Optical pickup device

An optical pickup and optical element technology, which is applied in the manufacture of beam guiding devices, instruments, optical heads, etc., can solve the problems of decreased bonding strength, low elastic modulus, unsuitable for optical elements, etc., and achieves high position accuracy, bonding Effects that do not drop in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

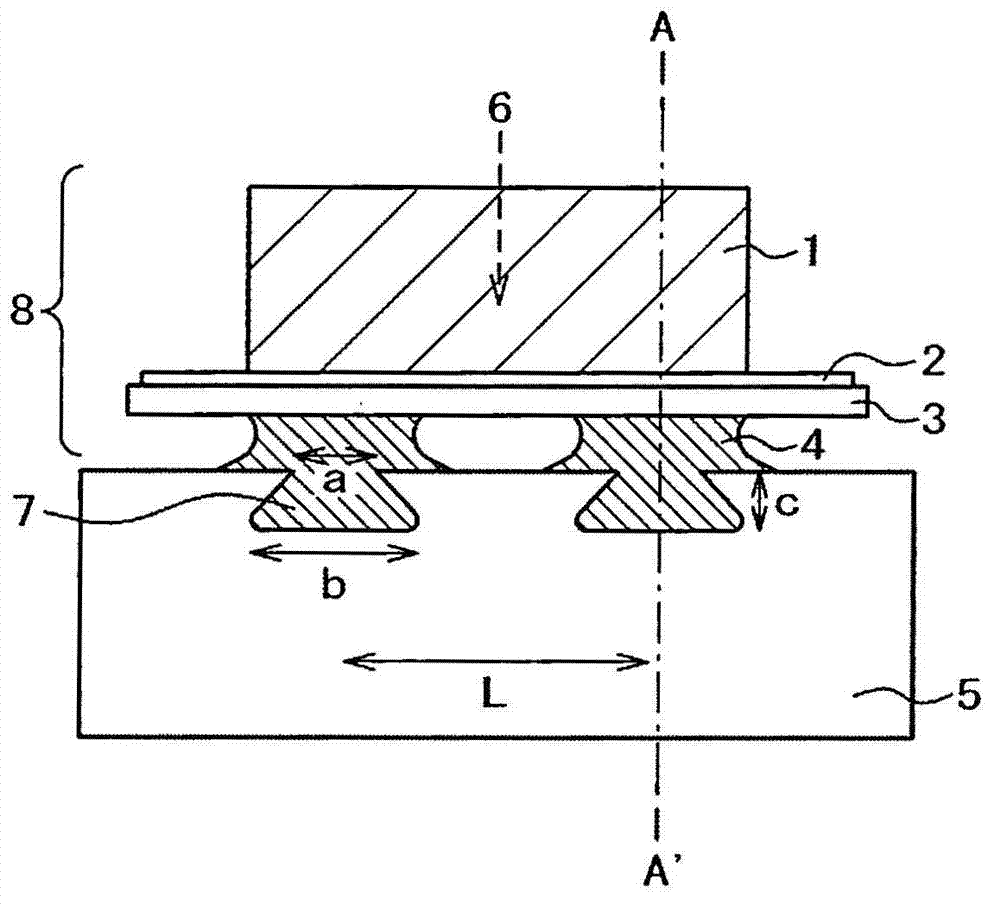

[0027] use Figure 1 ~ Figure 4 A first embodiment of the present invention will be described. First, use Figure 4 The configuration of the optical pickup device will be described. In addition, in this embodiment, the light-receiving element is used as an example for description, but it can also be applied to other light elements such as light-emitting elements. Figure 4 It is a schematic overall configuration diagram when optical components that function as optical lenses, such as an optical component unit 8 , a grating lens 11 , a coupling lens 12 , and a detection lens 13 , are bonded and fixed to the optical pickup case 5 . The optical component assembly 8 and various lenses move in the direction of the arrow in the downward direction, and are arranged at a prescribed position with respect to the optical axis of the optical pickup box 5. 8, the front or back side parallel to the optical axis is bonded and fixed. In addition, reference numeral 100 represents the confi...

