Turbulent ball tower convenient for desulfurization

A turbulent ball and main body technology, which is applied in the field of turbulent ball towers, can solve the problems of substandard exhaust gas emission, difficult dust removal and desulfurization treatment, etc., and achieve the effect of strengthening purification effect, strengthening strength and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

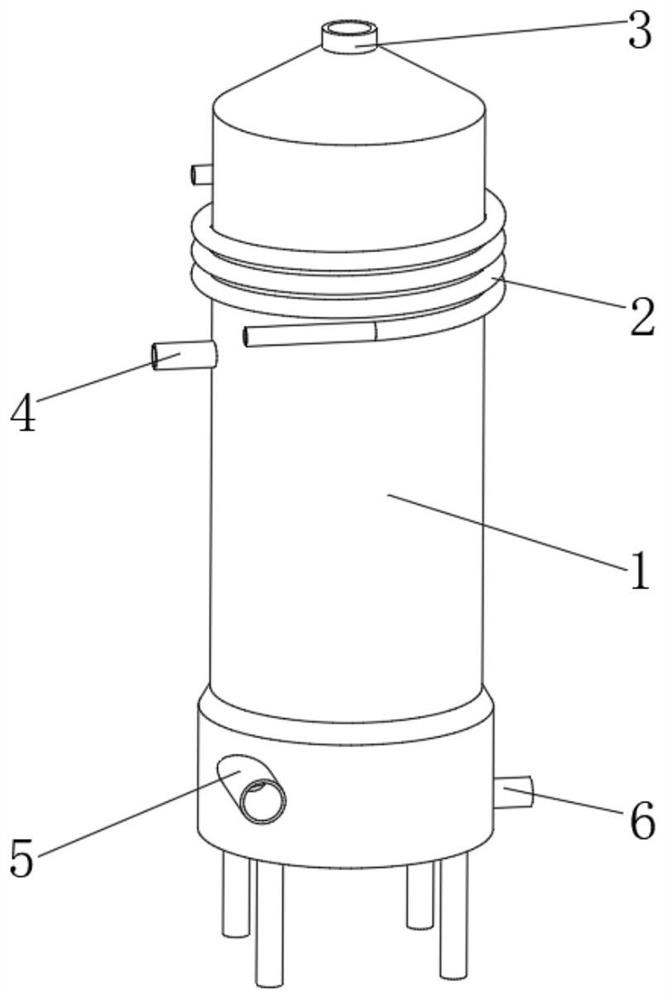

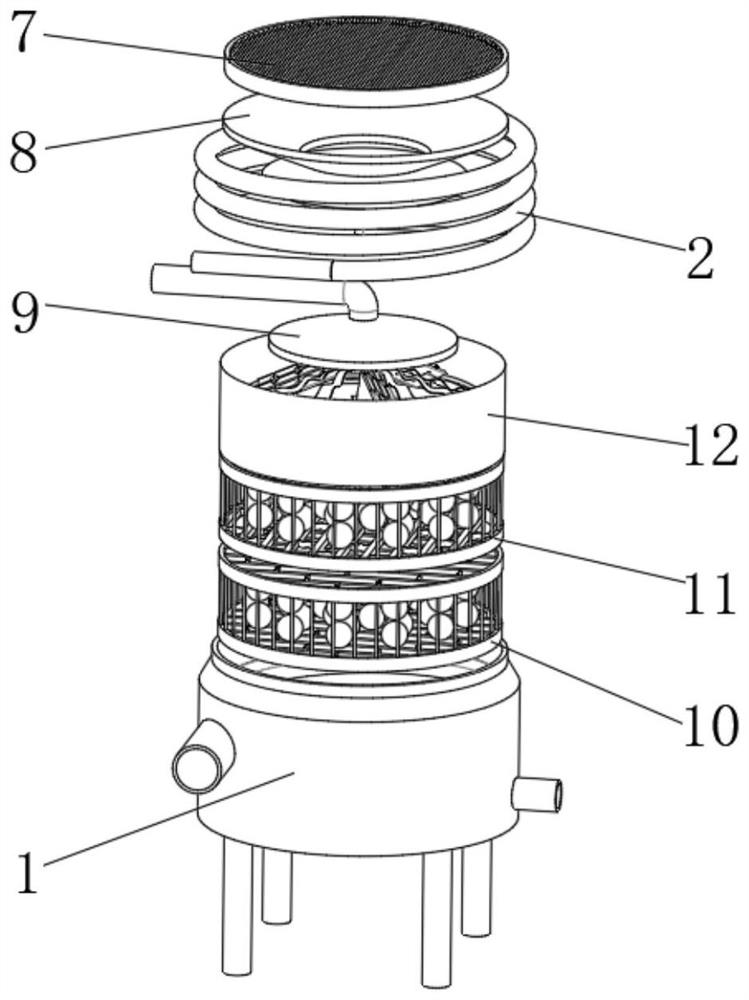

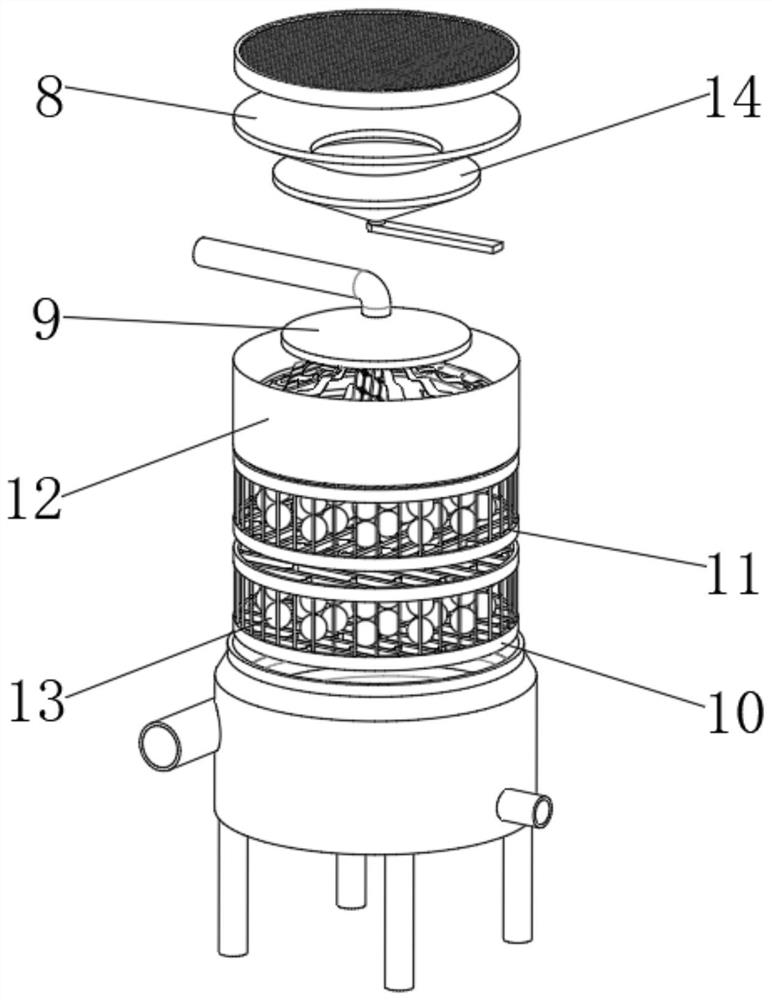

[0034] A kind of turbulent ball tower that is convenient for desulfurization, such as Figure 1-6As shown, it includes a main body 1, the outer wall of one side of the main body 1 is provided with an air intake pipe 5, and the outer wall of the other side of the main body 1 is installed with a delivery pipe 4, and the end of the delivery pipe 4 located in the main body 1 is welded with a shower head 9, The other end of the delivery pipe 4 is connected with a spray liquid supply device, and the main body 1 is also provided with a turbulent ball purification mechanism and a barrier strip purification mechanism, and the barrier strip purification mechanism is arranged between the turbulence ball purification mechanism and the spray head 9 , the barrier strip purification mechanism includes an annular seat 12 and a connecting seat 24, the annular seat 12 is welded to the inner wall of the main body 1, the top and bottom of the annular seat 12 are bucket-shaped slope structures, and...

Embodiment 2

[0043] A kind of turbulent ball tower that is convenient for desulfurization, such as figure 2 , image 3 As shown, in order to further improve the desulfurization effect; this embodiment makes the following improvements on the basis of embodiment 1: the inner wall of the main body 1 is welded with a bucket-shaped baffle 8, and the inner wall of one side of the main body 1 is installed with a bucket through a support frame. The conical baffle 14 that is suitable for the baffle 8, the conical baffle 14 is located below the bucket-shaped baffle 8, and the central axis of the conical baffle 14 coincides with the central axis of the bucket-shaped baffle 8, and the circumference of the main body 1 The outer wall is provided with a circulating liquid pipe 2 with a spiral structure; the input and output ends of the circulating liquid pipe 2 are connected with a cooling liquid supply device; by setting the circulating liquid pipe 2, it can play a cooling role, facilitate the condensa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com