structure and operation, and achieve the effect of satisfying large tonnage and simplifying operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below with reference to accompanying drawing and embodiment:

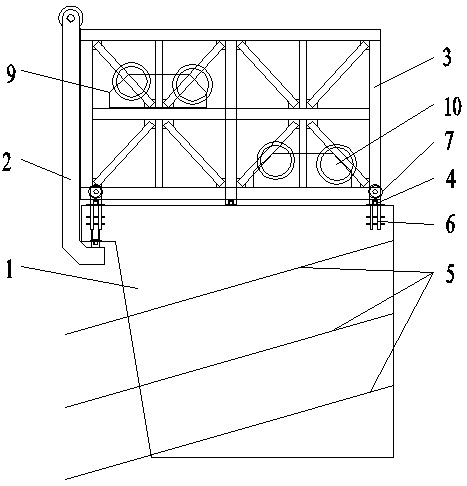

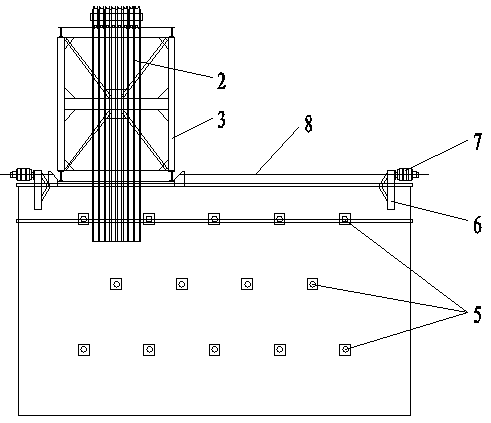

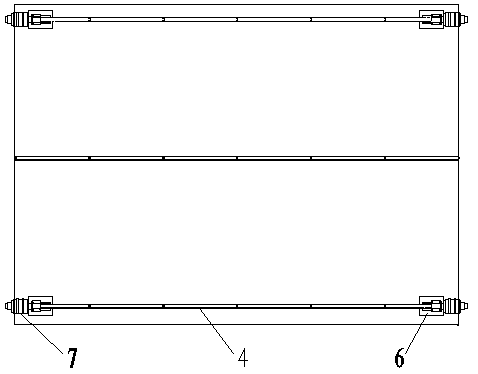

[0035] attached Figure 1-3 It can be known that a main cable traverse type rear anchor of a cable crane,

[0036] Including rear anchorage 1, main cable bearing frame 2, anchorage mechanical room 3, traverse slideway 4;

[0037] The main cable bearing frame 2 is set on the side of the rear anchorage 1 away from the mid-span of the bridge;

[0038] Anchor mechanical room 3 is arranged on the top surface of rear anchorage 1;

[0039] The main cable force frame 2 and the anchorage mechanical room 3 are fixed together by welding;

[0040] A traverse slideway 4 is set between the rear anchorage 1, the main cable bearing frame 2, and the anchorage mechanical room 3.

[0041] A total of four rows of traversing slideways 4 are arranged on the rear anchorage, among which three rows of traversing slideways 4 are arranged on the top surface of the rear anchorage 1, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drilling diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com