An outsourcing anchor steel reinforcement structure suitable for concrete beam-column joints

A beam-column joint and reinforcement structure technology, applied in building construction, construction, building maintenance, etc., can solve problems such as brittle peeling damage of bonding interface, avoid peeling damage, improve shear bearing capacity and energy dissipation performance, The effect of improving the ductility of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

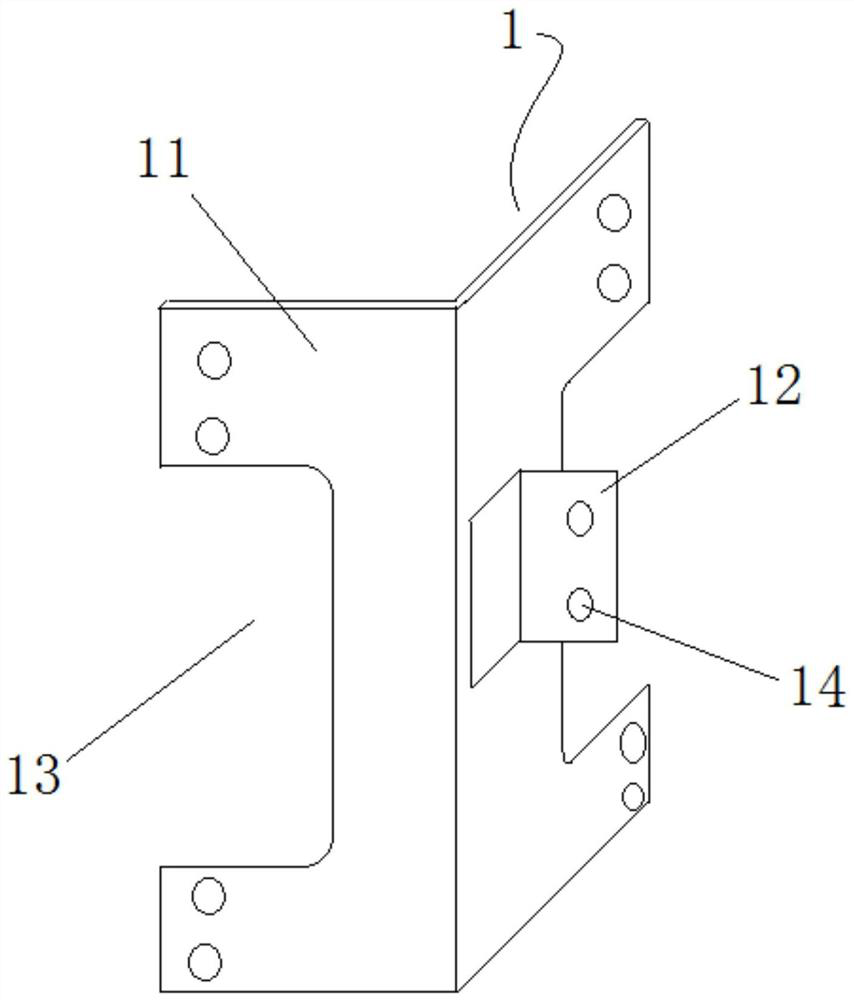

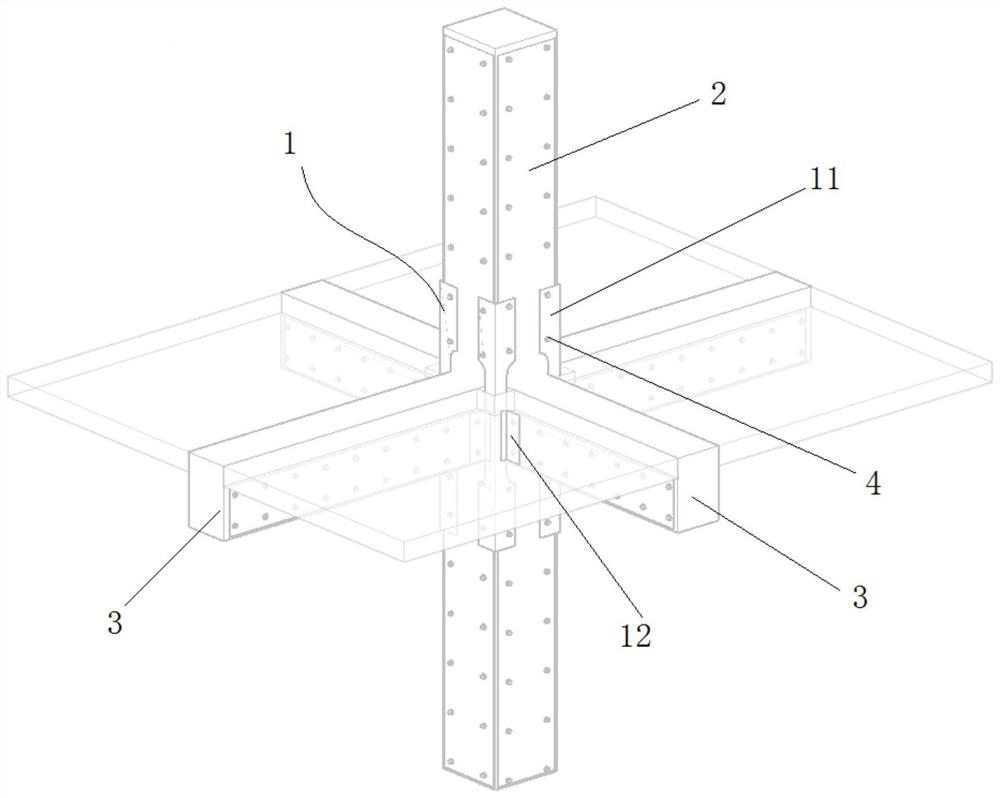

[0016] An outsourcing anchor steel reinforcement structure suitable for 3-column joints of concrete beams, its structure is as follows figure 1 , figure 2 As shown, the concrete beam 3-column joint includes a vertical concrete column 2 and a concrete beam 3 vertically connected to the concrete column 2 and horizontally arranged. The outer sides of the concrete column 2 and the concrete beam 3 are respectively wrapped with column-side steel plates and beam-side steel plates. The reinforcement structure includes four reinforcement units 1, and the structure of each reinforcement unit 1 is as follows figure 1 As shown, it includes a vertically set through angle steel 11 and beam side angle steel 12 fixed on the through angle steel 11, corresponding to the 1 / 2 height of the beam side steel plate. During installation, each through angle steel 11 is fixedly installed on the concrete column 2, the beam side angle steel 12 is fixedly connected with the concrete beam 3.

[0017] A U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com