Centrifugal casting method of metal piece

A technology for centrifugal casting and metal parts, applied in the field of centrifugal casting of metal parts, can solve the problems of difficult control of process parameters, high-chromium metal parts with pores, large surface roughness, etc. Small margin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

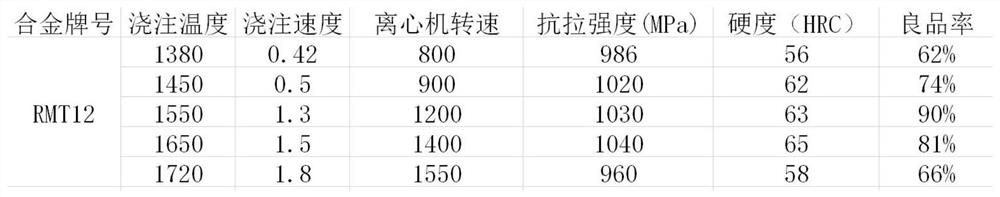

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0035] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

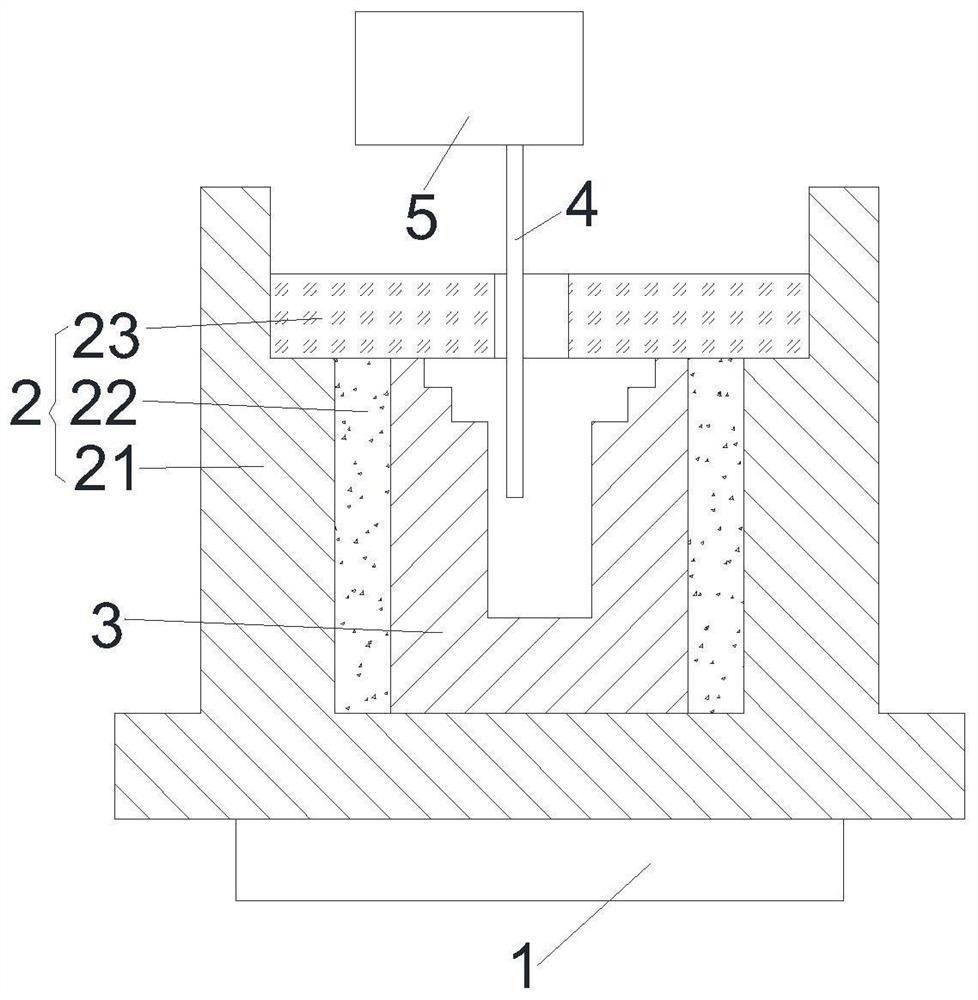

[0036] see Figure 1-Figure 2

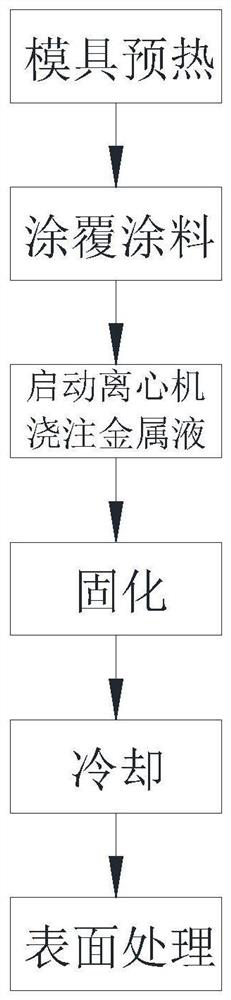

[0037] A centrifugal casting method for a metal piece, comprising the following steps:

[0038] S1: mold preheating

[0039] Before preheating the mold, clean up the rust, dust, residual paint, etc. on the surface of the mold, and strictly control the oil pollution, and there must be no oil pollution. Heat the mold to between 500°C and 550°C; the material used for the mold is heat-resistant cast iron, the demoulding dimension of the inner cavity of the mold is between 1°C and 1.3°C, and the heating time in the mold is about 5 minutes. He...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com