A preparation method of nano-silver and nano-zinc oxide dual-phase deposition of zinc-doped nano-hydroxyapatite and the resulting material

A technology of nano-hydroxyapatite and nano-zinc oxide, which is applied in metal material coating technology, pharmaceutical formulations, liquid chemical plating, etc., can solve the problems of fast release speed, inconspicuous antibacterial effect, inconspicuous long-term antibacterial effect, etc. , to achieve the effect of improving biological activity, improving antibacterial performance and accelerating recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

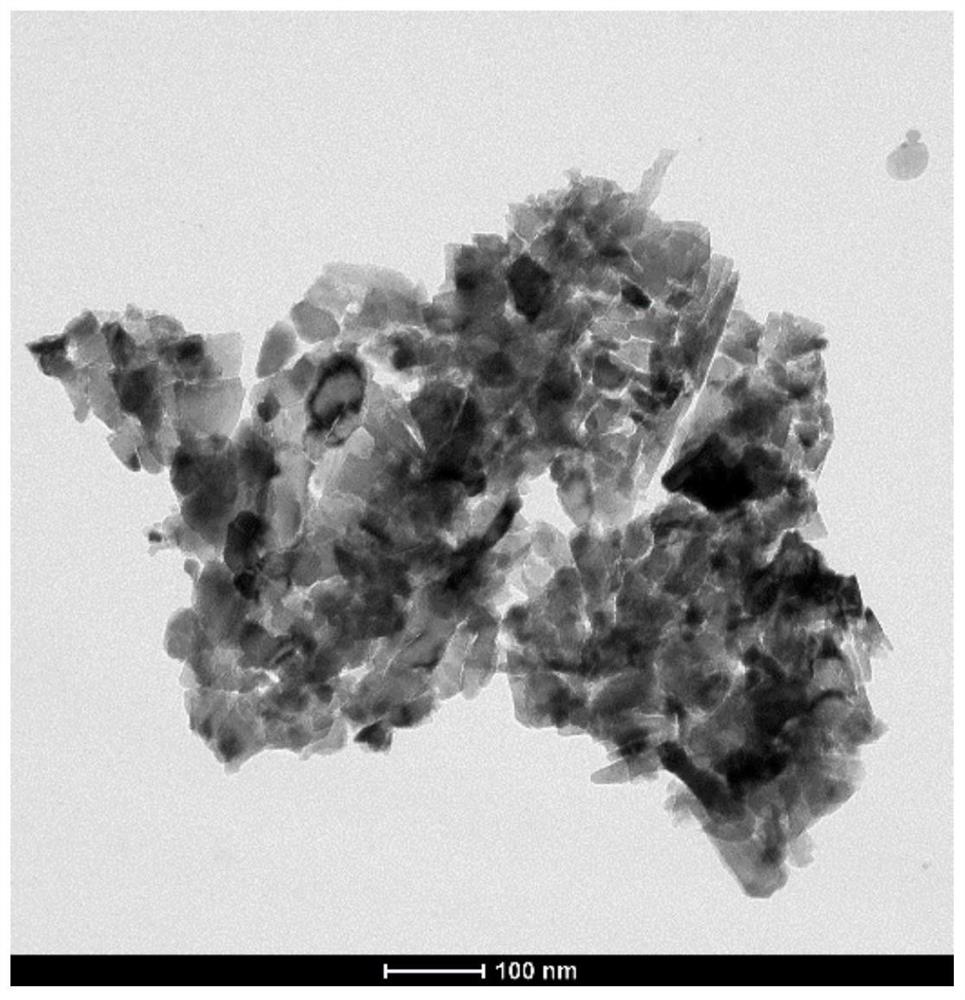

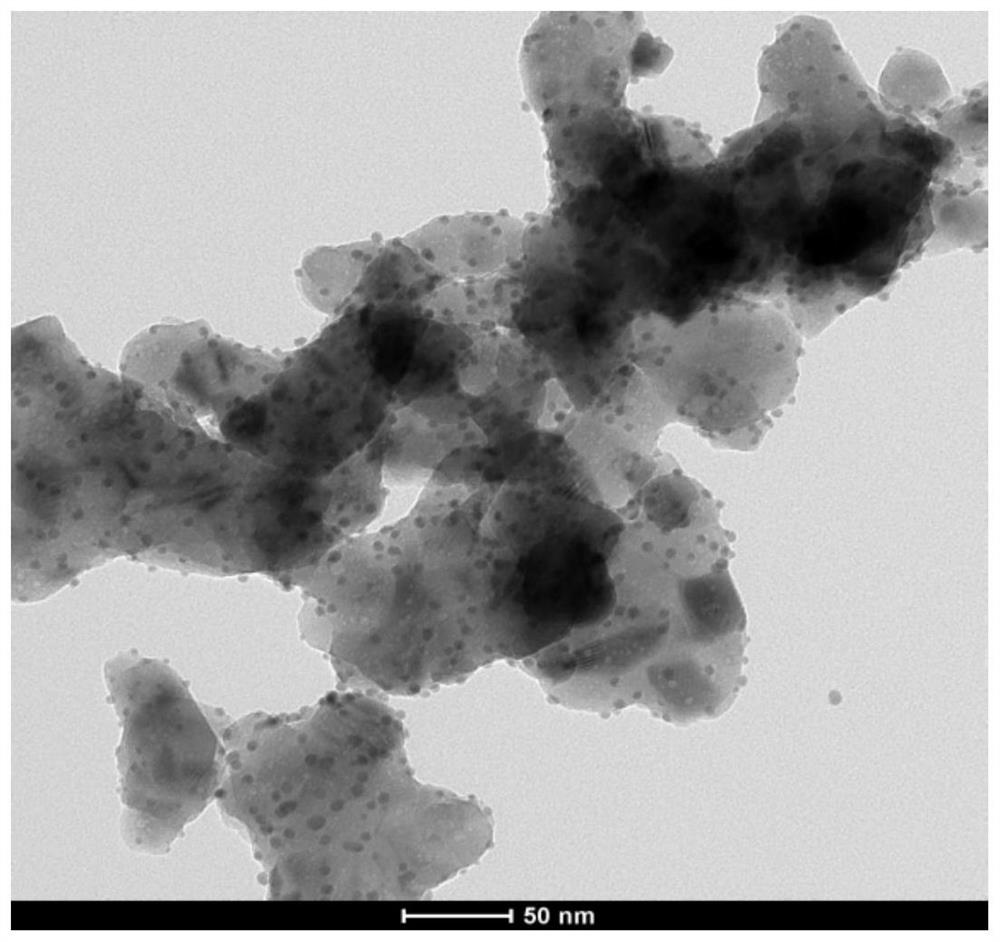

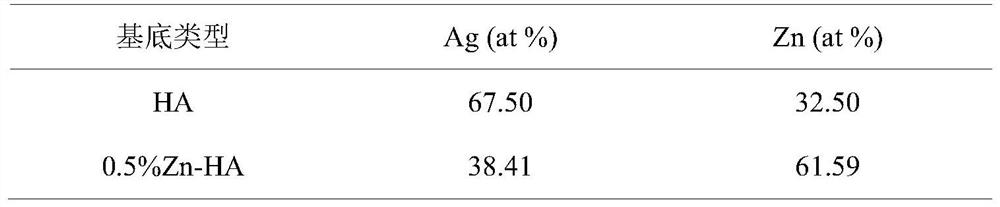

Image

Examples

Embodiment 1

[0024] A method for preparing zinc-doped nano-hydroxyapatite by dual-phase deposition of nano-silver and nano-zinc oxide, comprising the following steps:

[0025] Step 1: Zinc ion doping: Under rapid stirring conditions, add the phosphoric acid solution containing zinc nitrate dropwise to the calcium hydroxide suspension for reaction. After 6 hours of reaction, pass centrifugation, ball milling, aging, washing, Drying for 12 hours and calcining at 750° C. for 2 hours produces zinc-doped nano-hydroxyapatite.

[0026] Wherein, the molar ratio of the sum of the Zn atoms in the zinc nitrate and the Ca atoms in the calcium hydroxide to the P atoms in the phosphoric acid is 1.67:1. The atomic mass of Zn in zinc nitrate accounts for 0.5% of the atomic mass of Zn in zinc nitrate and the atomic mass of Ca in calcium hydroxide.

[0027] Step 2: nano-zinc oxide deposition: add the product of step 1 into the zinc nitrate solution, and drop an appropriate amount of ammonia water to produc...

Embodiment 2

[0036] A method for preparing zinc-doped nano-hydroxyapatite by dual-phase deposition of nano-silver and nano-zinc oxide, comprising the following steps:

