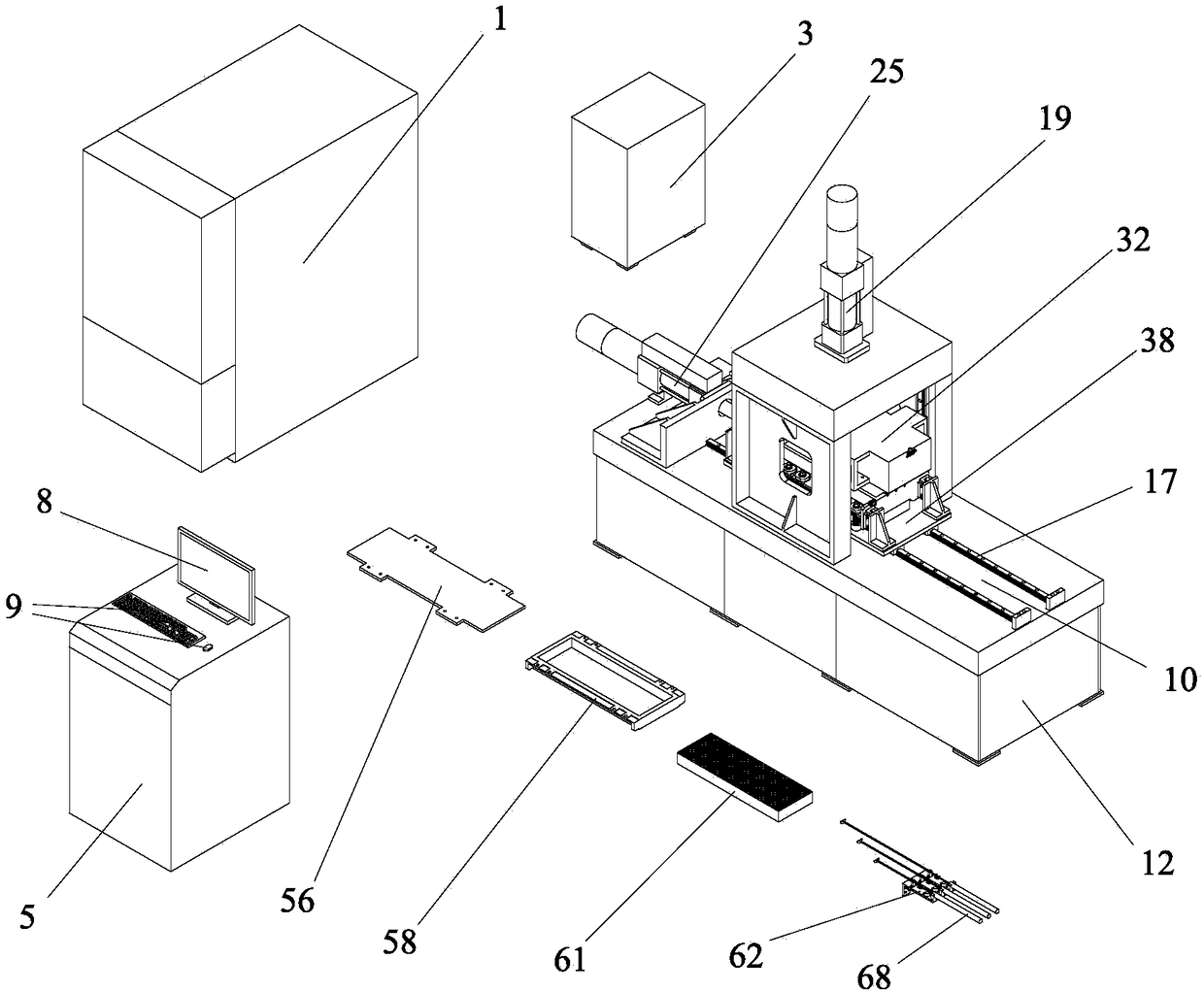

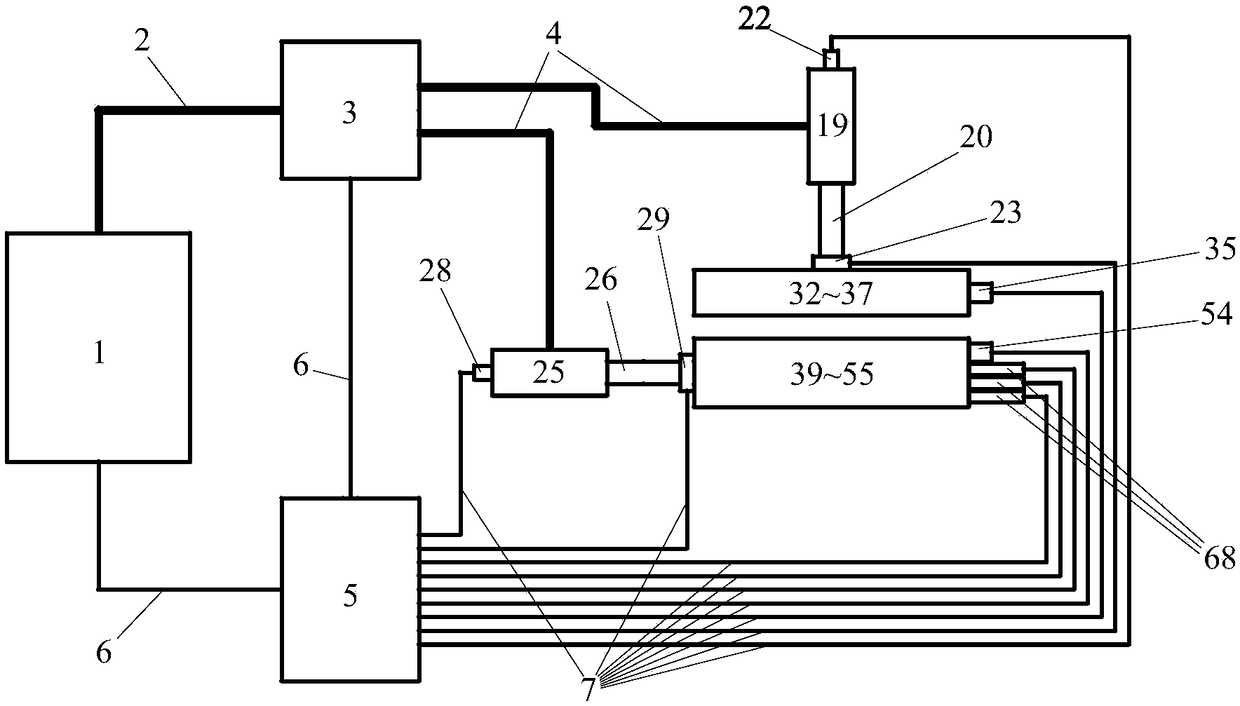

Large-size multifunctional interface dynamic shear tester and test method

A shear test and multi-functional technology, applied in the direction of applying stable shear force to test the strength of materials, instruments, scientific instruments, etc., can solve the problems of difficult research work and lack of test instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

