Reinforced film for flexible printing circuit board

A flexible printing and reinforcing film technology, applied in the direction of printed circuits, printed circuit components, and electrical components to assemble printed circuits, which can solve problems such as rising prices, difficulty in manufacturing, and warping, and achieve the effect of inhibiting interface peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

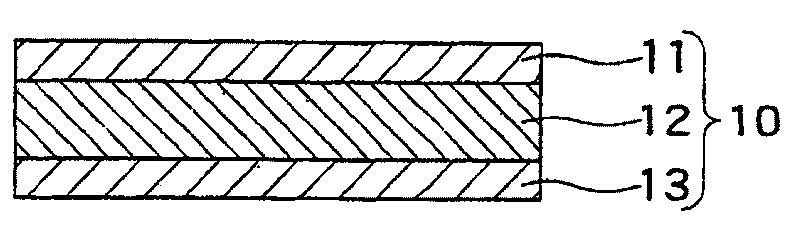

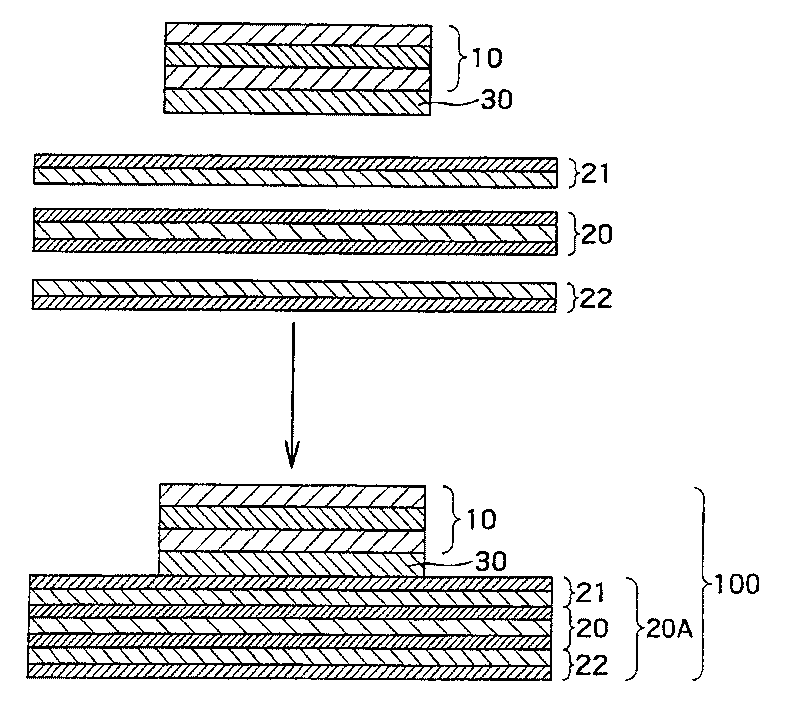

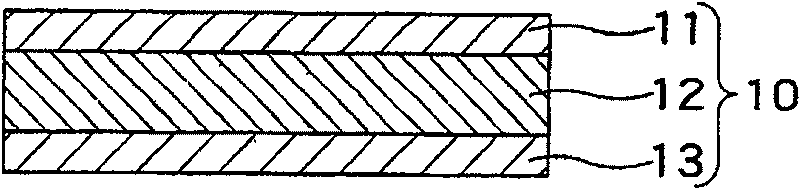

[0020] figure 1 A cross-sectional structure of a heat-resistant film having a three-layer structure as Example 1 of the present invention is shown. The water vapor transmission coefficient of the heat-resistant resin film of the present invention is adjusted by mixing air bubbles into the film itself. The value of the water vapor transmission coefficient is considered to be about 30.0g / 24h·m2.

[0021] When the water vapor transmission coefficient is extremely low, water vapor does not pass through the reinforcement film but stays between the interface between the reinforcement film and the flexible printed circuit board due to a high temperature process such as a reflow process, causing interfacial peeling. The heat-resistant resin film with adjusted water vapor transmission coefficient is obtained by casting and coating a heat-resistant resin solution in which water vapor is mixed by stirring, followed by heating and drying. The produced film thickness is usually 12.5 to 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com