[0037] Step 1: Zinc ion doping: Under rapid stirring conditions, add the phosphoric acid solution containing zinc nitrate dropwise to the calcium hydroxide suspension for reaction. After 6 hours of reaction, pass centrifugation, ball milling, aging, washing, Drying for 12 hours and calcining at 450° C. for 2 hours produces zinc-doped nano-hydroxyapatite.

[0038] Wherein, the molar ratio of the sum of the Zn atoms in the zinc nitrate and the Ca atoms in the calcium hydroxide to the P atoms in the phosphoric acid is 1.67:1. The atomic mass of Zn in zinc nitrate accounts for 1% of the atomic mass of Zn in zinc nitrate and the atomic mass of Ca in calcium hydroxide.

[0039] Step 2: nano-zinc oxide deposition: add the product of step 1 into the zinc nitrate solution, and drop an appropriate amount of ammonia water to produce ...

Embodiment 3

[0046] A method for preparing zinc-doped nano-hydroxyapatite by dual-phase deposition of nano-silver and nano-zinc oxide, comprising the following steps:

[0047] Step 1: Zinc ion doping: Under rapid stirring conditions, add the phosphoric acid solution containing zinc nitrate dropwise to the calcium hydroxide suspension for reaction. After 6 hours of reaction, pass centrifugation, ball milling, aging, washing, Drying for 12 hours and calcining at 600° C. for 2 hours produces zinc-doped nano-hydroxyapatite.

[0048] Wherein, the molar ratio of the sum of the Zn atoms in the zinc nitrate and the Ca atoms in the calcium hydroxide to the P atoms in the phosphoric acid is 1.67:1. The atomic mass of Zn in zinc nitrate accounts for 0.5% of the atomic mass of Zn in zinc nitrate and the atomic mass of Ca in calcium hydroxide.

[0049] Step 2: nano-zinc oxide deposition: add the product of step 1 into the zinc nitrate solution, and drop an appropriate amount of ammonia water to produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com