Spray head device of 3D printer

A technology of 3D printers and nozzles, applied in the field of 3D printing, can solve the problems of affecting printing, easily remaining printing materials, and affecting printing effects, etc., and achieve the effects of reducing sand holes, increasing diversity, and preventing condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail:

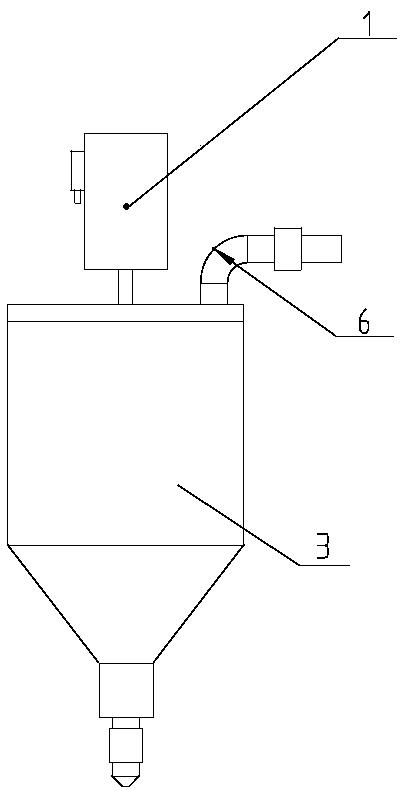

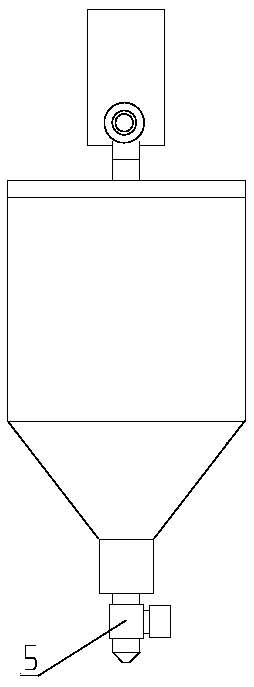

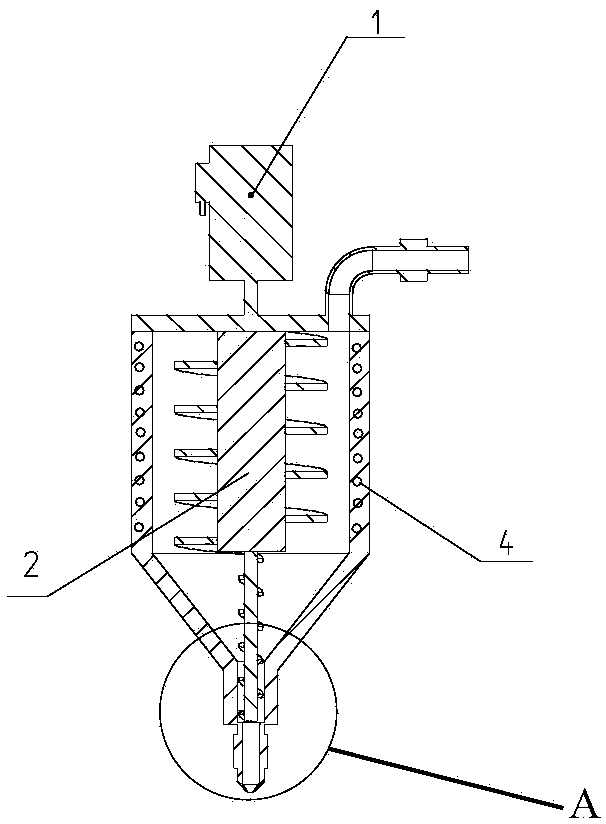

[0024] see Figure 1 to Figure 5 , a nozzle device of a 3D printer, comprising a nozzle housing 3 for accommodating printing materials, a power unit 1 is arranged on the top of the nozzle housing 3, and the output end of the power unit 1 is connected to a nozzle for stirring printing materials and extruding the printing materials. out of the stirring device 2, the bottom of the nozzle housing 3 is provided with a controllable one-way valve 5, the top of the nozzle housing 3 is also provided with an air extraction device 6 for extracting the gas, and the surrounding of the nozzle housing 3 is provided with A heating device 4 for melting printing materials, the nozzle housing 3 includes a cylindrical housing, a conical housing connected to the lower part of the cylindrical housing, and a nozzle connected to the lower part of the conical housing, and the cylindrical hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com