Manufacturing method of novel composite thermal column

A manufacturing method and heat column technology, applied in indirect heat exchangers, lighting and heating equipment, cooling/heating devices of lighting devices, etc., can solve problems such as leakage, and achieve normal operation, small thermal resistance, and low startup The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. All other embodiments obtained by ordinary persons in the art without creative efforts belong to the protection scope of the present invention.

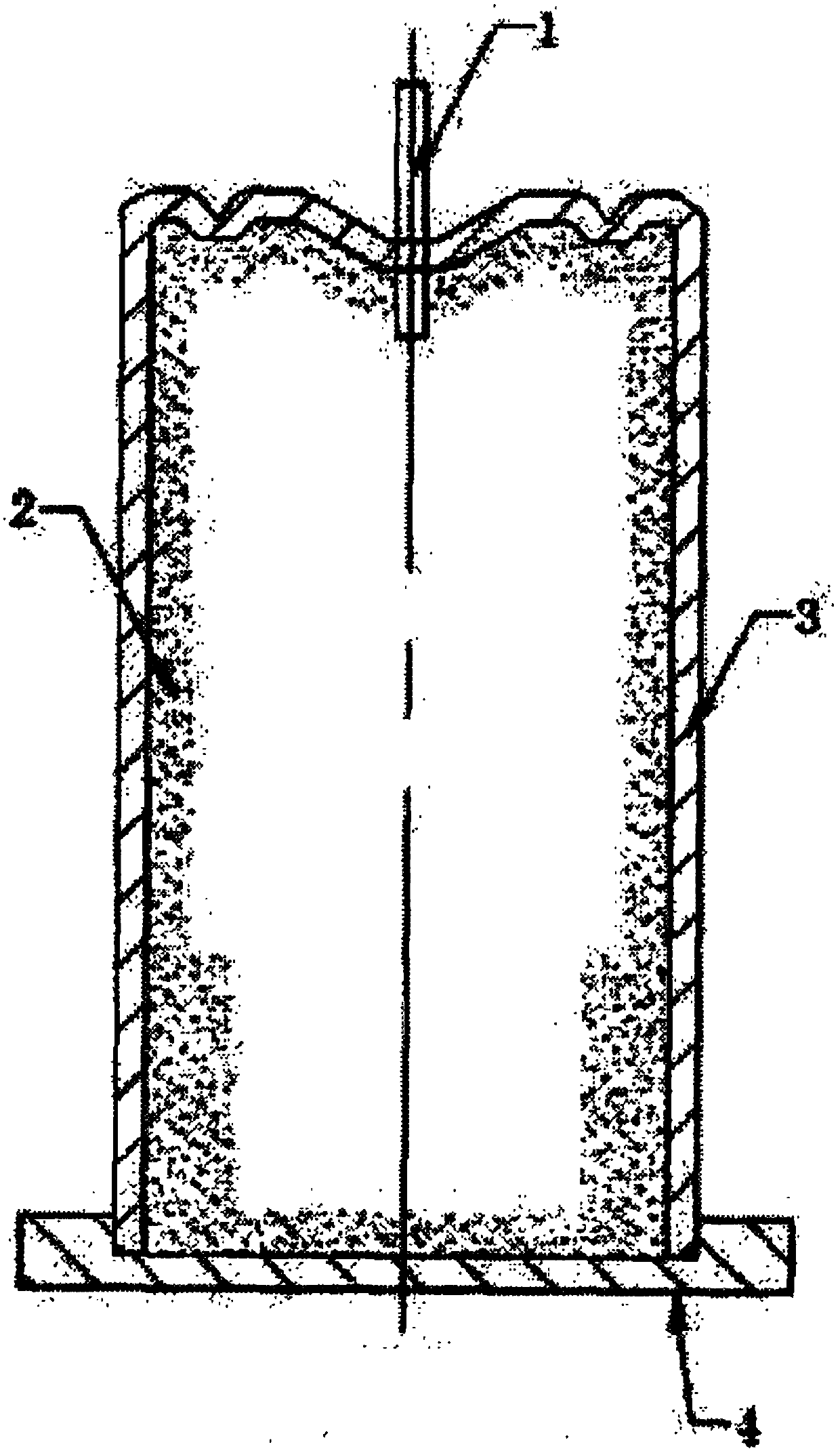

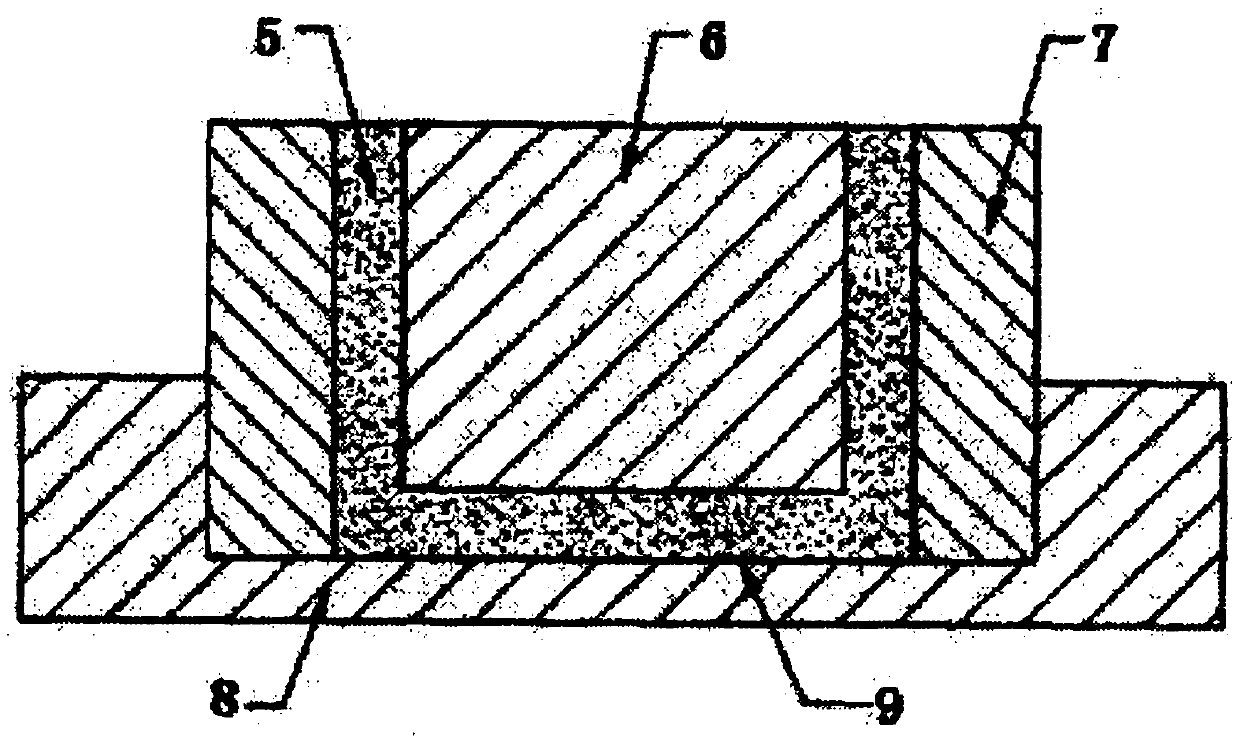

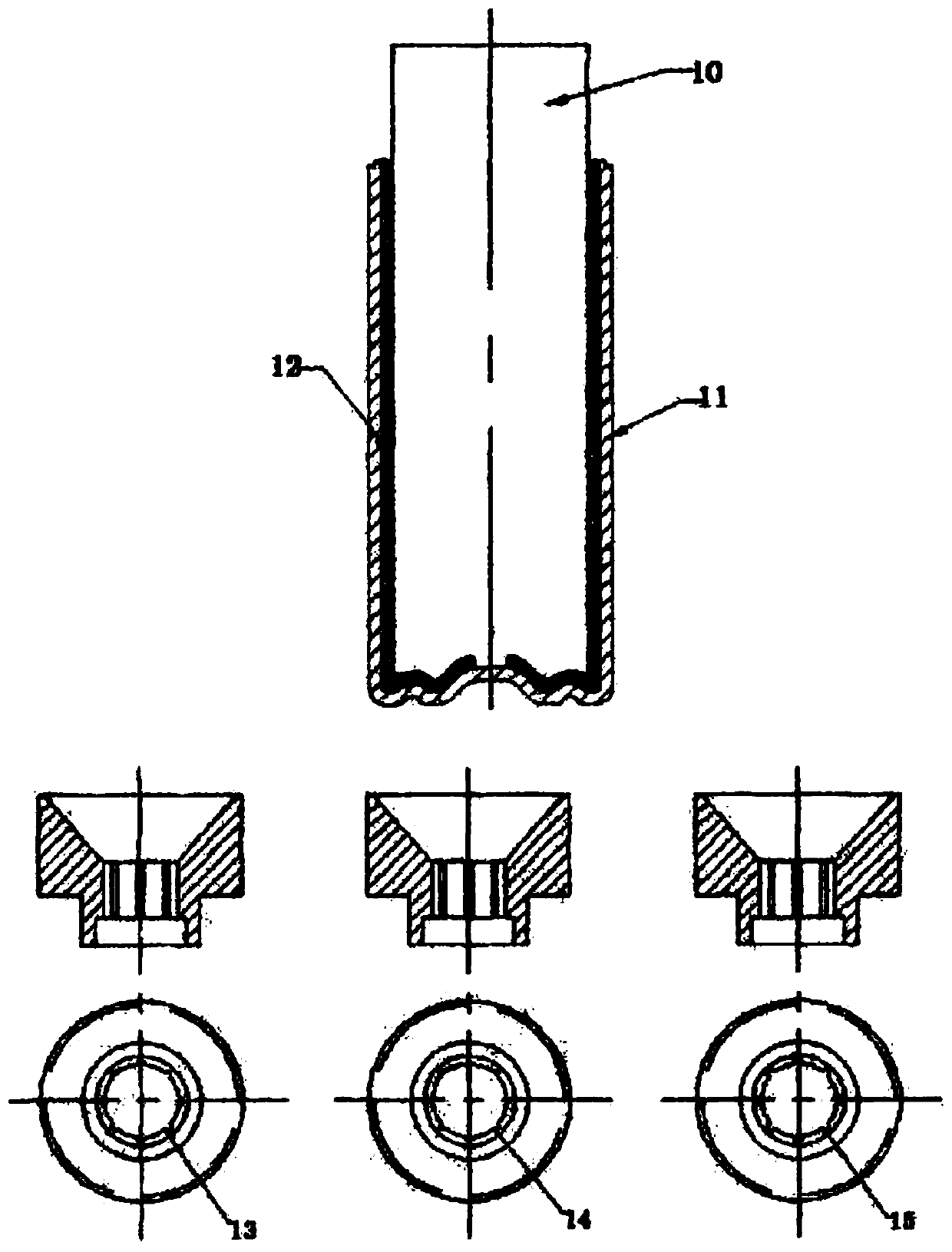

[0063] The method of assembling and welding hot column sintering is decomposed into sub-item sintering, assembly and then brazing. The thermal column body is put into the mandrel, and the electrolytic copper powder is vibrated into the interlayer through a special funnel for sintering. The evaporation section of the bottom plate is used The fixture is positioned and sintered to form a sintered copper powder layer that meets the required shape. The heat column body 2 is assembled with the base plate 1, so that the sintered layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com