Millstone type natural graphite fine grinding and screening device

A natural graphite, fine grinding technology, used in cocoa, grain processing, food science and other directions, can solve the problems of uneven graphite grinding, prolonged processing time, low productivity, etc. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

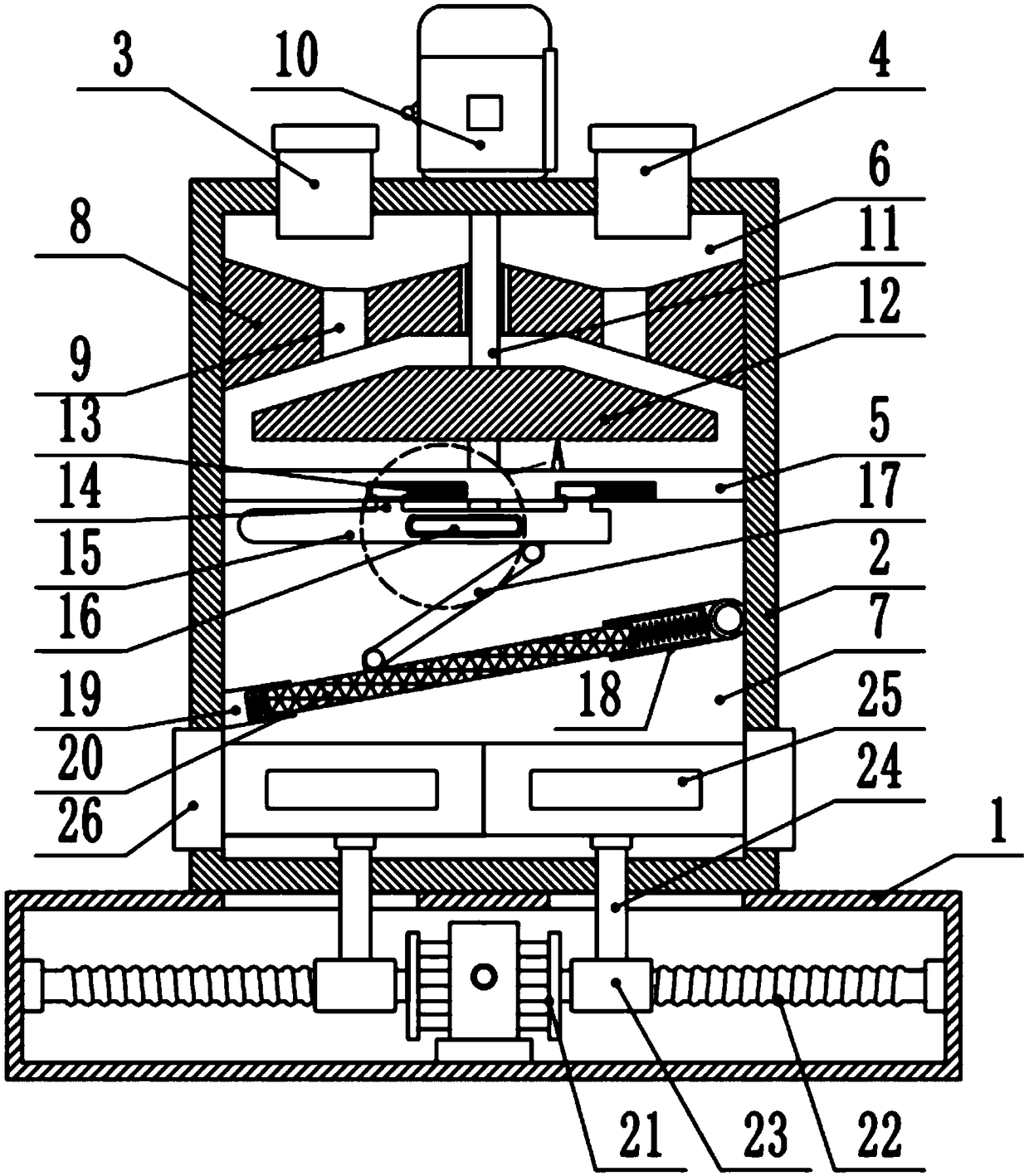

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

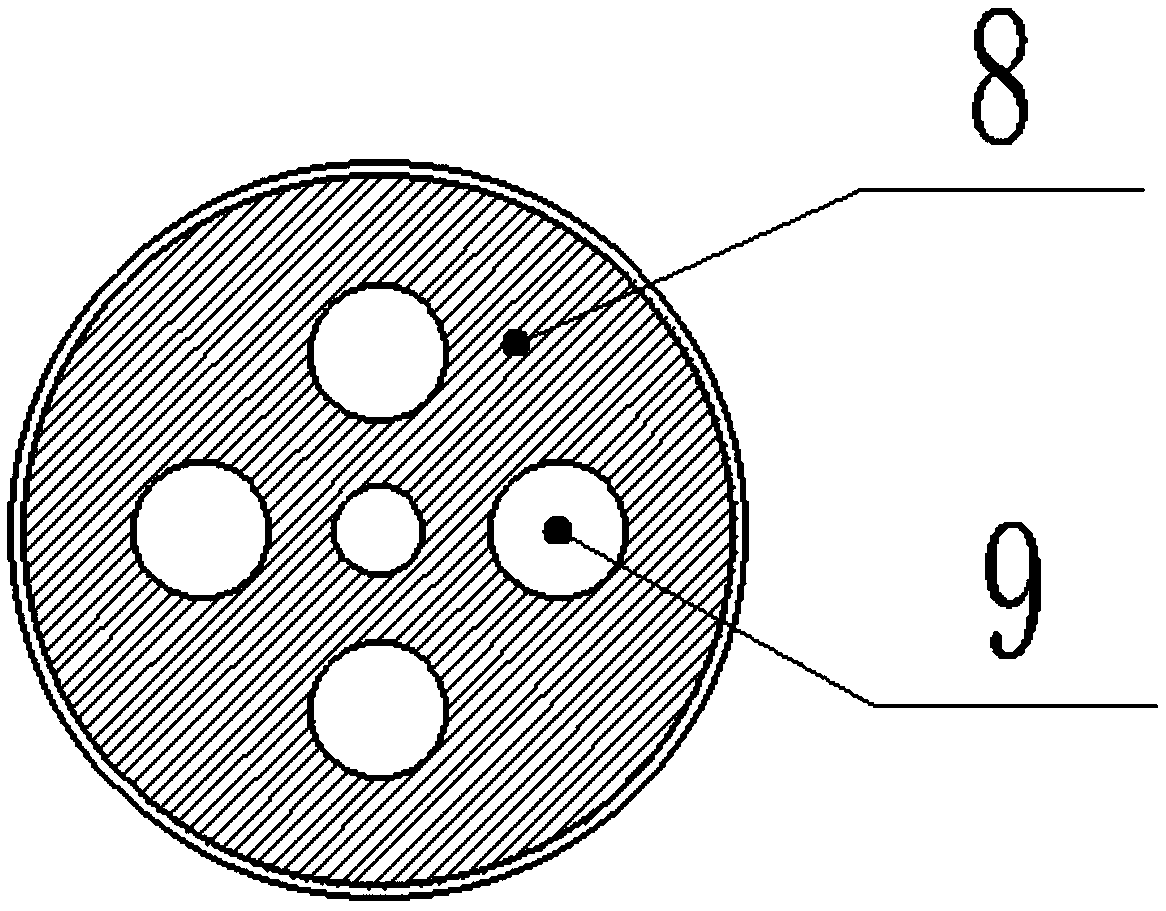