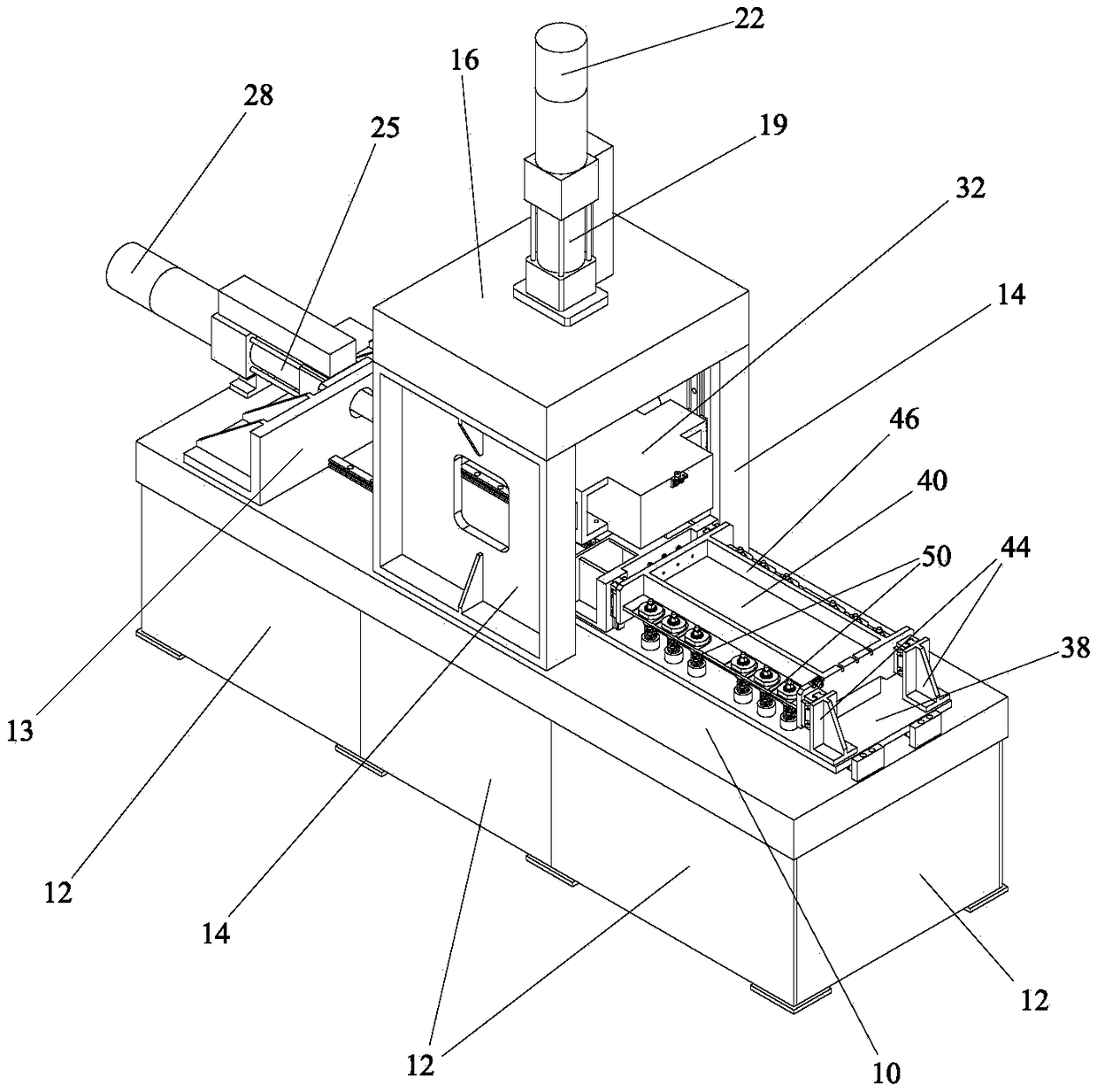

[0086] Embodiment 1: Geomembrane-GCL interface dynamic shear test

[0087] Based on the large-scale multifunctional interface dynamic shear tester proposed by the present invention, the working process of carrying out the geomembrane-GCL interface dynamic shear test is mainly divided into three stages: test preparation stage, test progress stage, and test end stage.

[0088] Test preparation stage: First, cut and prepare geomembrane sample 69 and GCL sample 70 according to the size of the upper and lower shear boxes, wherein the size of GCL sample 70 is consistent with the size of the shear box, and the length and width of geomembrane sample 69 are both larger than GCL sample 70; after the sample preparation is completed, turn on the power of each part of the instrument, operate the vertical actuator 19 to shrink, so that the upper shear box 32 is separated from the lower shear box, and leave enough space, through eight upper fixing bolts 60. Firmly fix the upper gripping toot...

Embodiment 2

[0092] Example 2: Geomembrane-clay interface dynamic shear test

[0093] Based on the large-scale multifunctional interface dynamic shear tester proposed by the present invention, the working process of carrying out the geomembrane-clay interface dynamic shear test is mainly divided into three stages: test preparation stage, test progress stage, and test end stage.

[0094] Test preparation stage: First, cut and prepare geomembrane sample 69 and clay sample 71 according to the size of the upper and lower shear boxes. The length and width of geomembrane sample 69 are larger than the size of the shear box. After the sample preparation is completed, turn on the power of each part of the instrument, operate the vertical actuator 19 to shrink, so that the upper shear box 32 is separated from the lower shear box, and leave enough space to pass through the eight upper fixing bolts. 60. Firmly fix the upper gripping tooth plate 56 on the lower surface of the upper shear box 32, and ma...

Embodiment 3

[0098] Embodiment 3: clay direct shear test

[0099] Based on the large-scale multifunctional interface dynamic shear tester proposed by the present invention, the working process of carrying out the clay direct shear test is mainly divided into three stages: the test preparation stage, the test progress stage, and the test end stage.

[0100] Test preparation stage: first, prepare a certain amount of clay sample 71 according to the volume of the upper and lower shear boxes, and the clay sample 71 is prepared by mixing in advance according to the set moisture content; turn on the power of each part of the instrument, and operate the vertical actuator 19 shrinks, the upper shear box 32 is separated from the lower shear box, and there is enough space left; then, unscrew the actuator fixing screw 43 of the fixed horizontal fixed plate 30 and the lower shear box rear bracket 41, and the two are disengaged. Open, the lower shear box is pushed along the horizontal guide rail 17 to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com