Vacuum pressurizing casting machine

A technology of vacuum pressurization and casting machine, applied in the field of metal casting machines, can solve the problems of low product density, low qualification rate, large loss, etc., and achieve the effects of strong anti-interference ability, high yield and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

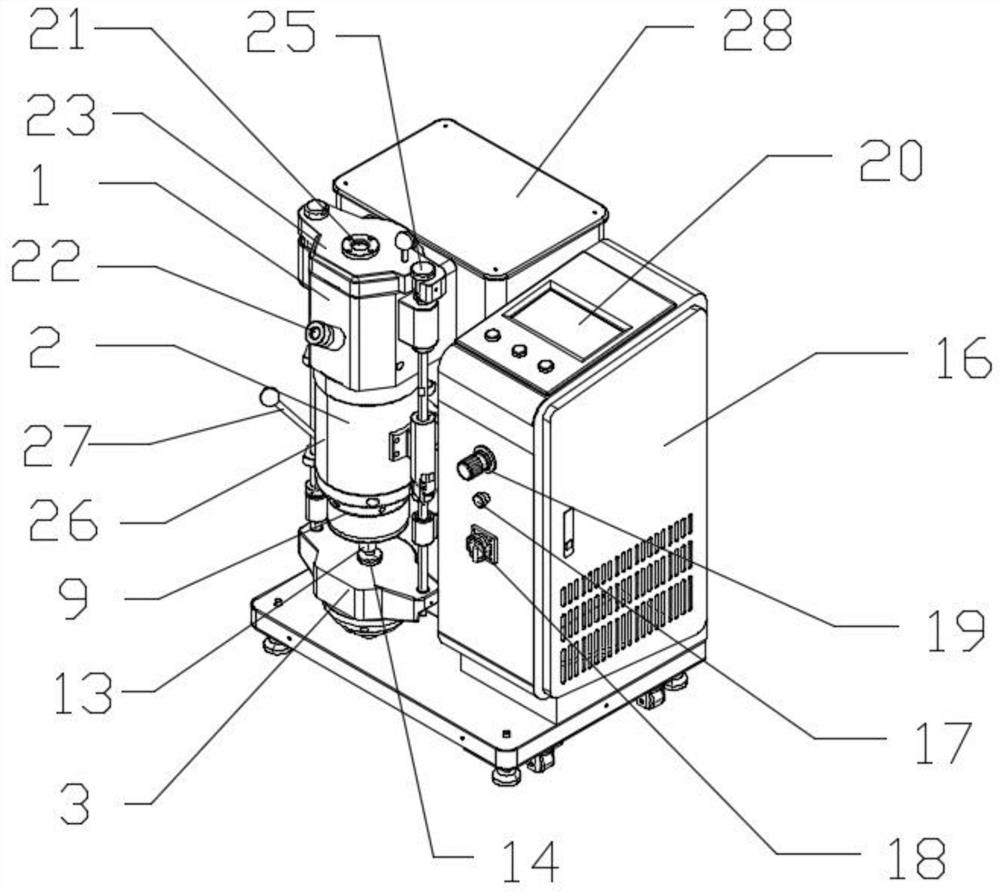

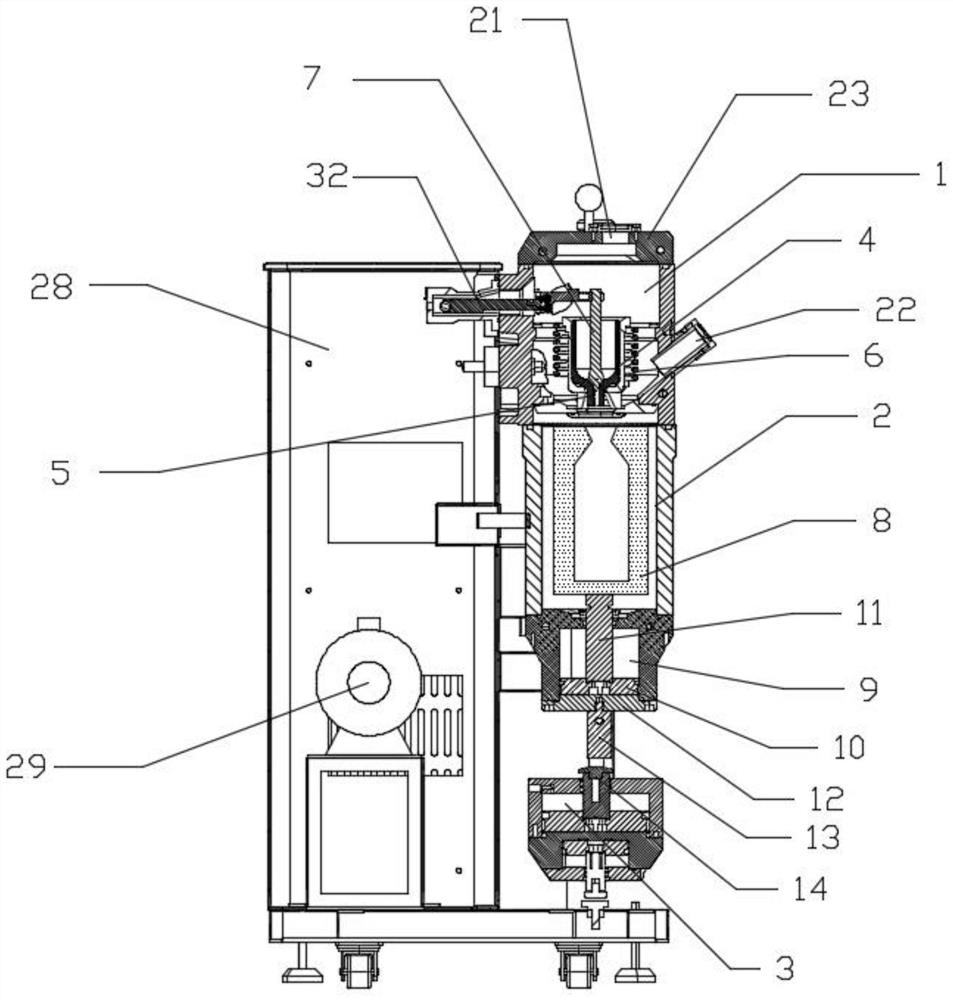

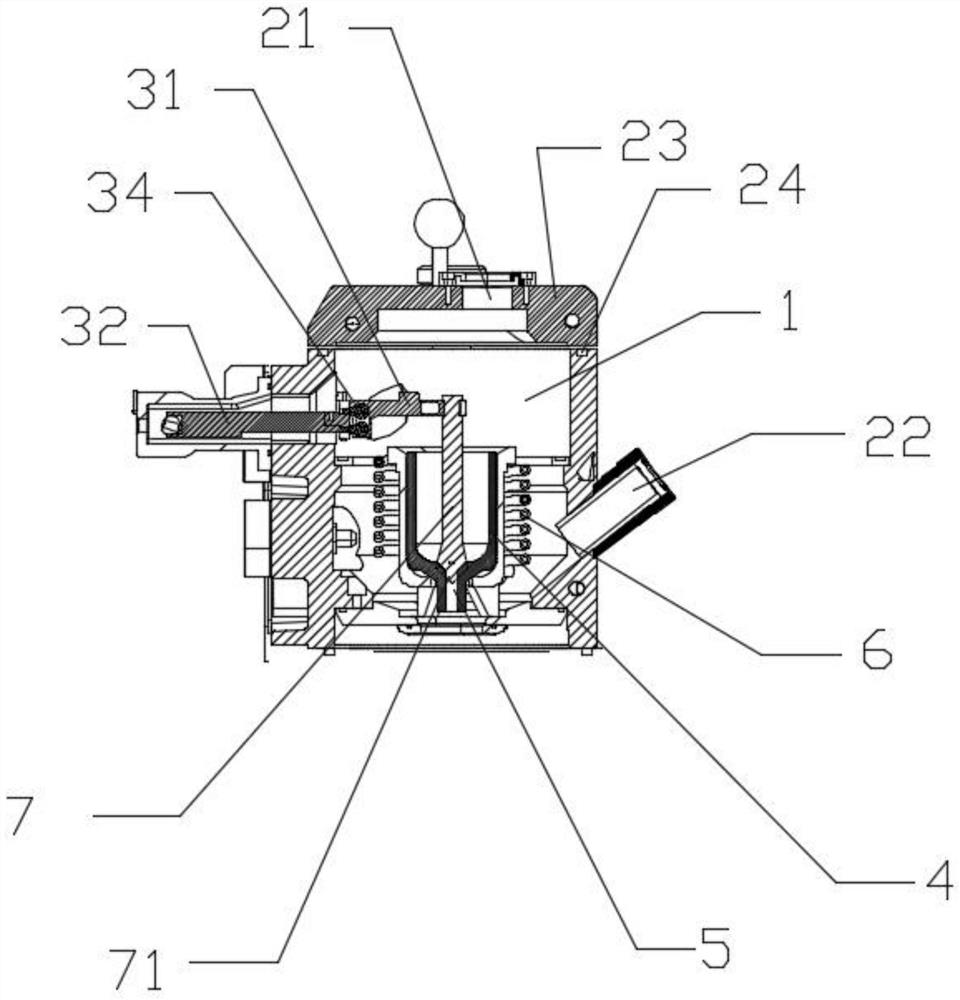

[0025] refer to Figure 1-5 , a vacuum pressurized casting machine, comprising a furnace chamber (1), a mold chamber (2) is arranged below the furnace chamber (1), and a cylinder chamber (3) is arranged below the mold chamber (2). The cylinder chamber (3) pushes out upwards to seal the bottom of the mold chamber (2), and the metal flows into the mold chamber (2) for molding after melting in the furnace chamber (1).

[0026] Among them, a crucible (4) is installed in the furnace chamber (1), a liquid leakage hole (5) is arranged at the bottom of the crucible, an induction coil (6) is arranged outside the crucible (4), and a sealing rod (7) is arranged inside the cruci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com