Method for preventing steel clamping of single-machine-frame rolling mill

A single stand, rolling mill technology, applied in the safety equipment of rolls, metal rolling, metal rolling, etc., can solve the problems of large production capacity loss, affecting fuel consumption, and high equipment renovation costs, and achieve the requirements of reducing the furnace temperature, reducing Loss of production capacity and the effect of reducing loss of roll wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

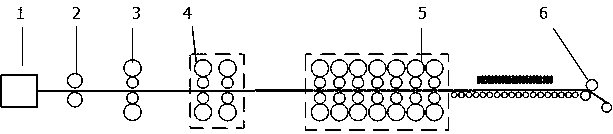

Method used

Image

Examples

Embodiment

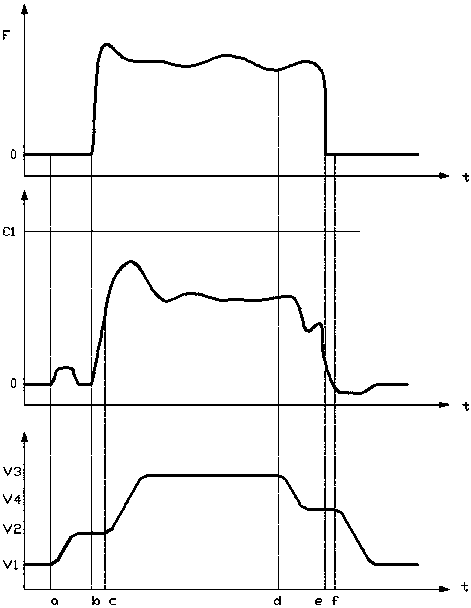

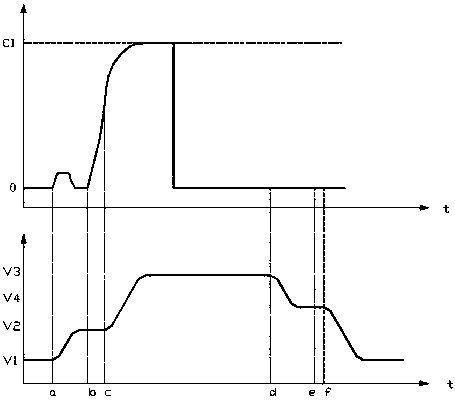

[0052] The method for preventing steel jamming in a single-stand rolling mill of a certain enterprise is implemented on the R2 frame of the 2050 hot-rolling line. The speed-down function start signal is judged by the basic automation computer L1 according to the actual value of the current sent by the transmission control unit: the system maximum current of the motor C1=9870A, take the current limit value C2 as 75%*C1. Then when the actual value of the motor current ≥ C2 (C2=75%*C1=7402.5A), the deceleration function is started, and the lower limit of the speed is 1m / s;

[0053] When reducing the speed given value of the rolling mill, in order to prevent the slab from slipping during the speed switching process, it is necessary to limit the maximum acceleration. In this embodiment, the acceleration is limited to 2m / s 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com