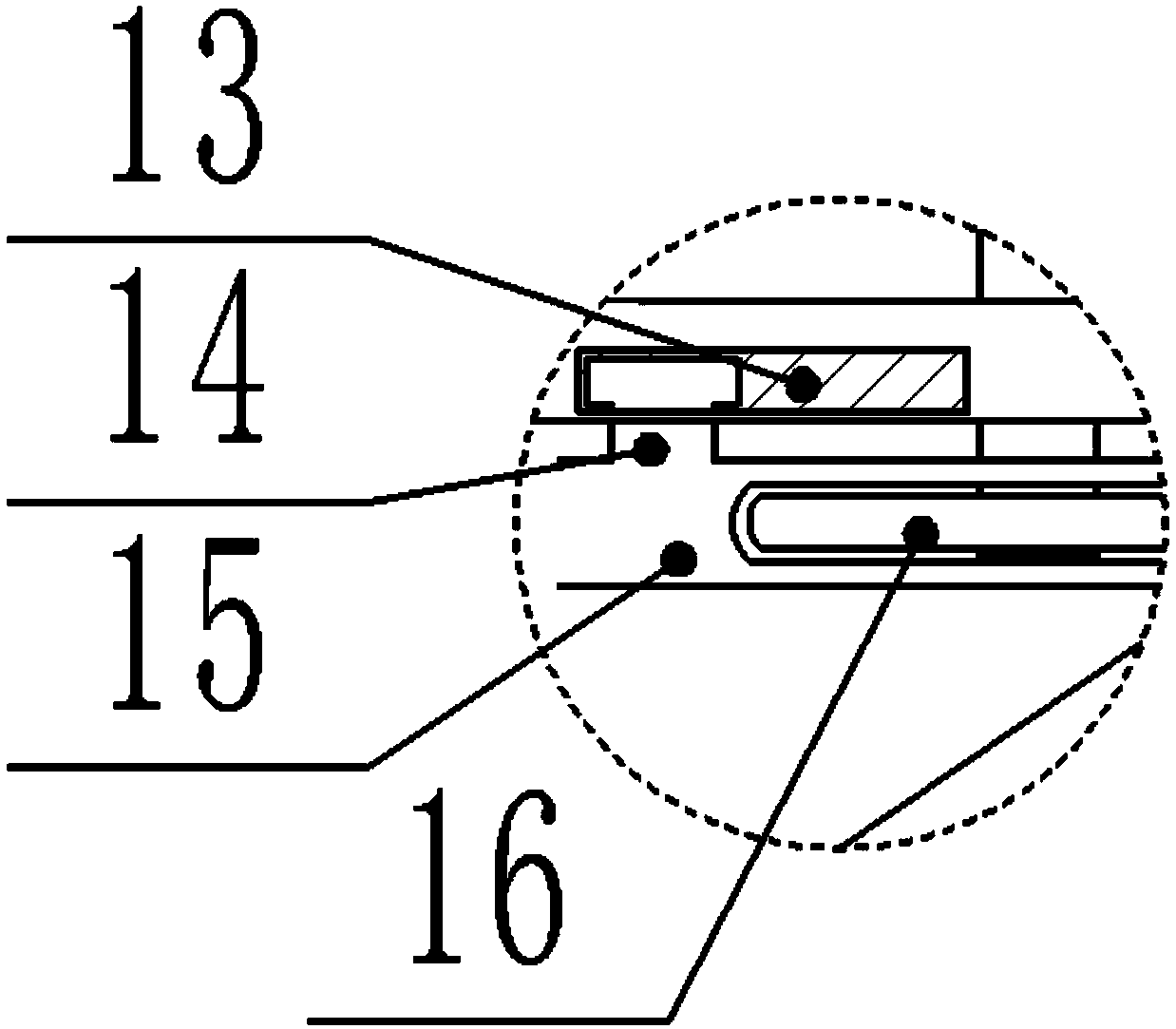

[0020] see Figure 1-3 , a disc type natural graphite fine grinding and screening device, comprising a base 1, a grinding box 2, a grinding box screen 20, a second drive motor 21 and a receiving box 25, the base 1 is provided with a grinding box 2, and the grinding box 2 and the base 1 are fixedly connected by bolts, and the left and right parts of the upper side of the grinding box 2 are symmetrically opened with a left graphite raw material inlet 3 and a right graphite raw material inlet 4, and the left graphite raw material inlet 3 and the right graphite raw material inlet 4 are both A feeding pipe is embedded and installed, and a sealing cover is threaded on the feeding pipe. A sliding frame 5 is welded horizontally in the middle of the grinding box 2. The upper part of the sliding frame 5 is a grinding chamber 6, and the lower part is a screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com