Modification method of catalyst carrier for producing ethylene glycol through hydrogenation of oxalate, and catalyst and applications thereof

A technology of catalyst carrier and oxalate, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Solve the problems of large differences in silicon chemical properties, etc., and achieve the effects of easy-to-obtain raw materials, simple and low preparation process and production cost, high ethylene glycol selectivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Fumed silica modification:

[0021] Weigh two samples of 6g of fumed silica, dissolve them in 600mL of NaCl solution with a mass concentration of 20%, and stir thoroughly; then, adjust the pH of the solution to 4.0 with hydrochloric acid with a mass concentration of 5%; then, adjust the concentration 25ml and 50ml of 0.1mol / L NaOH solution were added to the above two solutions and mixed thoroughly for 30min; finally, the above suspension was filtered and washed until the filtrate was neutral, then dried at 120°C, respectively Marked as SiO 2 -A and SiO 2 -B.

Embodiment 2

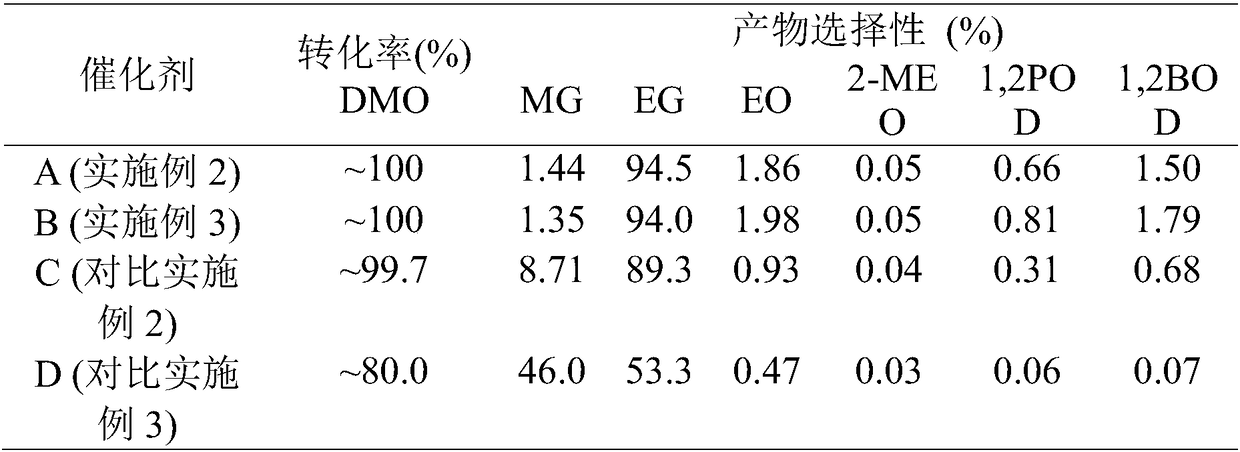

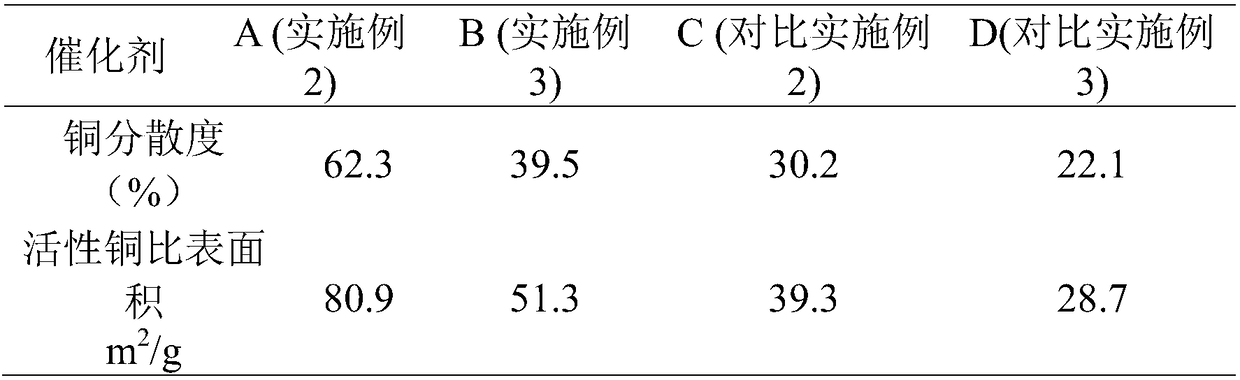

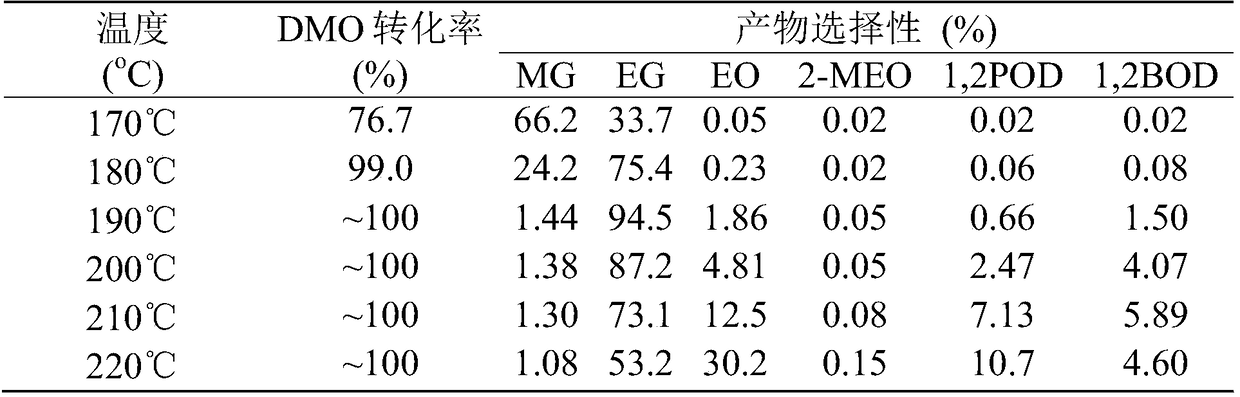

[0023] Cu(NO 3 ) 2 Prepare a 0.3mol / L aqueous solution, measure 157ml of the solution and place it in a beaker, slowly add ammonia water dropwise while stirring, and stop when the pH of the solution in the beaker is 9.5-10.5. Take by weighing the modified fumed silica SiO in 4g embodiment 1 2 -A, add the above cuproammonia solution into the beaker, stir and age in a water bath at 30°C for 4 hours, then heat up to 90°C to distill ammonia until the pH value of the solution in the beaker is 7-8 and stop. The resulting precipitate was filtered, washed until the pH of the filtrate was about 7, and stopped. The washed precipitate was dried at 120°C for 12h, calcined at 450°C for 4h, pressed and crushed to 20-40 mesh, and reduced before reaction to obtain catalyst A: 20wt% Cu / SiO 2 .

Embodiment 3

[0025] The preparation steps are the same as in Example 2, and the modified fumed silica SiO in 4g of Example 1 is weighed. 2 -B. Prepared Catalyst B: 20wt% Cu / SiO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com