Wrapping composite fireproof structure for square steel tube concrete combined column

A technology of composite materials and composite columns, which is applied in fire protection, building structure, building components, etc., can solve the problems of unsatisfactory assembly of steel structure houses, unreliable installation and connection, and excessive thickness of fireproof boards, etc., to achieve simple structure, The effect of increasing the indoor use area and improving the fire resistance limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

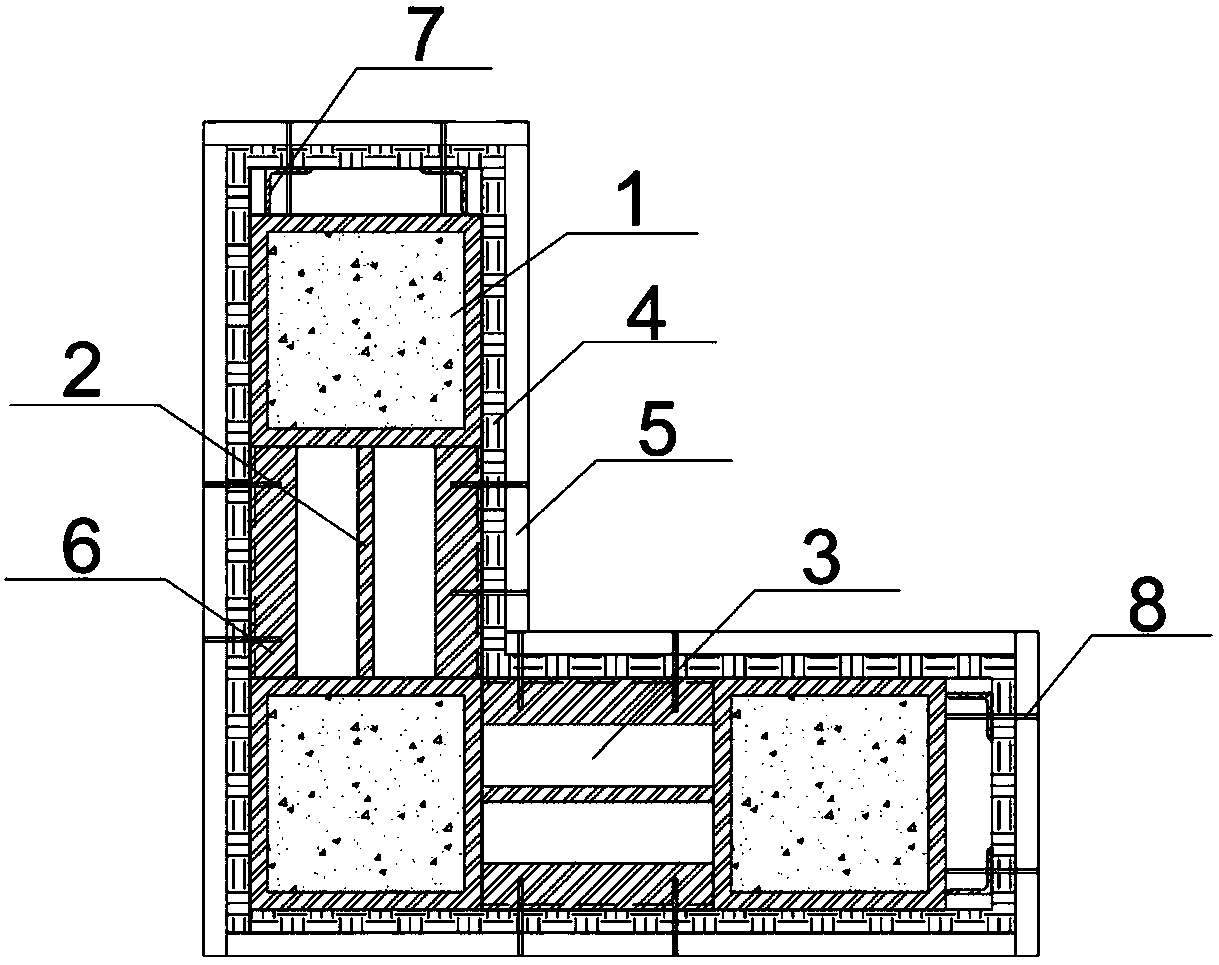

[0017] see figure 1 , a fire-proof structure of a square steel pipe concrete composite column outsourcing composite materials, including a flexible fire-proof inner layer 4 and a single-layer fire-proof board 5 arranged on its outer side, the single-layer fire-proof board 5 and the flexible fire-proof inner layer 4 are fixed on light On the steel keel, the light steel keel includes an inter-column light steel keel 6 and a column end light steel keel 7, and the inter-column light steel keel 6 is fixed between two adjacent column limbs 1 of the combined column. The side fixing surface of the fireproof layer formed by the light steel keel between the columns is flush with the side of the column limb 1 of the composite column, and the fixed surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com