Fall difference type hydroelectric equipment

A power generation equipment and water conservancy technology, which is applied in the field of drop-type hydropower generation equipment, can solve the problems of large power consumption and high cost of pulling wires, and achieve the effect of reducing additional wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

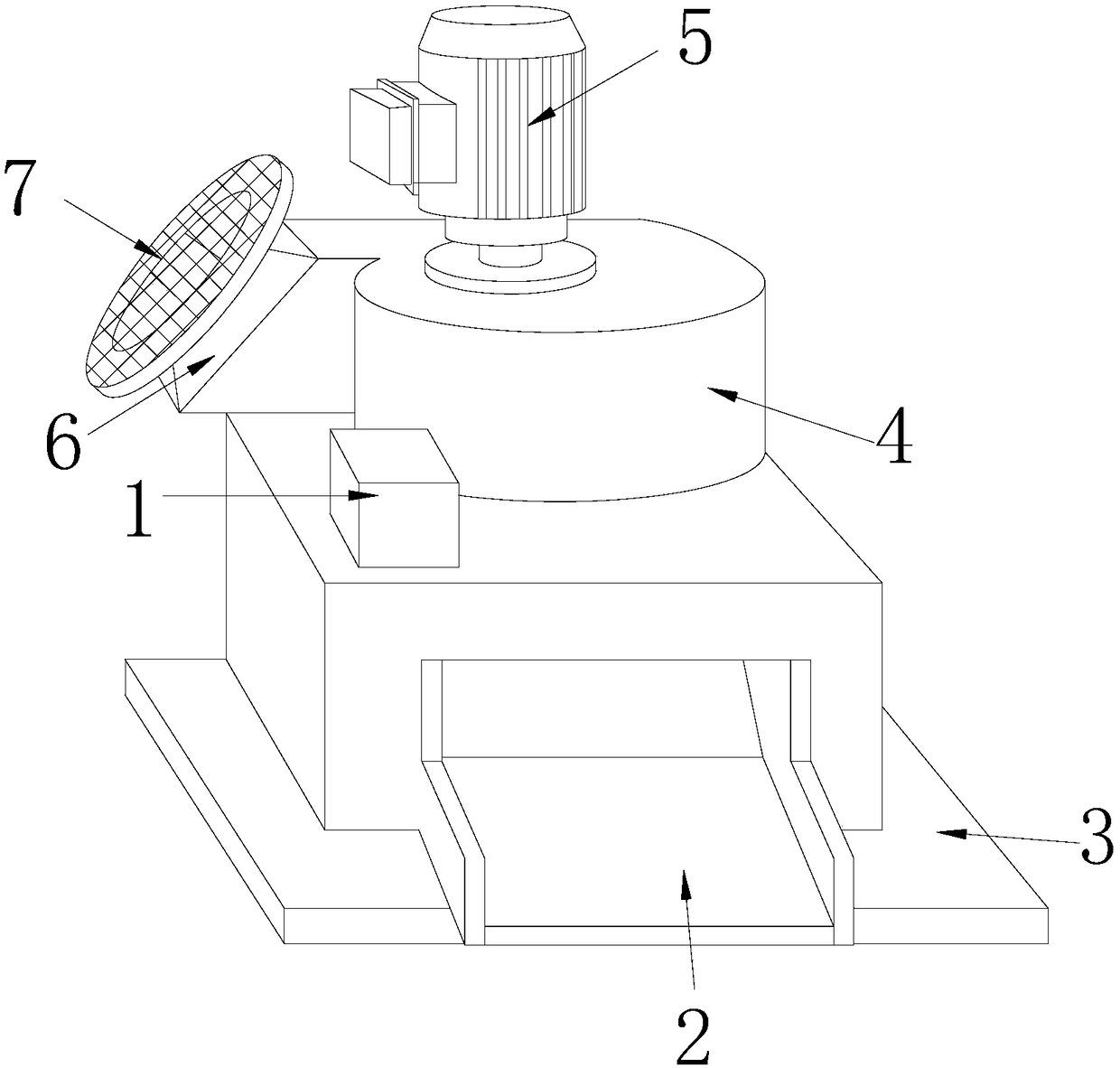

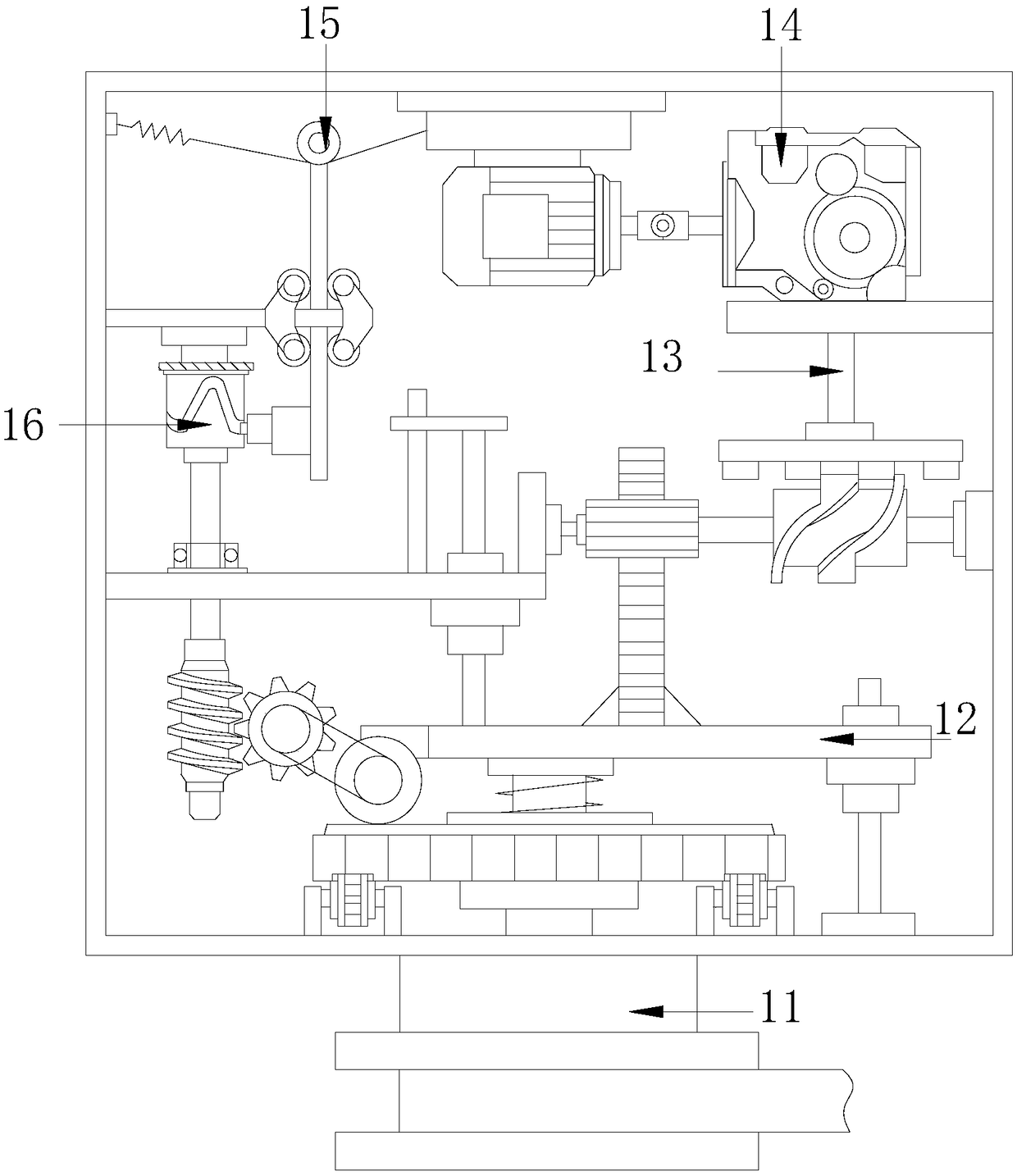

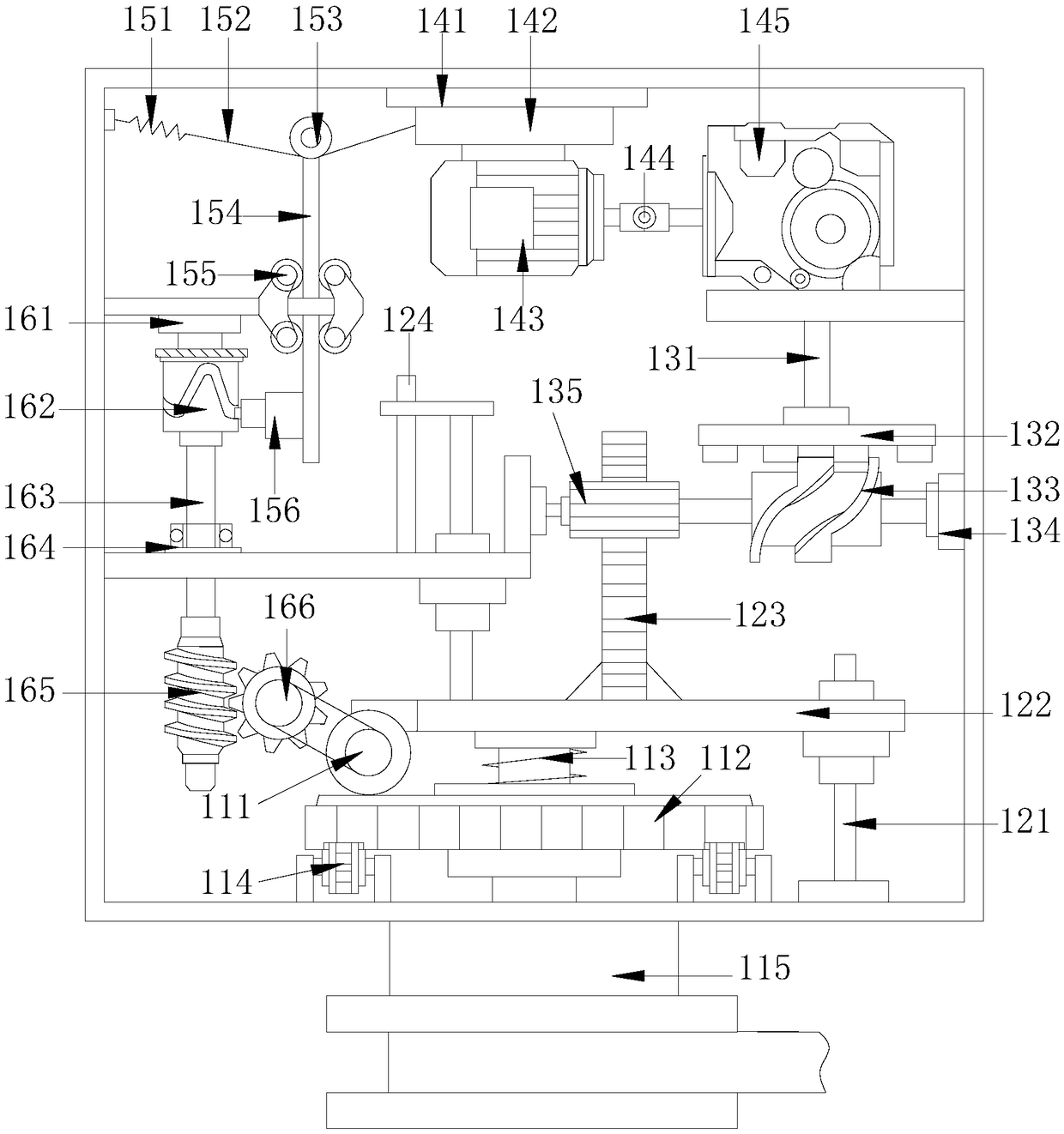

[0020] like Figure 1-Figure 4 As shown, the present invention provides a drop-type hydroelectric power generation equipment, the structure of which includes: a voltage regulator 1, a water flow chamber 2, a base 3, a turbine box 4, a generator 5, a water inlet bucket 6, and a filter screen 7. The bottom of the voltage regulator 1 is fixed on the top of the casing of the water flow chamber 2 by bolts, the water flow chamber 2 is welded and fixed on the top of the base 3 horizontally, and the impeller inside the turbine box 4 is installed on the bottom of the generator 5 , and closely fit with the voltage regulator 1, the water inlet bucket 6 is in interference fit with the filter screen 7 on the top, the water inlet bucket 6 is welded and fixed on the front end of the square groove of the water flow cavity 2, the voltage regulator The device 1 is provided with a detection pulley 11, a movable pressing plate 12, a rotating tooth column 13, a pressing driving device 14, a detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com