Micro-bubble purifying apparatus and micro-bubble purifying method

A purification device and micro-bubble technology, applied in chemical instruments and methods, mixing methods, separation methods, etc., can solve the problems of small contact area between capture body and flue gas, escape of fine dust, large volume of capture body, etc., to achieve enhanced gas Effects of liquid mixing, increased contact frequency, and reduced chance of escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

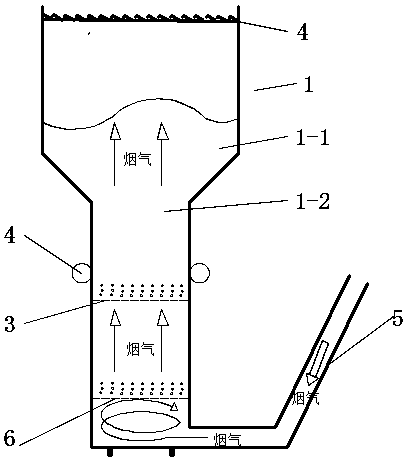

[0022] like figure 1 As shown, a microbubble purification device includes a purification chamber 1, an ultrasonic generator 2, a gas distributor 3, a louver type demister 4 and a tangential air inlet 5, and the purification chamber 1 includes a separation chamber 1-1 And the contact chamber 1-2, the diameter of the separation chamber 1-1 is greater than the diameter of the contact chamber 1-2, the bottom of the separation chamber 1-1 shrinks to the same diameter as the contact chamber 1-2, forming a funnel-shaped connecting section, the contact chamber 1-2 is fixedly connected to the lower part of the separation chamber 1-1; the bottom of the contact chamber 1-2 is sealed, and is provided with a liquid inlet and a sewage outlet, and the inside is filled with purification liquid; the contact chamber 1-2 is axially arranged There are at least two layers of gas distributors, which divide the contact chamber 1-2 into multiple cavities, among which the lowermost cavity is an air in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com