Automatic woodworking machine tool

A woodworking machine tool and machine tool technology, which is applied to wood processing appliances, manufacturing tools, forming/shaping machines, etc., can solve problems such as difficulty in implementation, large equipment, and complex structure, so as to improve processing efficiency and reduce the trouble of changing tools. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

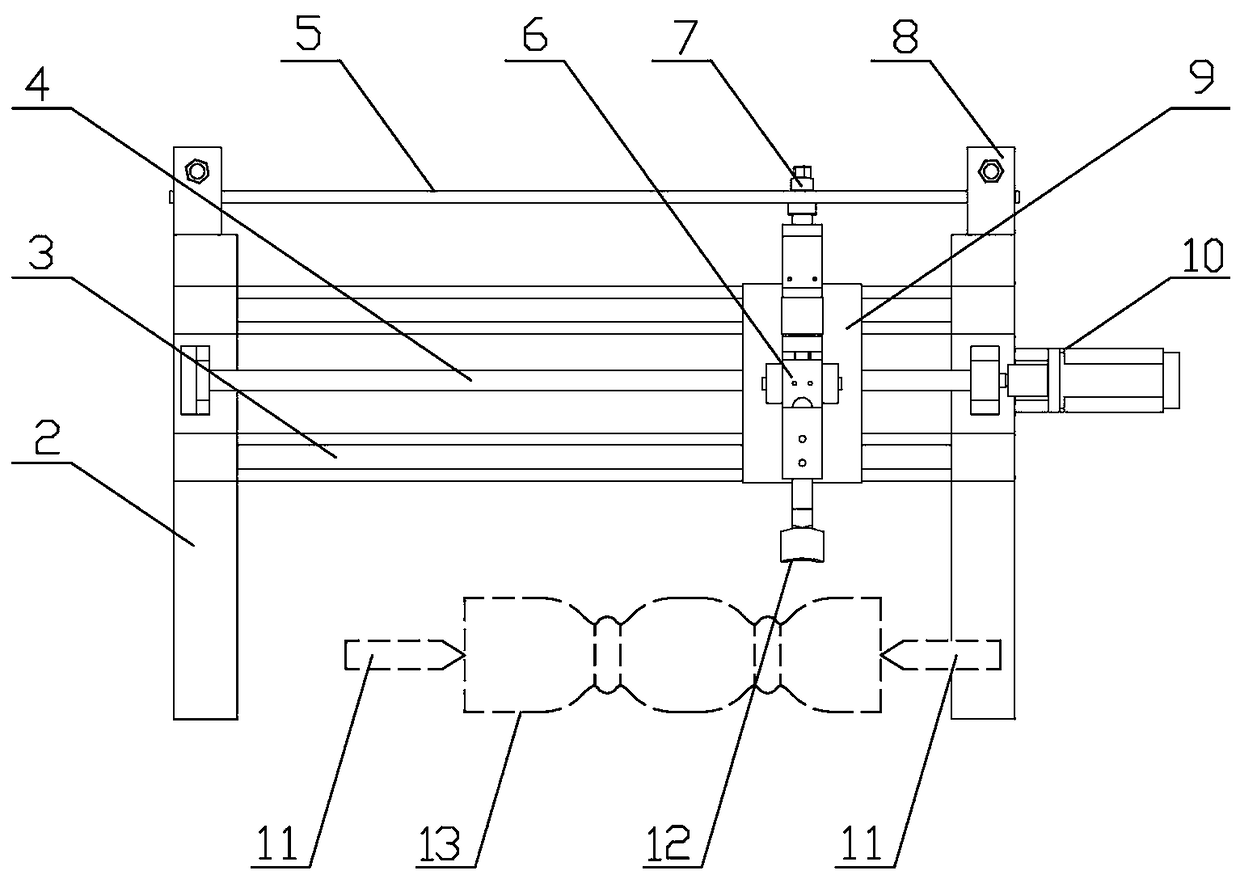

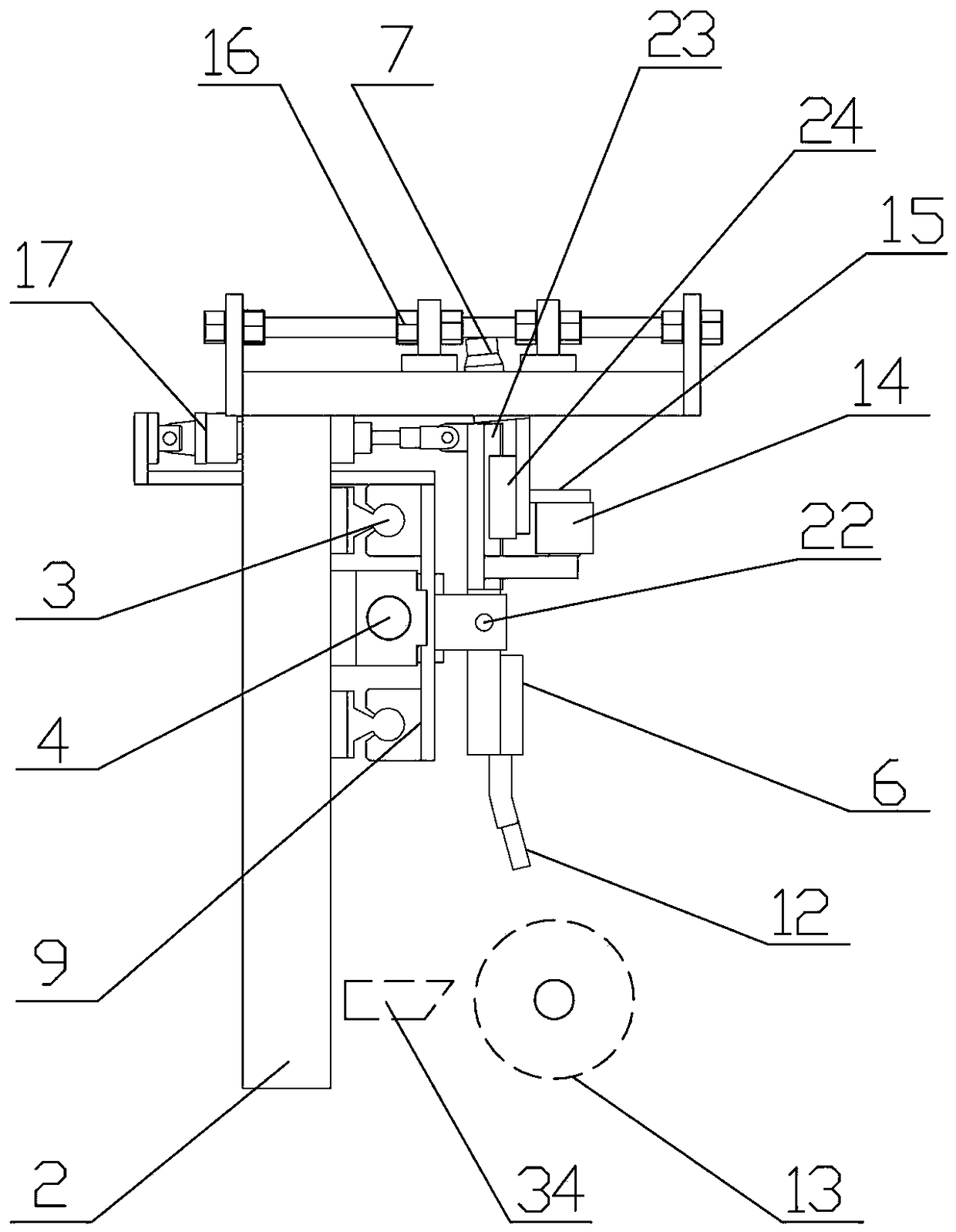

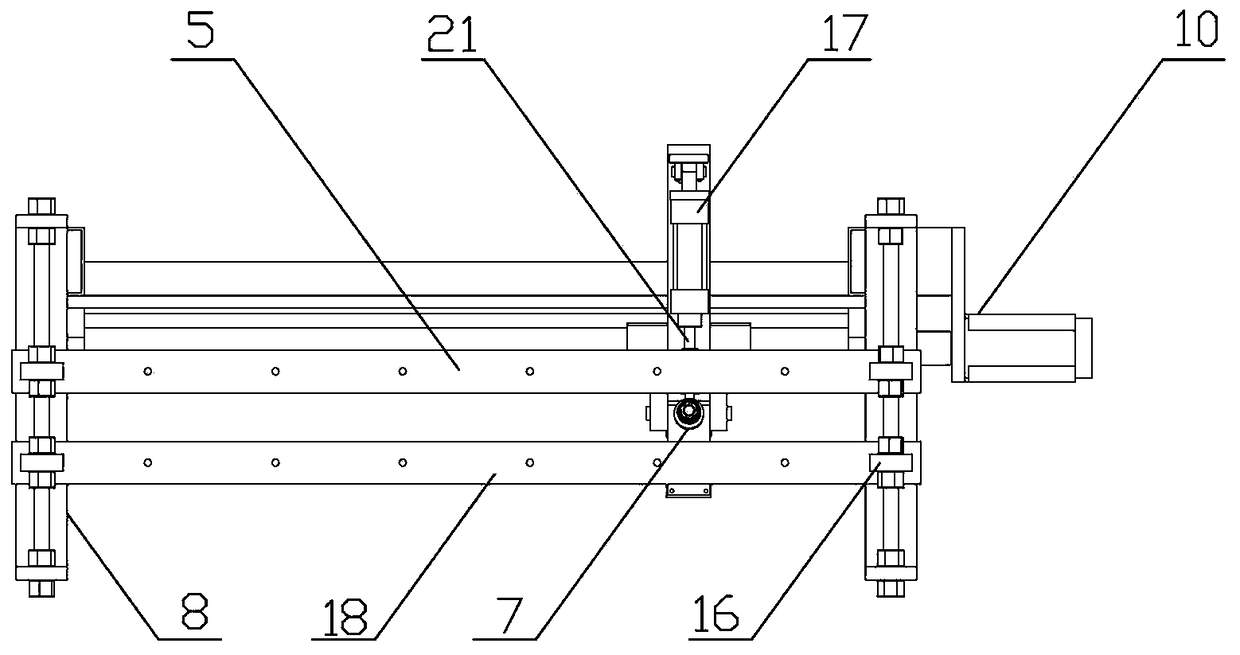

[0027] figure 1 , figure 2 , image 3 , Figure 4 It is a schematic diagram of the tool post mechanism of an automatic woodworking machine tool. There is a column 2 and a beam 8 installed on the machine tool mechanism. Above the column, there is a guide rail 3 and a screw 4 connected to the servo motor 10; there is a tool post bearing fixing plate 9, and the middle part is equipped with a The nut, the upper and lower parts are provided with grooves that can match with the guide rail, and the front and rear cylinders 17 are arranged on the top of the tool rest bearing fixed plate; The middle part of the tool holder bearing fixed plate is hinged 22, and the upper part of the tool holder is hinged with the cylinder shaft 21;

[0028] The other side of the knife rest top is provided with a vertical guide rail 23 and a vertical groove 24, the vertical groove is fixed on the vertical frame 15, the upper end of the vertical frame is connected with the conical wheel 7, the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com