Embodiment 2

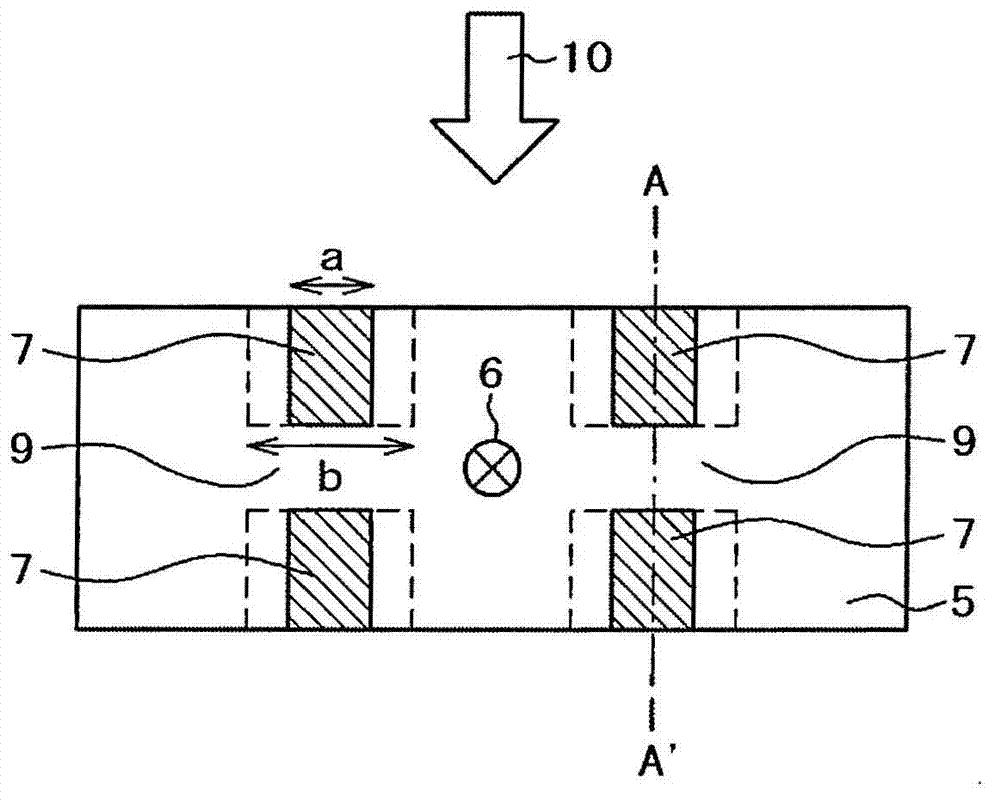

[0042] use Figure 5 (a), (b) The 2nd Example is demonstrated. In addition, matters described in the first embodiment but not described in the present embodiment can also be applied to the present embodiment unless otherwise specified. Figure 5 (a) and (b) are plan views of the bonding portion between the optical component unit 8 and the optical pickup case 5 in the optical pickup device of the present embodiment. The optical component unit is composed of a flexible printed circuit board 2 connected to the light receiving element 1 and a reinforcing plate 3 supporting the flexible printed circuit board 2 .

[0043] In the groove portion on the side of the optical pickup box, the relationship between the opening length a of the groove portion 7 and the longest length b inside the groove is a bonding structure of a

Embodiment 3

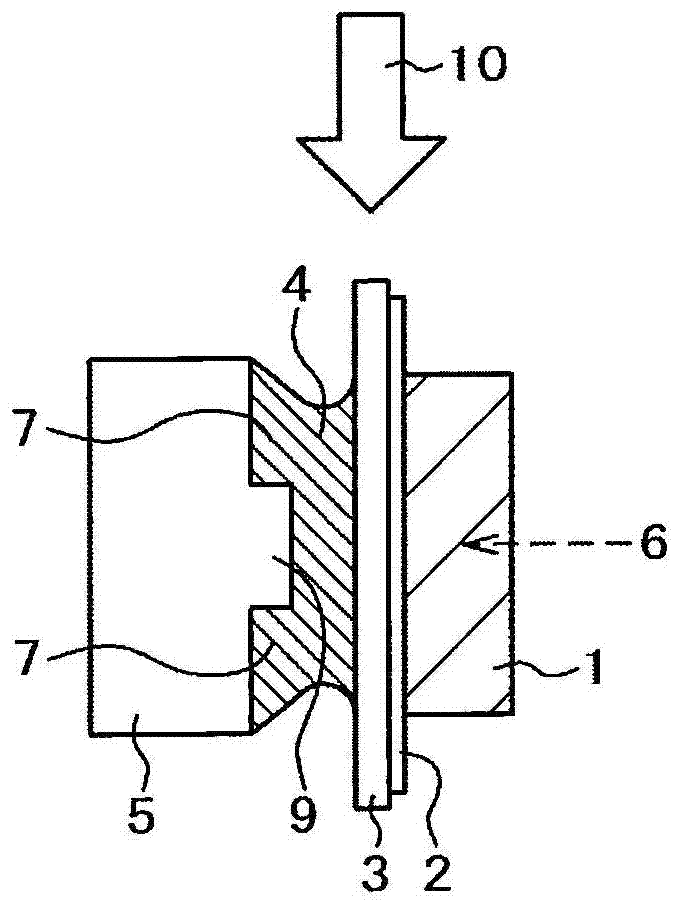

[0048] use Figure 6 (a), (b) The third embodiment will be described. In addition, matters described in Embodiment 1 or Embodiment 2 but not described in this embodiment can be applied to this embodiment unless otherwise specified. Figure 6 (a) and (b) are side views of the optical pickup case of the optical pickup device of this embodiment. Figure 6 (a) is an example in which, when bonding the back surface of the optical component unit, one groove portion is used as the bonding and fixing portion.

[0049] Figure 6 (b) In the case of bonding the back of the optical component unit, two grooves are provided as bonding and fixing parts, one groove for the optical pickup box is provided on the upper and lower sides, and the arrangement is arranged. An example of a sawtooth structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com